properties as the Mach number decreases, and precise knowledgeof these flight properties is not available. The combinationof rapid change and model uncertainty also makes itdifficult to rely on a single, accurate Orbiter model and aKalman filter design based on that model, or on multiple modelsand gain scheduling. Moreover, the uncertainty also makesit difficult to distinguish between failures in the RCS and in theelevon control surfaces. Even in the absence of any failure, theKalman filter's jet thrust estimation performance degradesconsiderably in the presence of model uncertainty.Even if the Mach number were known accurately, rapid gainscheduling may not be desirable or even possible because ofthe large data storage requirements it entails. In general,however, modeling errors caused by inaccurate knowledge ofthe Mach number and other factors do exist. As a result, theKalman filter will not yield accurate thrust estimates. A desirablesolution, therefore, is a filter architecture that can distinguishrapidly between anomalies in the RCS and in theelevons. The filter architecture must also provide jet thrustestimates even if a jet misfires or an aerosurface fails.The most often used technique to add some measure ofrobustness to an estimator is to increase the design processnoise covariance, i.e., to overdesign the Kalman filter.However, there are limitations to this technique. In particular,it is shown in Refs. [1] and [2] that robust game theoretic or H ∞filters handle model uncertainties better than robustifiedKalman filters. The design of these filters is based on the smallgain theorem. [2]-[8] Such filters are robust to a general class ofnoise and plant model uncertainties. The steady-state robustfilter derived in Ref. [2] has been used in Ref. [9] to estimate theSpace Shuttle Orbiter’s RCS jet thrust. The results in Ref. [9]demonstrate that steady-state robust filters can yieldimproved thrust estimates for a wide range of Mach numbers,although the filter response is unacceptably slow.The effect of model uncertainty on the performance of stateestimators and failure detection algorithms is addressed inRefs. [2] and [10] through [13], among others. In Ref. [14], ageometric interpretation of the concept of analytical redundancyleads to a procedure involving singular-value decompositionsto determine redundancy relations that aremaximally insensitive to model uncertainties. An alternativeapproach is found in Ref. [15], where it is assumed that modelerrors may be deduced from the uncertainties of a set ofunderlying parameters. The partial derivatives of the residualswith respect to these parameters are then computed, and theresidual generator with lowest partial sensitivity is selected. InRefs. [16] through [18], a bound on the effect of model uncertaintieson the residual is estimated. This bound is then usedto set the threshold accordingly. Robust detection methodsbased on the unknown input observer include those of Refs.[12], [19], and [20]. Roughly speaking, an unknown inputobserver is a filter with an output of zero in the absence of failureregardless of the uncertainty and disturbance. Theauthors in Refs. [12] and [20] contributed significantly towardsolving the problem of robust detection using different techniques.Previous work using H ∞ techniques includes the work of Ref.[21], where a steady-state frequency domain-based filterdesign is used to attenuate the effect of disturbances. In Ref.[22], a steady-state H ∞ /µ robust filter for failure detection isintroduced. This filter requires the solution of two Riccatiequations and, as such, is robust to both disturbances andmodel uncertainty. As mentioned earlier, the use of transientfilters for this application is motivated by the work in Ref. [9].In this paper, we build on the work in Ref. [22] by designing afilter architecture based on the transient, discrete-time, robustgame theoretic or H ∞ filters derived in Refs. [2], [6], and [7] thatcan distinguish between failures in the RCS and the aerosurfaces.The failure detection architecture presented consists oftwo robust filters. One filter is tuned to estimate robustly thejet thrust even when jets misfire, whereas the other is tuned todetect failures in the aerosurfaces. Moreover, if a failure in theaerosurfaces is detected, then it is possible to reconfigure thejet thrust estimator to obtain an accurate estimate of the jetthrust. A one-filter architecture is also possible, but the twofilterarchitecture produced quicker detection.In the next section, we formulate the problem and demonstratethe deleterious effect of model uncertainty on the performanceof the Kalman filter, motivating the use of robustfiltering. In the Robust Estimation section, we present a briefformulation of the robust filtering problem. The robust filter’sequations and the Failure Detection and Isolation (FDI) architectureare also presented. Results and conclusions follow.PROBLEM DESCRIPTIONThe RCS consists of 44 bipropellant jets that, together with theaerosurfaces, provide attitude control and limited three-axismaneuvering capability. Thirty-eight of the jets are primaryjets, each capable of providing 870 lb of thrust in vacuum. Thejets are the sole attitude effectors for the initial part of reentrybecause there is insufficient dynamic pressure for the controlsurfaces to be effective in the thin atmosphere. As the vehicleloses altitude, falling into the increasingly denser atmosphere,dynamic pressure increases. The aerosurfaces are then activatedand augment the jets until there is sufficient dynamicpressure to control the attitude with the aerosurfaces alone.We consider the Space Shuttle Orbiter’s lateral dynamics forbank and sideslip. A linear model of the rigid-body reentryrotational dynamics is used as derived by Zacharias. [23]Although originally given in continuous time, the dynamicsare discretized for use with the Orbiter's digital computingsystem. The state-space representation for the Orbiter, linearizedat values of the state and control for an operatingpoint, is given byx k+1 =A k x k +B k u k +G k w k +Tθ ky k =C k x k +D k u k +E k v k (1)where x k is the state of the system at time k, u k is the aerosurface'scontrol input, θ k are the jet inputs, w k is the processnoise, y k is the measurement (angular body rates) vector, and50Robust Failure Detection for Reentry Vehicle Attitude Control Systems

