THE YEAR-BOOK OF THE COKE OVEN - Coke Oven Managers ...

THE YEAR-BOOK OF THE COKE OVEN - Coke Oven Managers ...

THE YEAR-BOOK OF THE COKE OVEN - Coke Oven Managers ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

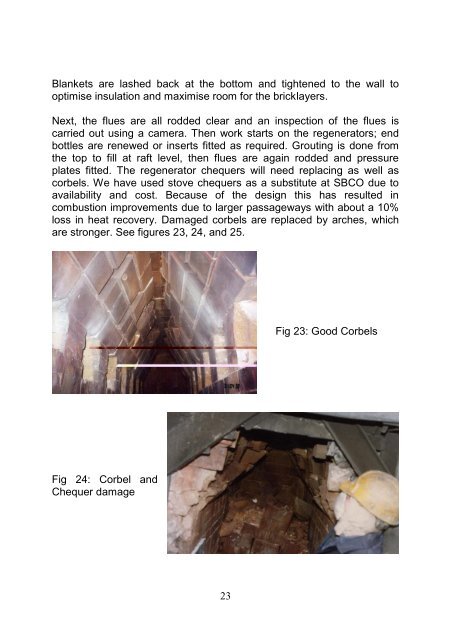

Blankets are lashed back at the bottom and tightened to the wall tooptimise insulation and maximise room for the bricklayers.Next, the flues are all rodded clear and an inspection of the flues iscarried out using a camera. Then work starts on the regenerators; endbottles are renewed or inserts fitted as required. Grouting is done fromthe top to fill at raft level, then flues are again rodded and pressureplates fitted. The regenerator chequers will need replacing as well ascorbels. We have used stove chequers as a substitute at SBCO due toavailability and cost. Because of the design this has resulted incombustion improvements due to larger passageways with about a 10%loss in heat recovery. Damaged corbels are replaced by arches, whichare stronger. See figures 23, 24, and 25.Fig 23: Good CorbelsFig 24: Corbel andChequer damage23