Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

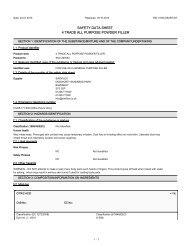

5COMMISSIONING& TESTING5.1 FILLING THE WATER SYSTEMBefore commissioning the appliance, the whole gas installationincluding the meter MUST be purged and tested for gas tightnessin accordance with BS 6891: 1988.!Open all doors and windows, extinguish naked lights,and DO NOT SMOKE whilst purging the gas line.Before commencing the commissioning procedure, ensure that thegas service cock is turned on, the electricity supply is isolated,and that the CH and DHW pipe-work (where fitted) is complete.A special feature of the <strong>CBX</strong> appliances is that the water systemscan be completely filled prior to fitting the appliance. It isrecommended that this procedure be followed even when theappliance is to be fitted immediately after filling the system. Fillthe water systems by following the procedure detailed belowsteps 1 to 5, and referring to Figure 17.It is recommended, where possible, to flush the CHsystem without the appliance fitted, to avoid debrisand flux blocking the waterways within theappliance.17 COMMISSIONING THE WATER SYSTEM1) Check that the CH flow, return, (and DHW return on <strong>SBX</strong>appliance if used), isolating valves are in the open position.2) Fill the system with water using one of the approved methodsdescribed in section 3.7 to about 2.0 bar, (filling loop providedon <strong>CBX</strong> appliances). Vent the system via the radiator valves andsystem air vents in accordance with normal practice. Ensure thatall system air vents are closed.To aid venting, a manual air vent is provided on theLHS of the heat exchanger, and an automatic airvent on the pump assembly.3) Check the system for soundness.4) Check the operation of the pressure relief valve (Figure 18) bylifting the lever on the valve gently to ease the valve of its seat.Checking that water is discharged, release the lever and ensurethat the valve seats correctly and does not leak.18Do not use the pressure relief valve to drain thesystem, because dirt or debris could prevent thevalve seating correctly. If the valve leaks or sticksclosed, then replace it.PRESSURE GAUGECAPILLARYPRESSURE RELIEF VALVECHRETURNCHRETURNCOLDWATER INFILLINGLOOPVALVEGASSUPPLYGASSUPPLYDHWFLOWCHDRAINCHDRAINCHFLOWSECONDARYRETURN FROMTANK (OPTIONAL)FILLINGLOOPCHFLOWFILLINGLOOPVALVECONDENSATE WASTE OUTLET(NOTE: TRAP PARTS FITTEDINSIDE BOILER NOT ONPLUMBING JIG)CONDENSATE WASTE OUTLET(NOTE: TRAP PARTS FITTEDINSIDE BOILER NOT ONPLUMBING JIG)5) Drain the entire system to flush out any debris, and refill to0.2 bar above the system design pressure (between 0.5 and 1.5bar) by repeating the above procedure. Follow the commissioningprocedure described below, and then repeat this instruction withthe system hot. It is recommended that the system be cleaned witha recognised system cleaner such as Fernox or Sentinel.6) On <strong>CBX</strong> appliances, open the DHW inlet valve and operateeach hot water tap in turn to clear all the air from the pipes andthe appliance.7) Remove the pump cap; use a screwdriver to rotate the pumpshaft. Replace the cap.8) Disconnect the filling loop from the system.9) Prior to lighting the appliance to check the gas rates, thecentral heating system should be checked for circulation byoperating the appliance with the gas turned off, this is to ensurethat no air locks occur. The appliance may go into ignitionlockout and require resetting.19