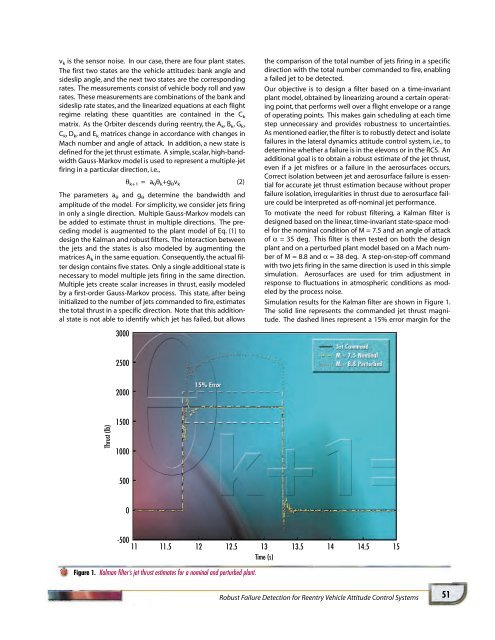

v k is the sensor noise. In our case, there are four plant states.The first two states are the vehicle attitudes: bank angle andsideslip angle, and the next two states are the correspondingrates. The measurements consist of vehicle body roll and yawrates. These measurements are combinations of the bank andsideslip rate states, and the linearized equations at each flightregime relating these quantities are contained in the C kmatrix. As the Orbiter descends during reentry, the A k ,B k ,G k ,C k ,D k , and E k matrices change in accordance with changes inMach number and angle of attack. In addition, a new state isdefined for the jet thrust estimate. A simple, scalar, high-bandwidthGauss-Markov model is used to represent a multiple-jetfiring in a particular direction, i.e.,θ k+1 = a θ θ k +g θ v k (2)The parameters a θ and g θ determine the bandwidth andamplitude of the model. For simplicity, we consider jets firingin only a single direction. Multiple Gauss-Markov models canbe added to estimate thrust in multiple directions. The precedingmodel is augmented to the plant model of Eq. (1) todesign the Kalman and robust filters. The interaction betweenthe jets and the states is also modeled by augmenting thematrices A k in the same equation. Consequently, the actual filterdesign contains five states. Only a single additional state isnecessary to model multiple jets firing in the same direction.Multiple jets create scalar increases in thrust, easily modeledby a first-order Gauss-Markov process. This state, after beinginitialized to the number of jets commanded to fire, estimatesthe total thrust in a specific direction. Note that this additionalstate is not able to identify which jet has failed, but allows3000the comparison of the total number of jets firing in a specificdirection with the total number commanded to fire, enablinga failed jet to be detected.Our objective is to design a filter based on a time-invariantplant model, obtained by linearizing around a certain operatingpoint, that performs well over a flight envelope or a rangeof operating points. This makes gain scheduling at each timestep unnecessary and provides robustness to uncertainties.As mentioned earlier, the filter is to robustly detect and isolatefailures in the lateral dynamics attitude control system, i.e., todetermine whether a failure is in the elevons or in the RCS. Anadditional goal is to obtain a robust estimate of the jet thrust,even if a jet misfires or a failure in the aerosurfaces occurs.Correct isolation between jet and aerosurface failure is essentialfor accurate jet thrust estimation because without properfailure isolation, irregularities in thrust due to aerosurface failurecould be interpreted as off-nominal jet performance.To motivate the