Download - All Fasteners

Download - All Fasteners

Download - All Fasteners

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

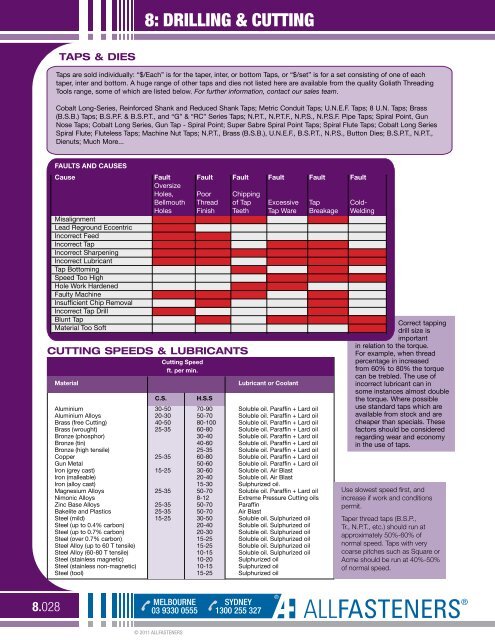

8: DRILLING & CUTTINGTAPS & DIESTaps are sold individually: “$/Each” is for the taper, inter, or bottom Taps, or “$/set” is for a set consisting of one of eachtaper, inter and bottom. A huge range of other taps and dies not listed here are available from the quality Goliath ThreadingTools range, some of which are listed below. For further information, contact our sales team.Cobalt Long-Series, Reinforced Shank and Reduced Shank Taps; Metric Conduit Taps; U.N.E.F. Taps; 8 U.N. Taps; Brass(B.S.B.) Taps; B.S.P.F. & B.S.P.T., and “G” & “RC” Series Taps; N.P.T., N.P.T.F., N.P.S., N.P.S.F. Pipe Taps; Spiral Point, GunNose Taps; Cobalt Long Series, Gun Tap - Spiral Point; Super Sabre Spiral Point Taps; Spiral Flute Taps; Cobalt Long SeriesSpiral Flute; Fluteless Taps; Machine Nut Taps; N.P.T., Brass (B.S.B.), U.N.E.F., B.S.P.T., N.P.S., Button Dies; B.S.P.T., N.P.T.,Dienuts; Much More...FAULTS AND CAUSESCause Fault Fault Fault Fault Fault FaultOversizeHoles, Poor ChippingBellmouth Thread of Tap Excessive Tap Cold-Holes Finish Teeth Tap Ware Breakage WeldingMisalignmentLead Reground EccentricIncorrect FeedIncorrect TapIncorrect SharpeningIncorrect LubricantTap BottomingSpeed Too HighHole Work HardenedFaulty MachineInsufficient Chip RemovalIncorrect Tap DrillBlunt TapMaterial Too SoftCUTTING SPEEDS & LUBRICANTSMaterialC.S.Cutting Speedft. per min.H.S.SLubricant or CoolantAluminium 30-50 70-90 Soluble oil. Paraffin + Lard oilAluminium <strong>All</strong>oys 20-30 50-70 Soluble oil. Paraffin + Lard oilBrass (free Cutting) 40-50 80-100 Soluble oil. Paraffin + Lard oilBrass (wrought) 25-35 60-80 Soluble oil. Paraffin + Lard oilBronze (phosphor) 30-40 Soluble oil. Paraffin + Lard oilBronze (tin) 40-60 Soluble oil. Paraffin + Lard oilBronze (high tensile) 25-35 Soluble oil. Paraffin + Lard oilCopper 25-35 60-80 Soluble oil. Paraffin + Lard oilGun Metal 50-60 Soluble oil. Paraffin + Lard oilIron (grey cast) 15-25 30-60 Soluble oil. Air BlastIron (malleable) 20-40 Soluble oil. Air BlastIron (alloy cast) 15-30 Sulphurized oil.Magnesium <strong>All</strong>oys 25-35 50-70 Soluble oil. Paraffin + Lard oilNimonic <strong>All</strong>oys 8-12 Extreme Pressure Cutting oilsZinc Base <strong>All</strong>oys 25-35 50-70 ParaffinBakelite and Plastics 25-35 50-70 Air BlastSteel (mild) 15-25 30-50 Soluble oil. Sulphurized oilSteel (up to 0.4% carbon) 20-40 Soluble oil. Sulphurized oilSteel (up to 0.7% carbon) 20-30 Soluble oil. Sulphurized oilSteel (over 0.7% carbon) 15-25 Soluble oil. Sulphurized oilSteel <strong>All</strong>oy (up to 60 T tensile) 15-25 Soluble oil. Sulphurized oilSteel <strong>All</strong>oy (60-80 T tensile) 10-15 Soluble oil. Sulphurized oilSteel (stainless magnetic) 10-20 Sulphurized oilSteel (stainless non-magnetic) 10-15 Sulphurized oilSteel (tool) 15-25 Sulphurized oilCorrect tappingdrill size isimportantin relation to the torque.For example, when threadpercentage in increasedfrom 60% to 80% the torquecan be trebled. The use ofincorrect lubricant can insome instances almost doublethe torque. Where possibleuse standard taps which areavailable from stock and arecheaper than specials. Thesefactors should be consideredregarding wear and economyin the use of taps.Use slowest speed first, andincrease if work and conditionspermit.Taper thread taps (B.S.P.,Tr., N.P.T., etc.) should run atapproximately 50%-60% ofnormal speed. Taps with verycoarse pitches such as Square orAcme should be run at 40%-50%of normal speed.8.028MELBOURNE03 9330 0555SYDNEY1300 255 327© 2011 ALLFASTENERS