2006 PRODUCT CATALOG

2006 PRODUCT CATALOG

2006 PRODUCT CATALOG

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

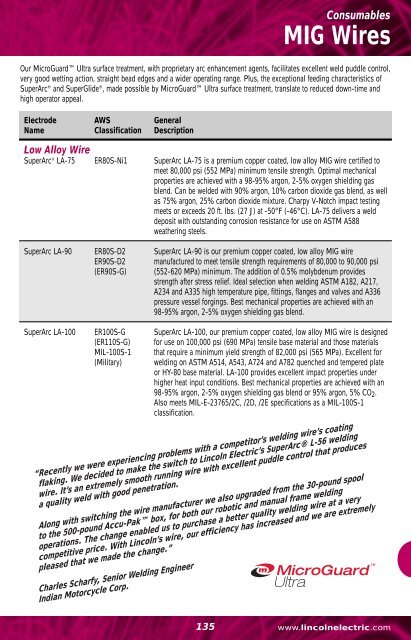

Consumables<br />

MIG Wires<br />

Our MicroGuard Ultra surface treatment, with proprietary arc enhancement agents, facilitates excellent weld puddle control,<br />

very good wetting action, straight bead edges and a wider operating range. Plus, the exceptional feeding characteristics of<br />

SuperArc ® and SuperGlide ® , made possible by MicroGuard Ultra surface treatment, translate to reduced down-time and<br />

high operator appeal.<br />

Electrode AWS General<br />

Name Classification Description<br />

Low Alloy Wire<br />

SuperArc ® LA-75 ER80S-Ni1 SuperArc LA-75 is a premium copper coated, low alloy MIG wire certified to<br />

meet 80,000 psi (552 MPa) minimum tensile strength. Optimal mechanical<br />

properties are achieved with a 98-95% argon, 2-5% oxygen shielding gas<br />

blend. Can be welded with 90% argon, 10% carbon dioxide gas blend, as well<br />

as 75% argon, 25% carbon dioxide mixture. Charpy V-Notch impact testing<br />

meets or exceeds 20 ft. lbs. (27 J) at -50°F (-46°C). LA-75 delivers a weld<br />

deposit with outstanding corrosion resistance for use on ASTM A588<br />

weathering steels.<br />

SuperArc LA-90 ER80S-D2 SuperArc LA-90 is our premium copper coated, low alloy MIG wire<br />

ER90S-D2 manufactured to meet tensile strength requirements of 80,000 to 90,000 psi<br />

(ER90S-G) (552-620 MPa) minimum. The addition of 0.5% molybdenum provides<br />

strength after stress relief. Ideal selection when welding ASTM A182, A217,<br />

A234 and A335 high temperature pipe, fittings, flanges and valves and A336<br />

pressure vessel forgings. Best mechanical properties are achieved with an<br />

98-95% argon, 2-5% oxygen shielding gas blend.<br />

SuperArc LA-100 ER100S-G SuperArc LA-100, our premium copper coated, low alloy MIG wire is designed<br />

(ER110S-G) for use on 100,000 psi (690 MPa) tensile base material and those materials<br />

MIL-100S-1 that require a minimum yield strength of 82,000 psi (565 MPa). Excellent for<br />

(Military) welding on ASTM A514, A543, A724 and A782 quenched and tempered plate<br />

or HY-80 base material. LA-100 provides excellent impact properties under<br />

higher heat input conditions. Best mechanical properties are achieved with an<br />

98-95% argon, 2-5% oxygen shielding gas blend or 95% argon, 5% CO2.<br />

Also meets MIL-E-23765/2C, /2D, /2E specifications as a MIL-100S-1<br />

classification.<br />

“Recently we were experiencing problems with a competitor’s welding wire’s coating<br />

flaking. We decided to make the switch to Lincoln Electric’s SuperArc® L-56 welding<br />

wire. It’s an extremely smooth running wire with excellent puddle control that produces<br />

a quality weld with good penetration.<br />

Along with switching the wire manufacturer we also upgraded from the 30-pound spool<br />

to the 500-pound Accu-Pak box, for both our robotic and manual frame welding<br />

operations. The change enabled us to purchase a better quality welding wire at a very<br />

competitive price. With Lincoln’s wire, our efficiency has increased and we are extremely<br />

pleased that we made the change.”<br />

Charles Scharfy, Senior Welding Engineer<br />

Indian Motorcycle Corp.<br />

135 www.lincolnelectric.com