rotary press trailer system specification - The City of Titusville, Florida

rotary press trailer system specification - The City of Titusville, Florida

rotary press trailer system specification - The City of Titusville, Florida

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

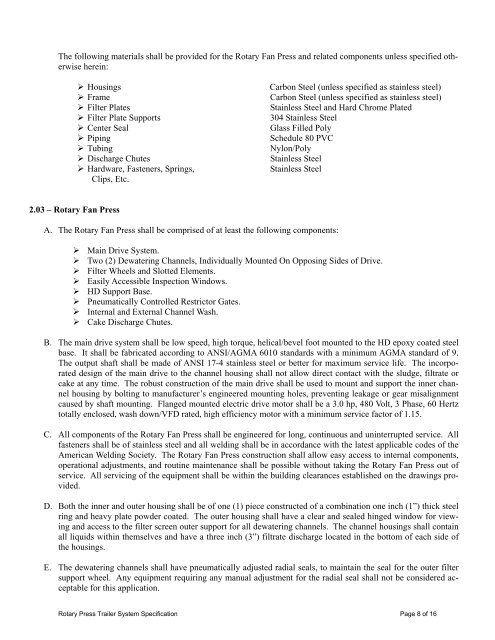

<strong>The</strong> following materials shall be provided for the Rotary Fan Press and related components unless specified otherwiseherein:‣ Housings‣ Frame‣ Filter Plates‣ Filter Plate Supports‣ Center Seal‣ Piping‣ Tubing‣ Discharge Chutes‣ Hardware, Fasteners, Springs,Clips, Etc.Carbon Steel (unless specified as stainless steel)Carbon Steel (unless specified as stainless steel)Stainless Steel and Hard Chrome Plated304 Stainless SteelGlass Filled PolySchedule 80 PVCNylon/PolyStainless SteelStainless Steel2.03 – Rotary Fan PressA. <strong>The</strong> Rotary Fan Press shall be comprised <strong>of</strong> at least the following components:‣ Main Drive System.‣ Two (2) Dewatering Channels, Individually Mounted On Opposing Sides <strong>of</strong> Drive.‣ Filter Wheels and Slotted Elements.‣ Easily Accessible Inspection Windows.‣ HD Support Base.‣ Pneumatically Controlled Restrictor Gates.‣ Internal and External Channel Wash.‣ Cake Discharge Chutes.B. <strong>The</strong> main drive <strong>system</strong> shall be low speed, high torque, helical/bevel foot mounted to the HD epoxy coated steelbase. It shall be fabricated according to ANSI/AGMA 6010 standards with a minimum AGMA standard <strong>of</strong> 9.<strong>The</strong> output shaft shall be made <strong>of</strong> ANSI 17-4 stainless steel or better for maximum service life. <strong>The</strong> incorporateddesign <strong>of</strong> the main drive to the channel housing shall not allow direct contact with the sludge, filtrate orcake at any time. <strong>The</strong> robust construction <strong>of</strong> the main drive shall be used to mount and support the inner channelhousing by bolting to manufacturer’s engineered mounting holes, preventing leakage or gear misalignmentcaused by shaft mounting. Flanged mounted electric drive motor shall be a 3.0 hp, 480 Volt, 3 Phase, 60 Hertztotally enclosed, wash down/VFD rated, high efficiency motor with a minimum service factor <strong>of</strong> 1.15.C. All components <strong>of</strong> the Rotary Fan Press shall be engineered for long, continuous and uninterrupted service. Allfasteners shall be <strong>of</strong> stainless steel and all welding shall be in accordance with the latest applicable codes <strong>of</strong> theAmerican Welding Society. <strong>The</strong> Rotary Fan Press construction shall allow easy access to internal components,operational adjustments, and routine maintenance shall be possible without taking the Rotary Fan Press out <strong>of</strong>service. All servicing <strong>of</strong> the equipment shall be within the building clearances established on the drawings provided.D. Both the inner and outer housing shall be <strong>of</strong> one (1) piece constructed <strong>of</strong> a combination one inch (1”) thick steelring and heavy plate powder coated. <strong>The</strong> outer housing shall have a clear and sealed hinged window for viewingand access to the filter screen outer support for all dewatering channels. <strong>The</strong> channel housings shall containall liquids within themselves and have a three inch (3”) filtrate discharge located in the bottom <strong>of</strong> each side <strong>of</strong>the housings.E. <strong>The</strong> dewatering channels shall have pneumatically adjusted radial seals, to maintain the seal for the outer filtersupport wheel. Any equipment requiring any manual adjustment for the radial seal shall not be considered acceptablefor this application.Rotary Press Trailer System Specification Page 8 <strong>of</strong> 16