Ammended NI 43-101 Technical Report on the Biely ... - EMED Mining

Ammended NI 43-101 Technical Report on the Biely ... - EMED Mining

Ammended NI 43-101 Technical Report on the Biely ... - EMED Mining

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

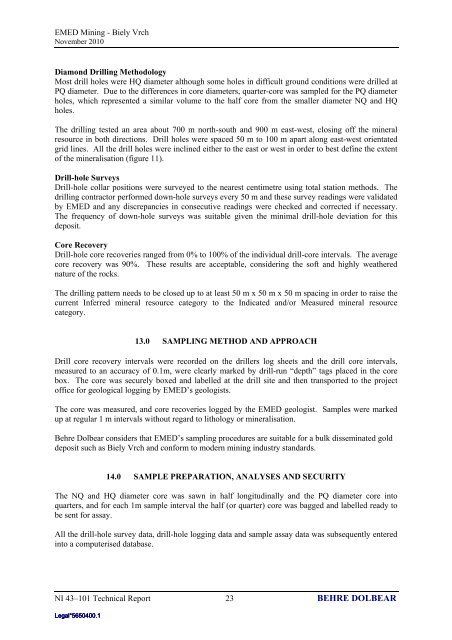

<strong>EMED</strong> <strong>Mining</strong> - <strong>Biely</strong> VrchNovember 2010Diam<strong>on</strong>d Drilling MethodologyMost drill holes were HQ diameter although some holes in difficult ground c<strong>on</strong>diti<strong>on</strong>s were drilled atPQ diameter. Due to <strong>the</strong> differences in core diameters, quarter-core was sampled for <strong>the</strong> PQ diameterholes, which represented a similar volume to <strong>the</strong> half core from <strong>the</strong> smaller diameter NQ and HQholes.The drilling tested an area about 700 m north-south and 900 m east-west, closing off <strong>the</strong> mineralresource in both directi<strong>on</strong>s. Drill holes were spaced 50 m to 100 m apart al<strong>on</strong>g east-west orientatedgrid lines. All <strong>the</strong> drill holes were inclined ei<strong>the</strong>r to <strong>the</strong> east or west in order to best define <strong>the</strong> extentof <strong>the</strong> mineralisati<strong>on</strong> (figure 11).Drill-hole SurveysDrill-hole collar positi<strong>on</strong>s were surveyed to <strong>the</strong> nearest centimetre using total stati<strong>on</strong> methods. Thedrilling c<strong>on</strong>tractor performed down-hole surveys every 50 m and <strong>the</strong>se survey readings were validatedby <strong>EMED</strong> and any discrepancies in c<strong>on</strong>secutive readings were checked and corrected if necessary.The frequency of down-hole surveys was suitable given <strong>the</strong> minimal drill-hole deviati<strong>on</strong> for thisdeposit.Core RecoveryDrill-hole core recoveries ranged from 0% to 100% of <strong>the</strong> individual drill-core intervals. The averagecore recovery was 90%. These results are acceptable, c<strong>on</strong>sidering <strong>the</strong> soft and highly wea<strong>the</strong>rednature of <strong>the</strong> rocks.The drilling pattern needs to be closed up to at least 50 m x 50 m x 50 m spacing in order to raise <strong>the</strong>current Inferred mineral resource category to <strong>the</strong> Indicated and/or Measured mineral resourcecategory.13.0 SAMPLING METHOD AND APPROACHDrill core recovery intervals were recorded <strong>on</strong> <strong>the</strong> drillers log sheets and <strong>the</strong> drill core intervals,measured to an accuracy of 0.1m, were clearly marked by drill-run “depth” tags placed in <strong>the</strong> corebox. The core was securely boxed and labelled at <strong>the</strong> drill site and <strong>the</strong>n transported to <strong>the</strong> projectoffice for geological logging by <strong>EMED</strong>’s geologists.The core was measured, and core recoveries logged by <strong>the</strong> <strong>EMED</strong> geologist. Samples were markedup at regular 1 m intervals without regard to lithology or mineralisati<strong>on</strong>.Behre Dolbear c<strong>on</strong>siders that <strong>EMED</strong>’s sampling procedures are suitable for a bulk disseminated golddeposit such as <strong>Biely</strong> Vrch and c<strong>on</strong>form to modern mining industry standards.14.0 SAMPLE PREPARATION, ANALYSES AND SECURITYThe NQ and HQ diameter core was sawn in half l<strong>on</strong>gitudinally and <strong>the</strong> PQ diameter core intoquarters, and for each 1m sample interval <strong>the</strong> half (or quarter) core was bagged and labelled ready tobe sent for assay.All <strong>the</strong> drill-hole survey data, drill-hole logging data and sample assay data was subsequently enteredinto a computerised database.<str<strong>on</strong>g>NI</str<strong>on</strong>g> <str<strong>on</strong>g>43</str<strong>on</strong>g>–<str<strong>on</strong>g>101</str<strong>on</strong>g> <str<strong>on</strong>g>Technical</str<strong>on</strong>g> <str<strong>on</strong>g>Report</str<strong>on</strong>g> 23 BEHRE DOLBEARLegal*5650400.1