THE YEAR-BOOK OF THE COKE OVEN - Coke Oven Managers ...

THE YEAR-BOOK OF THE COKE OVEN - Coke Oven Managers ...

THE YEAR-BOOK OF THE COKE OVEN - Coke Oven Managers ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

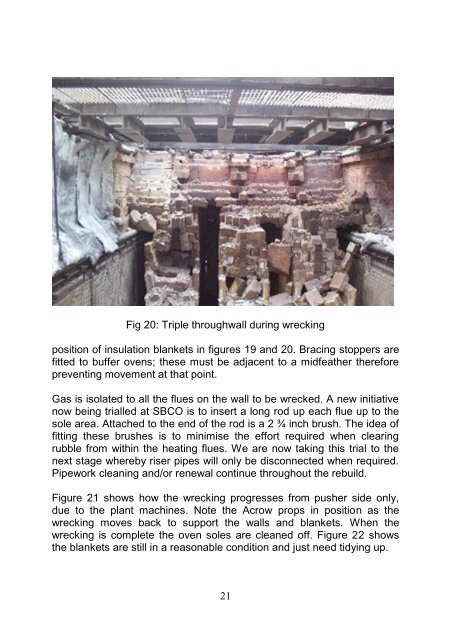

Fig 20: Triple throughwall during wreckingposition of insulation blankets in figures 19 and 20. Bracing stoppers arefitted to buffer ovens; these must be adjacent to a midfeather thereforepreventing movement at that point.Gas is isolated to all the flues on the wall to be wrecked. A new initiativenow being trialled at SBCO is to insert a long rod up each flue up to thesole area. Attached to the end of the rod is a 2 ¾ inch brush. The idea offitting these brushes is to minimise the effort required when clearingrubble from within the heating flues. We are now taking this trial to thenext stage whereby riser pipes will only be disconnected when required.Pipework cleaning and/or renewal continue throughout the rebuild.Figure 21 shows how the wrecking progresses from pusher side only,due to the plant machines. Note the Acrow props in position as thewrecking moves back to support the walls and blankets. When thewrecking is complete the oven soles are cleaned off. Figure 22 showsthe blankets are still in a reasonable condition and just need tidying up.21