2006 PRODUCT CATALOG

2006 PRODUCT CATALOG

2006 PRODUCT CATALOG

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

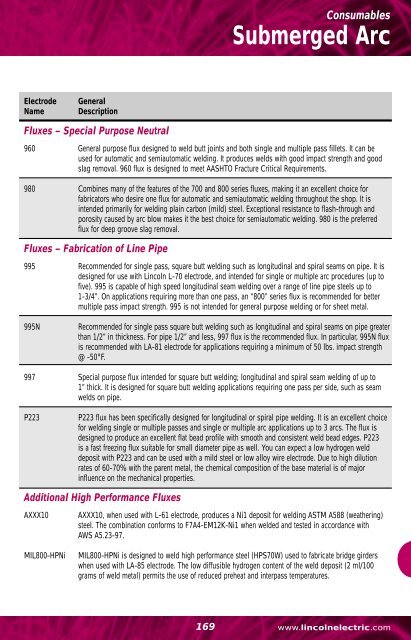

Electrode General<br />

Name Description<br />

Fluxes – Special Purpose Neutral<br />

Consumables<br />

Submerged Arc<br />

960 General purpose flux designed to weld butt joints and both single and multiple pass fillets. It can be<br />

used for automatic and semiautomatic welding. It produces welds with good impact strength and good<br />

slag removal. 960 flux is designed to meet AASHTO Fracture Critical Requirements.<br />

980 Combines many of the features of the 700 and 800 series fluxes, making it an excellent choice for<br />

fabricators who desire one flux for automatic and semiautomatic welding throughout the shop. It is<br />

intended primarily for welding plain carbon (mild) steel. Exceptional resistance to flash-through and<br />

porosity caused by arc blow makes it the best choice for semiautomatic welding. 980 is the preferred<br />

flux for deep groove slag removal.<br />

Fluxes – Fabrication of Line Pipe<br />

995 Recommended for single pass, square butt welding such as longitudinal and spiral seams on pipe. It is<br />

designed for use with Lincoln L-70 electrode, and intended for single or multiple arc procedures (up to<br />

five). 995 is capable of high speed longitudinal seam welding over a range of line pipe steels up to<br />

1-3/4”. On applications requiring more than one pass, an “800” series flux is recommended for better<br />

multiple pass impact strength. 995 is not intended for general purpose welding or for sheet metal.<br />

995N Recommended for single pass square butt welding such as longitudinal and spiral seams on pipe greater<br />

than 1/2” in thickness. For pipe 1/2” and less, 997 flux is the recommended flux. In particular, 995N flux<br />

is recommended with LA-81 electrode for applications requiring a minimum of 50 lbs. impact strength<br />

@ -50°F.<br />

997 Special purpose flux intended for square butt welding; longitudinal and spiral seam welding of up to<br />

1” thick. It is designed for square butt welding applications requiring one pass per side, such as seam<br />

welds on pipe.<br />

P223 P223 flux has been specifically designed for longitudinal or spiral pipe welding. It is an excellent choice<br />

for welding single or multiple passes and single or multiple arc applications up to 3 arcs. The flux is<br />

designed to produce an excellent flat bead profile with smooth and consistent weld bead edges. P223<br />

is a fast freezing flux suitable for small diameter pipe as well. You can expect a low hydrogen weld<br />

deposit with P223 and can be used with a mild steel or low alloy wire electrode. Due to high dilution<br />

rates of 60-70% with the parent metal, the chemical composition of the base material is of major<br />

influence on the mechanical properties.<br />

Additional High Performance Fluxes<br />

AXXX10 AXXX10, when used with L-61 electrode, produces a Ni1 deposit for welding ASTM A588 (weathering)<br />

steel. The combination conforms to F7A4-EM12K-Ni1 when welded and tested in accordance with<br />

AWS A5.23-97.<br />

MIL800-HPNi MIL800-HPNi is designed to weld high performance steel (HPS70W) used to fabricate bridge girders<br />

when used with LA-85 electrode. The low diffusible hydrogen content of the weld deposit (2 ml/100<br />

grams of weld metal) permits the use of reduced preheat and interpass temperatures.<br />

169 www.lincolnelectric.com