RTM 270/B - Berco S.p.A

RTM 270/B - Berco S.p.A

RTM 270/B - Berco S.p.A

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

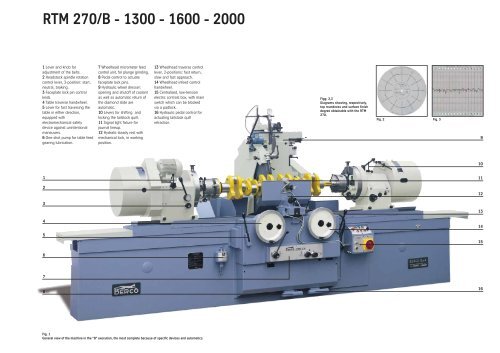

<strong>RTM</strong> <strong>270</strong>/B - 1300 - 1600 - 20001 Lever and knob foradjustment of the belts.2 Headstock spindle rotationcontrol lever, 3-position: start,neutral, braking.3 Faceplate lock pin controlknob.4 Table traverse handwheel.5 Lever for fast traversing thetable in either direction,equipped withelectromechanical safetydevice against unintentionalmaneuvers.6 One-shot pump for table feedgearing lubrication.7 Wheelhead micrometer feedcontrol unit, for plunge grinding.8 Pedal control to actuatefaceplate lock pins.9 Hydraulic wheel dresser:opening and shutoff of coolantas well as automatic return ofthe diamond slide areautomatic.10 Levers for shifting andlocking the tailstock quill.11 Signal light fixture forjournal lineup.12 Hydralic steady rest withmechanical lock, in workingposition.13 Wheelhead traverse controllever, 2-positions: fast return,slow and fast approach.14 Wheelhead infeed controlhandwheel.15 Centralized, low-tensionelectric controls box, with mainswitch which can be blockedvia a padlock.16 Hydraulic pedal control foractuating tailstock quillretraction.Figg. 2,3Diagrams showing, respectively,top roundness and surface finishdegree obtainable with the <strong>RTM</strong><strong>270</strong>.Fig. 2 Fig. 391011121231341451567816Fig. 1General view of the machine in the “B” execution, the most complete because of specific devices and automatics.