RTM 270/B - Berco S.p.A

RTM 270/B - Berco S.p.A

RTM 270/B - Berco S.p.A

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

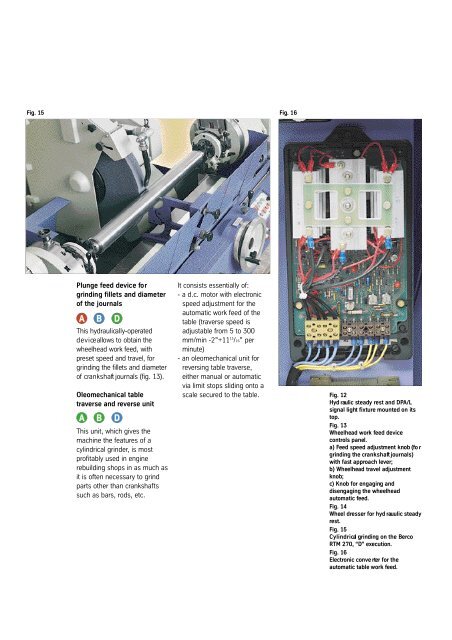

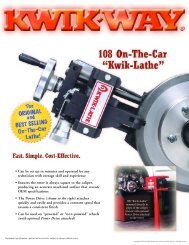

Fig. 15 Fig. 16Plunge feed device fo rgrinding fillets and diameterof the journalsA B DThis hyd ra u l i ca l l y- o p e ra t e dd e v i ce allows to obtain thewheelhead work feed, withp reset speed and travel, fo rgrinding the fillets and diameterof cra n k s h a ft journals (fig. 13).Oleomechanical tabletraverse and reverse unitA B DThis unit, which gives themachine the features of acylindrical grinder, is mostprofitably used in enginerebuilding shops in as much asit is often necessary to grindparts other than crankshaftssuch as bars, rods, etc.It consists essentially of:- a d.c. motor with electronicspeed adjustment for theautomatic work feed of thetable (traverse speed isadjustable from 5 to 300mm/min -2”+11 13 /16” perminute)- an oleomechanical unit forreversing table traverse,either manual or automaticvia limit stops sliding onto ascale secured to the table.Fig. 12H yd raulic steady rest and DPA / Lsignal light fixture mounted on itst o p .Fig. 13Wheelhead work feed devicec o n t rols panel.a) Feed speed adjustment knob (fo rgrinding the cra n k s h a ft journals)with fast approach lever;b) Wheelhead travel adjustmentk n o b ;c) Knob for engaging anddisengaging the wheelheadautomatic fe e d .Fig. 14Wheel dresser for hyd rauulic steadyre s t .Fig. 15C y l i n d r i cal grinding on the Berc o<strong>RTM</strong> <strong>270</strong>, “D” exe c u t i o n .Fig. 16E l e ct ronic conve rter for theautomatic table work fe e d .