<strong>Solar</strong> Space <strong>Heat</strong>ingThe liberal use of threaded unions allows <strong>for</strong> easyremoval of components <strong>for</strong> repair or replacement.Fortunately, I had installed unions around the pump withserviceability in mind, so I simply closed some valvesand removed the section. I unscrewed the fittings oneach side of the pump, reversed it, and reinstalled it.The moment the pump began to run, I watched theincoming temperature gauge rise to over 220°F (104°C)from the stagnant hot water in the collectors. In a fewminutes, it settled down to a nominal 155°F (68°C),which seemed to be the system’s normal capacity(more on that later).I wholeheartedly recommend that all systems have aliberal sprinkling of unions to allow <strong>for</strong> servicedisassembly. I also found some leaks around my heatexchanger, and rectified that by removing the wholeassembly and tightening the fittings.PV & Collector ProblemsIn the first few days of full sun, I noticed that the pumpdidn’t kick in until after 10:30 AM. I first thought that thesolar-electric panel that runs the circulation pump wasunderpowered. On the third sunny morning, I went outand looked at the PV panel. I saw that I had mounted itup slope from the air vent I had installed on a 6 inch (15cm) extension above the collectors, and the air vent wasshadowing the PV! So I moved it over by a foot andfixed that silly mistake!When I mentioned to Naoto that my operatingtemperature was a nominal 155°F (68°C), he wassurprised, since the design spec is closer to 180°F(82°C). He had been having trouble with other SunEarthEmpire series units underper<strong>for</strong>ming, and contacted thefactory.The SunEarth engineers were very responsive andsoon learned that there was a manufacturing defect inthe units. They arranged with <strong>Solar</strong> Market to replaceThe air vent shaded the PV panels in the early morning,causing a delay in pump operation—Oops!those units that were already installed. The first set ofreplacements I received was not packed properly andthe panels were badly damaged in shipping. Almost fourmonths later, I finally have the new units, and must nowwait <strong>for</strong> a warm, dry day! Right now it’s inches of mudand raining hard, with snow in the <strong>for</strong>ecast! Check myWeb site <strong>for</strong> details on the new panels and theirper<strong>for</strong>mance.Underpowered Floor Circulating PumpsThe next setback came when the propane suppliercame to hook up the AquaStar heater. We couldn’t getthe heater to kick in, even though the circulating pumpwas running. I realized that mine is a closed system,and the AquaStar relies on a pressure difference of 10psi to turn on.This is fine in an open system. When you turn on afaucet, the outfeed pressure drops, turning the heaterburner on to the degree needed to bring the waterflowing through it to temperature. It looked like the pump(Taco 003 series) was underpowered. This was verydistressing!I called Naoto at <strong>Solar</strong> Market and he immediately droveover (a trip of more than an hour!) in his biodiesel<strong>Home</strong> <strong>Power</strong> #89 • June / July 200241

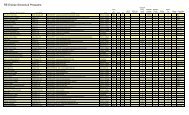

<strong>Solar</strong> Space <strong>Heat</strong>ingMarsden <strong>Heat</strong>ing System CostsItemCost (US$)2 SunEarth Empire series 4 x 8 foot collectors 952AquaStar 125BS propane water heater 6901,000 ft. Rehau radiant floor tube, 1 /2 inch (600 ft. used) 616Lumber <strong>for</strong> shed 580Copper pipe, fittings, valves, etc., 3 /4 inch 5002 El Sid PV-driven circulating pumps, 3 GPM 10 W 420Rheem storage tank, 80 gallons 3692 Taco circulating pumps, model 006, 120 VAC 332Secespol B 130 heat exchanger 2562 <strong>Solar</strong>ex SX-10M PV modules, 12 V, 10 W 212<strong>Solar</strong>ex SX-20M PV module, 12 V, 20 W 1802 Manifolds, 6 outputs & 6 valves <strong>for</strong> floor tubes 138Wayne PC2 utility pump, 60 gph at 40 feet of head 855 Temperature gauges 802 Amtrol 2 gal. expansion tanks, high temperature 76Check valve, light-action spring 24Amtrol air vent 9powered Mercedes. He brought a larger pump. Naotohas been unfailingly supportive and helpful throughoutthe entire project. I simply couldn’t have done it allwithout his help and advice. We were lucky that thelarger pump (Taco 007 series) that he brought was thesame brand and used the same size motor body as theunderpowered unit.The quick fix was to remove the motor from its housingand replace it with the larger motor and impeller. Thissaved a lot of work replumbing all the copper! Themodified pump created enough draw to pull a pressuredrop across the AquaStar and trigger it to fire up itsburners.After running this modified pump <strong>for</strong> several days, Inoticed that it ran hot—too hot to touch com<strong>for</strong>tably. Idecided to call the manufacturer, Taco, Inc. Theapplication engineers there were very helpful andreviewed my design thoroughly. They asked me to takeamp readings while the pump was running, and also rana lab simulation of my system configuration.Their conclusion was that I would be better served by a006 series pump. It comes with 3 /4 inch sweat fittingsrather than the 1 /2 inch sweat fittings that I had used withthe original 003 series unit. This model is also moreefficient electrically. The 007 model is rated at 0.7 amps,while the 006 model is rated at 0.52 amps. Both pumpsoperate at 120 VAC. I found that the rated amps are arough value, and the actual draw varies with theoperating temperature of thepump—cooler equals lower current.<strong>My</strong> pumps seem to run a bit lowerthan their rated specs even afterrunning <strong>for</strong> hours.The Taco engineers were kindenough to send me replacementpumps to solve my design issue. Itrequired resweating a chunk of mymanifold, and refilling my system, butit was worth it if only to reduce myelectrical load!When Naoto came by with thereplacement pump, he reviewed thedetails of my system with me. Heagreed with my assessment that thesystem efficiency could be improvedby pumping heated water throughthe heat exchanger. In the originaldesign, heat flowing up through thesecondary side of the heatexchanger would create aTotal $5,519thermosiphon effect to heat thewater stored in the tank. <strong>My</strong> feeling isthat this flow is insufficient to maximize the potentialheat transfer capability of the heat exchanger. <strong>Heat</strong>rising through the heat exchanger does not flow asrapidly as it would if pumped.We decided to add another PV panel with its ownseparate DC pump installed on the cold side of the heatexchanger. The neat thing about circulation pumps thatare direct wired to PV panels is that they only operatewhen there is sufficient sun to heat the solar collectors.We also decided to add a temperature gauge be<strong>for</strong>e theAquaStar heater, at the storage tank exit. Previously, Ihad no way of monitoring the temperature of the solarheated water emerging from the storage tank.Underpowered PV Circulating PumpsAnother issue arose when I noticed that the PV-drivencirculation pumps didn’t kick in until well after sunrise onsunny days. I e-mailed Dan Fieldman at Ivan Labs andasked what might be wrong. He explained that herecommends 20 watts of PV per pump when they areinstalled north of Jacksonville, Florida. He alsocorrected me on the orientation of my pump—the motorshould be horizontal, not vertical.Since the pumps are rated at 10 watts, <strong>Solar</strong> Markethad sold me one 10 watt <strong>Solar</strong>ex PV panel per pump. Ihave added another 20 watt <strong>Solar</strong>ex unit <strong>for</strong> a total of 40watts wired in parallel to run both my El Sid circulationpumps. This has dramatically increased my systemefficiency.42 <strong>Home</strong> <strong>Power</strong> #89 • June / July 2002