Brochure: HUBER Belt Screen EscaMax

Brochure: HUBER Belt Screen EscaMax

Brochure: HUBER Belt Screen EscaMax

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

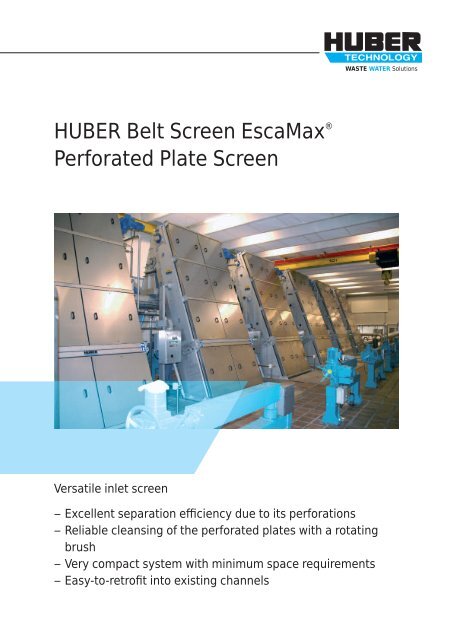

WASTE WATER Solutions<strong>HUBER</strong> <strong>Belt</strong> <strong>Screen</strong> <strong>EscaMax</strong> ®Perforated Plate <strong>Screen</strong>Versatile inlet screen– Excellent separation efficiency due to its perforations– Reliable cleansing of the perforated plates with a rotatingbrush– Very compact system with minimum space requirements– Easy-to-retrofit into existing channels

➤ Design and functionThe <strong>HUBER</strong> <strong>Belt</strong> <strong>Screen</strong> <strong>EscaMax</strong>® complements thewell-known <strong>HUBER</strong> program for municipal and industrialwaste water screening, as it is particularly well suited insituations where excellent separation efficiency isrequired in deep channels with high water levels.Perforated screening elements provide superiorseparation efficiency in comparison with slit screeningelements. It has been determined that two-dimensionalperforations are better than one-dimensional slits.Formation of screenings rolls is prevented by rake barsextending over the full width of the screen in combinationwith the screen's installation angle. Even cans and bottlesare lifted by these rakes.Each end of the perforated plates is connected with adrive chain. Each chain is driven by a sprocket on acommon shaft and a flange mounted gear motor.At their upper turning point the perforated plates arecontinuously cleaned by a fast counterrotating brushwhich increases the cleaning energy and thus signifi -cantly improves the cleaning efficiency. Cleansing issupported by an integrated spray bar.The sturdy <strong>HUBER</strong> <strong>Belt</strong> <strong>Screen</strong> <strong>EscaMax</strong>® is able toreliably cope with even high amounts of gravel and grit.The two-dimensional screening elements preventespecially long fibres from passing through the screenand achieve thus the maximum separation efficiency.Flow diagram of a <strong>HUBER</strong> <strong>Belt</strong> <strong>Screen</strong> <strong>EscaMax</strong>®

WASTE WATER Solutions➤ The challenge – Our solutionWe have been challenged to provide screens combiningever increasing separation efficiency with operationalreliability. The <strong>EscaMax</strong>® <strong>Screen</strong> is our answer to thischallenge.State-of-the-art design of a perforated plate screen thatguarantees the highest efficiency, lowmaintenance and long life required attention to everydetail.Our Perforated Plate <strong>Screen</strong> <strong>EscaMax</strong>® sets newstandards, due to its innovative features.➤ Functional details of the <strong>HUBER</strong> <strong>Belt</strong> <strong>Screen</strong> <strong>EscaMax</strong>®Innovative cleaning system with a rotating brushThe distinctive feature of the innovative perforatedplate cleaning system compared to other state-of-theartsystems is its significantly improved efficiency due toits special arrangement and counterrotating brush.Other systems require an additional scraper roller toremove screenings from the trough edge.A counterrotating brush eliminates this problem so thatno additional scraper roller is required for trough edgecleaning.Wear-resistant plastic elements ensure proper sealingbetween the travelling screening elements andthe frame whilst the perforated plates are moving. Theconnection between the plastic and screening elementsis designed to allow quick and easy replacement.The submerged chain wheel bearing consists of ahighly wear-resistant and maintenance-free ceramicbearing which has proven its reliability for years in ourgrit washing plants.The drive chain is made of hardened wear-resistant steel.The chain and chain wheels are electrogalvanised andyellow chromated for durable corrosion protection. Asan option, the chains and chain wheels are available instainless steel.counterrotatingbrush roller

WASTE WATER Solutions➤ The benefits of the <strong>EscaMax</strong>® <strong>Screen</strong> at a glance➤ Excellent separation efficiency due travellingperforated plates➤ Reliable cleansing of the perforated plates with arotating brush➤ No scraper roller for trough edge cleaning required➤ All submerged bearings are wear-resistant ceramicbearings.➤ Compact design with a low installation height aboveground level➤ Completely odour-encased screen with easy toremove covers➤ Easy-to-retrofit into existing channels, installationwithout channel recesses possible➤ The screen consists of a self-supporting foldedstainless steel profile so that it can easily be liftedout of the channel.➤ Not hindered by gravel or grit➤ Simple and easy-to-access chain tensioning unit➤ All machine components in contact with the mediumare made of stainless steel and acid treated in apickling bath (except chains, drives, bearings). As anoption, the chains and chain wheels are available instainless steel.➤ Installation examplesRear view of the <strong>HUBER</strong> <strong>Belt</strong> <strong>Screen</strong> <strong>EscaMax</strong>® with sub -sequent launder channel for wear-free screenings transportFully enclosed, odour-free screen with easy to removecovers➤ <strong>Screen</strong> sizesChannel width:Discharge height:up to 3000 mmup to 9500 mmPerforations:≥ 3.5 mmInstallation angle: 45° - 70°<strong>HUBER</strong> SEIndustriepark Erasbach A1 · D-92334 BerchingPhone: + 49 - 84 62 - 201 - 0 · Fax: + 49 - 84 62 - 201 - 810info@huber.de · Internet: www.huber.deSubject to technical modification0,0 / 9 – 12.2012 – 10.2003<strong>HUBER</strong> <strong>Belt</strong> <strong>Screen</strong> <strong>EscaMax</strong>®Perforated Plate <strong>Screen</strong>