RTM 270/B - Berco S.p.A

RTM 270/B - Berco S.p.A

RTM 270/B - Berco S.p.A

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

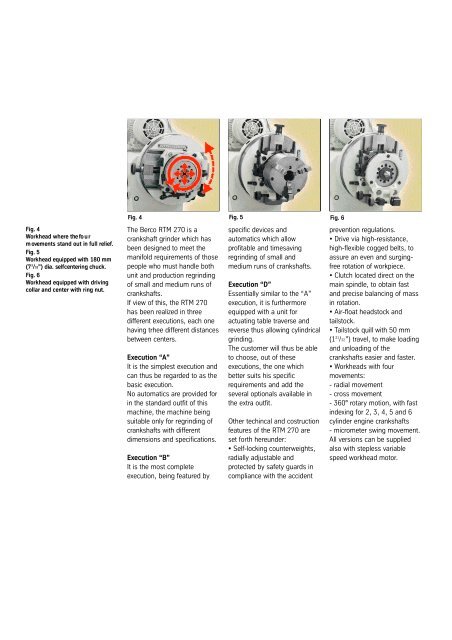

Fig. 4Workhead where the fo u rm ovements stand out in full re l i e f .Fig. 5Workhead equipped with 180 mm( 7 3 /3 2”) dia. selfcentering chuck.Fig. 6Workhead equipped with drivingcollar and center with ring nut.Fig. 4 Fig. 5 Fig. 6The <strong>Berco</strong> <strong>RTM</strong> <strong>270</strong> is acrankshaft grinder which hasbeen designed to meet themanifold requirements of thosepeople who must handle bothunit and production regrindingof small and medium runs ofcrankshafts.If view of this, the <strong>RTM</strong> <strong>270</strong>has been realized in threedifferent executions, each onehaving trhee different distancesbetween centers.Execution “A”It is the simplest execution andcan thus be regarded to as thebasic execution.No automatics are provided forin the standard outfit of thismachine, the machine beingsuitable only for regrinding ofcrankshafts with differentdimensions and specifications.Execution “B”It is the most completeexecution, being featured byspecific devices andautomatics which allowprofitable and timesavingregrinding of small andmedium runs of crankshafts.Execution “D”Essentially similar to the “A”execution, it is furthermoreequipped with a unit foractuating table traverse andreverse thus allowing cylindricalgrinding.The customer will thus be ableto choose, out of theseexecutions, the one whichbetter suits his specificrequirements and add theseveral optionals available inthe extra outfit.Other techincal and costructionfeatures of the <strong>RTM</strong> <strong>270</strong> areset forth hereunder:• Self-locking counterweights,radially adjustable andprotected by safety guards incompliance with the accidentprevention regulations.• Drive via high-resistance,high-flexible cogged belts, toassure an even and surgingfreerotation of workpiece.• Clutch located direct on themain spindle, to obtain fastand precise balancing of massin rotation.• Air-float headstock andtailstock.• Tailstock quill with 50 mm(1 31 /32”) travel, to make loadingand unloading of thecrankshafts easier and faster.• Workheads with fourmovements:- radial movement- cross movement- 360° rotary motion, with fastindexing for 2, 3, 4, 5 and 6cylinder engine crankshafts- micrometer swing movement.All versions can be suppliedalso with stepless variablespeed workhead motor.