Issue 60 - Tornos

Issue 60 - Tornos

Issue 60 - Tornos

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

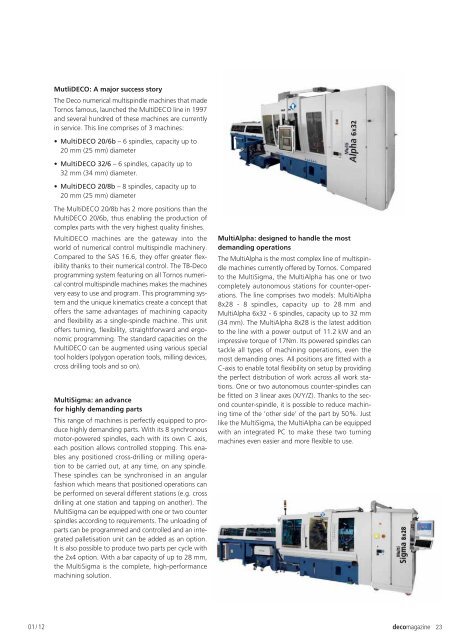

MutliDECO : A major success storyThe Deco numerical multispindle machines that made<strong>Tornos</strong> famous, launched the MultiDECO line in 1997and several hundred of these machines are currentlyin service. This line comprises of 3 machines : MultiDECO 20 / 6b – 6 spindles, capacity up to20 mm (25 mm) diameter MultiDECO 32/6 – 6 spindles, capacity up to32 mm (34 mm) diameter. MultiDECO 20/8b – 8 spindles, capacity up to20 mm (25 mm) diameterThe MultiDECO 20/8b has 2 more positions than theMultiDECO 20/6b, thus enabling the production ofcomplex parts with the very highest quality finishes.MultiDECO machines are the gateway into theworld of numerical control multispindle machinery.Compared to the SAS 16.6, they offer greater flexibilitythanks to their numerical control. The TB-Decoprogramming system featuring on all <strong>Tornos</strong> numericalcontrol multispindle machines makes the machinesvery easy to use and program. This programming systemand the unique kinematics create a concept thatoffers the same advantages of machining capacityand flexibility as a single-spindle machine. This unitoffers turning, flexibility, straightforward and ergonomicprogramming. The standard capacities on theMultiDECO can be augmented using various specialtool holders (polygon operation tools, milling devices,cross drilling tools and so on).MultiSigma : an advancefor highly demanding partsThis range of machines is perfectly equipped to producehighly demanding parts. With its 8 synchronousmotor-powered spindles, each with its own C axis,each position allows controlled stopping. This enablesany positioned cross-drilling or milling operationto be carried out, at any time, on any spindle.These spindles can be synchronised in an angularfashion which means that positioned operations canbe performed on several different stations (e.g. crossdrilling at one station and tapping on another). TheMultiSigma can be equipped with one or two counterspindles according to requirements. The unloading ofparts can be programmed and controlled and an integratedpalletisation unit can be added as an option.It is also possible to produce two parts per cycle withthe 2x4 option. With a bar capacity of up to 28 mm,the MultiSigma is the complete, high-performancemachining solution.MultiAlpha : designed to handle the mostdemanding operationsThe MultiAlpha is the most complex line of multispindlemachines currently offered by <strong>Tornos</strong>. Comparedto the MultiSigma, the MultiAlpha has one or twocompletely autonomous stations for counter-operations.The line comprises two models : MultiAlpha8x28 - 8 spindles, capacity up to 28 mm andMultiAlpha 6x32 - 6 spindles, capacity up to 32 mm(34 mm). The MultiAlpha 8x28 is the latest additionto the line with a power output of 11.2 kW and animpressive torque of 17Nm. Its powered spindles cantackle all types of machining operations, even themost demanding ones. All positions are fitted with aC-axis to enable total flexibility on setup by providingthe perfect distribution of work across all work stations.One or two autonomous counter-spindles canbe fitted on 3 linear axes (X/ Y / Z). Thanks to the secondcounter-spindle, it is possible to reduce machiningtime of the ‘other side’ of the part by 50 %. Justlike the MultiSigma, the MultiAlpha can be equippedwith an integrated PC to make these two turningmachines even easier and more flexible to use.01 / 12 decomagazine 23