THE YEAR-BOOK OF THE COKE OVEN - Coke Oven Managers ...

THE YEAR-BOOK OF THE COKE OVEN - Coke Oven Managers ...

THE YEAR-BOOK OF THE COKE OVEN - Coke Oven Managers ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

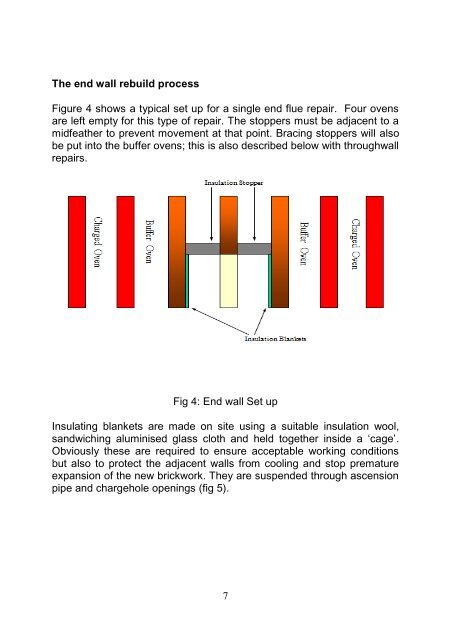

The end wall rebuild processFigure 4 shows a typical set up for a single end flue repair. Four ovensare left empty for this type of repair. The stoppers must be adjacent to amidfeather to prevent movement at that point. Bracing stoppers will alsobe put into the buffer ovens; this is also described below with throughwallrepairs.Fig 4: End wall Set upInsulating blankets are made on site using a suitable insulation wool,sandwiching aluminised glass cloth and held together inside a ‘cage’.Obviously these are required to ensure acceptable working conditionsbut also to protect the adjacent walls from cooling and stop prematureexpansion of the new brickwork. They are suspended through ascensionpipe and chargehole openings (fig 5).7