2006 PRODUCT CATALOG

2006 PRODUCT CATALOG

2006 PRODUCT CATALOG

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

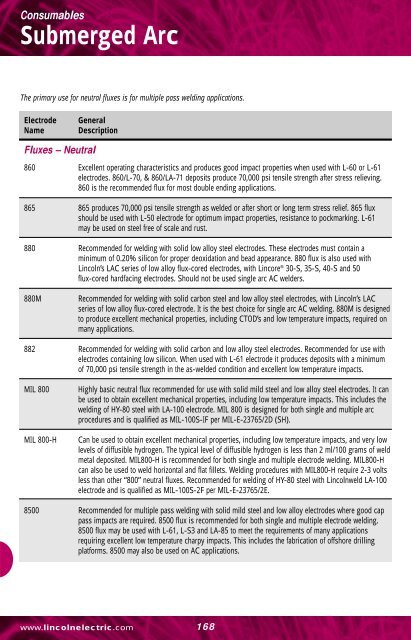

Consumables<br />

Submerged Arc<br />

The primary use for neutral fluxes is for multiple pass welding applications.<br />

Electrode General<br />

Name Description<br />

Fluxes – Neutral<br />

860 Excellent operating characteristics and produces good impact properties when used with L-60 or L-61<br />

electrodes. 860/L-70, & 860/LA-71 deposits produce 70,000 psi tensile strength after stress relieving.<br />

860 is the recommended flux for most double ending applications.<br />

865 865 produces 70,000 psi tensile strength as welded or after short or long term stress relief. 865 flux<br />

should be used with L-50 electrode for optimum impact properties, resistance to pockmarking. L-61<br />

may be used on steel free of scale and rust.<br />

880 Recommended for welding with solid low alloy steel electrodes. These electrodes must contain a<br />

minimum of 0.20% silicon for proper deoxidation and bead appearance. 880 flux is also used with<br />

Lincoln’s LAC series of low alloy flux-cored electrodes, with Lincore ® 30-S, 35-S, 40-S and 50<br />

flux-cored hardfacing electrodes. Should not be used single arc AC welders.<br />

880M Recommended for welding with solid carbon steel and low alloy steel electrodes, with Lincoln’s LAC<br />

series of low alloy flux-cored electrode. It is the best choice for single arc AC welding. 880M is designed<br />

to produce excellent mechanical properties, including CTOD’s and low temperature impacts, required on<br />

many applications.<br />

882 Recommended for welding with solid carbon and low alloy steel electrodes. Recommended for use with<br />

electrodes containing low silicon. When used with L-61 electrode it produces deposits with a minimum<br />

of 70,000 psi tensile strength in the as-welded condition and excellent low temperature impacts.<br />

MIL 800 Highly basic neutral flux recommended for use with solid mild steel and low alloy steel electrodes. It can<br />

be used to obtain excellent mechanical properties, including low temperature impacts. This includes the<br />

welding of HY-80 steel with LA-100 electrode. MIL 800 is designed for both single and multiple arc<br />

procedures and is qualified as MIL-100S-IF per MIL-E-23765/2D (SH).<br />

MIL 800-H Can be used to obtain excellent mechanical properties, including low temperature impacts, and very low<br />

levels of diffusible hydrogen. The typical level of diffusible hydrogen is less than 2 ml/100 grams of weld<br />

metal deposited. MIL800-H is recommended for both single and multiple electrode welding. MIL800-H<br />

can also be used to weld horizontal and flat fillets. Welding procedures with MIL800-H require 2-3 volts<br />

less than other “800” neutral fluxes. Recommended for welding of HY-80 steel with Lincolnweld LA-100<br />

electrode and is qualified as MIL-100S-2F per MIL-E-23765/2E.<br />

8500 Recommended for multiple pass welding with solid mild steel and low alloy electrodes where good cap<br />

pass impacts are required. 8500 flux is recommended for both single and multiple electrode welding.<br />

8500 flux may be used with L-61, L-S3 and LA-85 to meet the requirements of many applications<br />

requiring excellent low temperature charpy impacts. This includes the fabrication of offshore drilling<br />

platforms. 8500 may also be used on AC applications.<br />

www.lincolnelectric.com<br />

168