THE YEAR-BOOK OF THE COKE OVEN - Coke Oven Managers ...

THE YEAR-BOOK OF THE COKE OVEN - Coke Oven Managers ...

THE YEAR-BOOK OF THE COKE OVEN - Coke Oven Managers ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

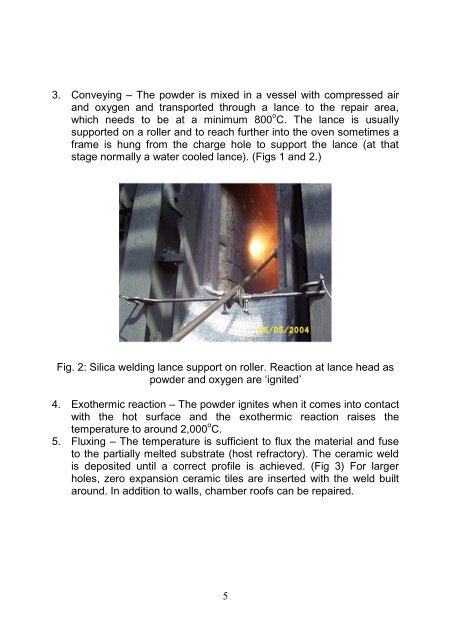

3. Conveying – The powder is mixed in a vessel with compressed airand oxygen and transported through a lance to the repair area,which needs to be at a minimum 800 o C. The lance is usuallysupported on a roller and to reach further into the oven sometimes aframe is hung from the charge hole to support the lance (at thatstage normally a water cooled lance). (Figs 1 and 2.)Fig. 2: Silica welding lance support on roller. Reaction at lance head aspowder and oxygen are ‘ignited’4. Exothermic reaction – The powder ignites when it comes into contactwith the hot surface and the exothermic reaction raises thetemperature to around 2,000 o C.5. Fluxing – The temperature is sufficient to flux the material and fuseto the partially melted substrate (host refractory). The ceramic weldis deposited until a correct profile is achieved. (Fig 3) For largerholes, zero expansion ceramic tiles are inserted with the weld builtaround. In addition to walls, chamber roofs can be repaired.5