THE YEAR-BOOK OF THE COKE OVEN - Coke Oven Managers ...

THE YEAR-BOOK OF THE COKE OVEN - Coke Oven Managers ...

THE YEAR-BOOK OF THE COKE OVEN - Coke Oven Managers ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

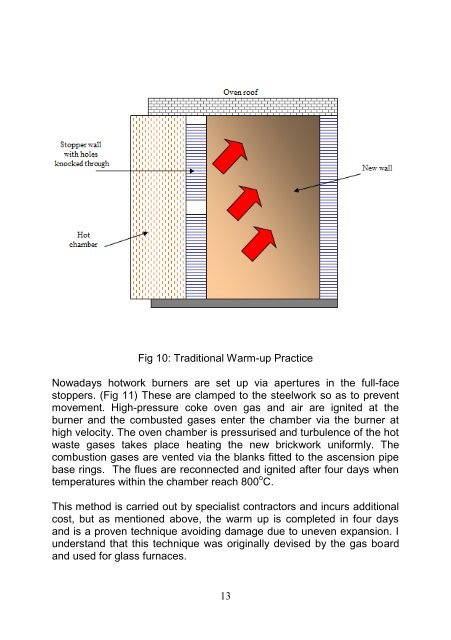

Fig 10: Traditional Warm-up PracticeNowadays hotwork burners are set up via apertures in the full-facestoppers. (Fig 11) These are clamped to the steelwork so as to preventmovement. High-pressure coke oven gas and air are ignited at theburner and the combusted gases enter the chamber via the burner athigh velocity. The oven chamber is pressurised and turbulence of the hotwaste gases takes place heating the new brickwork uniformly. Thecombustion gases are vented via the blanks fitted to the ascension pipebase rings. The flues are reconnected and ignited after four days whentemperatures within the chamber reach 800 o C.This method is carried out by specialist contractors and incurs additionalcost, but as mentioned above, the warm up is completed in four daysand is a proven technique avoiding damage due to uneven expansion. Iunderstand that this technique was originally devised by the gas boardand used for glass furnaces.13