RTM 270/B - Berco S.p.A

RTM 270/B - Berco S.p.A

RTM 270/B - Berco S.p.A

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

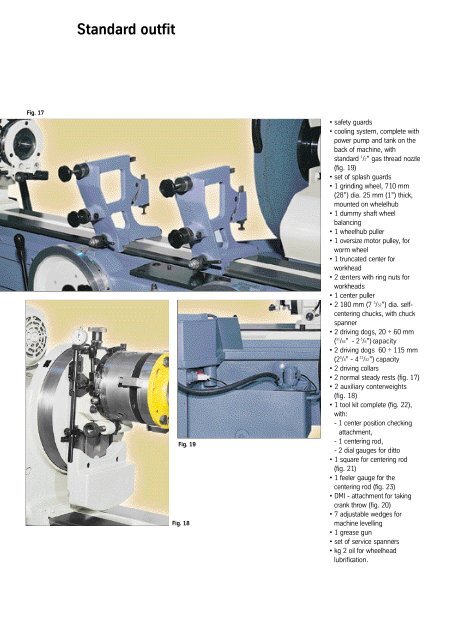

Standard outfitFig. 17Fig. 19Fig. 18• safety guard s• cooling system, complete withp ower pump and tank on theback of machine, withs t a n d a rd 1 /2” gas thread nozzle(fig. 19)• set of splash guard s• 1 grinding wheel, 710 mm(28”) dia. 25 mm (1”) thick,mounted on whelelhub• 1 dummy shaft wheelb a l a n c i n g• 1 wheelhub puller• 1 ove rsize motor pulley, fo rworm wheel• 1 truncated center fo rwo r k h e a d• 2 ce n t e rs with ring nuts fo rworkheads• 1 center puller• 2 180 mm (7 3 /3 2”) dia. selfcenteringchucks, with chucks p a n n e r• 2 driving dogs, 20 ÷ 60 mm( 3 1 /6 4” - 2 3 /8”) ca p a c i t y• 2 driving dogs 60 ÷ 115 mm( 2 3 /8” - 4 1 2 /3 2”) ca p a c i t y• 2 driving collars• 2 normal steady rests (fig. 17)• 2 auxiliary conterweights(fig. 18)• 1 tool kit complete (fig. 22),w i t h :- 1 center position checkinga tt a c h m e n t ,- 1 centering rod,- 2 dial gauges for ditt o• 1 square for centering rod(fig. 21)• 1 feeler gauge for thecentering rod (fig. 23)• DMI - attachment for takingc rank throw (fig. 20)• 7 adjustable wedges fo rmachine levelling• 1 grease gun• set of serv i ce spanners• kg 2 oil for wheelheadl u b r i f i ca t i o n .