need for robust filtering, a Kalman filter isdesigned based on the linear, time-invariant state-space modelfor the nominal condition of M = 7.5 and an angle of attackof α = 35 deg. This filter is then tested on both the designplant and on a perturbed plant model based on a Mach numberof M = 8.8 and α = 38 deg. A step-on-step-off commandwith two jets firing in the same direction is used in this simplesimulation. Aerosurfaces are used for trim adjustment inresponse to fluctuations in atmospheric conditions as modeledby the process noise.Simulation results for the Kalman filter are shown in Figure 1.The solid line represents the commanded jet thrust magnitude.The dashed lines represent a 15% error margin for the2500<strong>2000</strong>Thrust (lb)150010005000-50011 11.5 12 12.5 13 13.5 14 14.5 15Time (s)Figure 1. Kalman filter’s jet thrust estimates for a nominal and perturbed plant.Robust Failure Detection for Reentry Vehicle Attitude Control Systems 51

- Page 6 and 7: V 0 e jωt L R R R TL: (Z 0 ,β,I)C

- Page 9 and 10: Figure 16 shows a fabricated "race-

- Page 11 and 12: ACKNOWLEDGMENTS LEDGMENTSThe author

- Page 13 and 14: aanan MillerRaanan Miller is a Seni

- Page 15 and 16: The motivation for developing ALIP

- Page 17 and 18: (4)where the state variables v and

- Page 19 and 20: q’ = f 1 (q, α, h) (26)q = f 2 (

- Page 21 and 22: 4000Computed Altitude (ft)300020001

- Page 23 and 24: eg H. Bartonbiographies biographies

- Page 25 and 26: ActuatorsSensorsIntelligent Sensors

- Page 27 and 28: Table 2. Potential sensors requirin

- Page 29 and 30: Table 4. Comparison of single-chann

- Page 31 and 32: Using many small I/O networks will

- Page 33 and 34: Network Control ComputersTriple Twi

- Page 35 and 36: Kaplesh KumarAnthony PetrovichTommy

- Page 37 and 38: DESIGN CONSIDERATIONSThe overall go

- Page 39 and 40: BIAS DRIFT STABILITYAn important re

- Page 41 and 42: Hz291206002912050029120400291203002

- Page 43 and 44: In order to show bias repeatability

- Page 45 and 46: nthony PetrovichAnthony Petrovich i

- Page 47: Ramses M. AgustinRami S. MangoubiRo

- Page 51 and 52: The preceding performance criterion

- Page 53 and 54: JET THRUST ESTIMATIONWe will first

- Page 55 and 56: 1st measurement (nominal)0.010.0050

- Page 57 and 58: 45004000350030002500Thrust (lb)2000

- Page 59 and 60: amses AgustinbiographiesRamses Agus

- Page 61 and 62: Jamie M. AndersonPeter A. Kerrebroc

- Page 63 and 64: Figure 1. The Draper Laboratory VCU

- Page 65 and 66: were adjusted to give good tracking

- Page 67 and 68: 80604020Heading (deg)0-20-40-60-800

- Page 69 and 70: Marc S. WeinbergII:"'JI.m-4..... 7.

- Page 71 and 72: where z i is measured from the arbi

- Page 73 and 74: L = beam lengthC = capacitance of e

- Page 75 and 76: 3.02.52.0F/z ratio to linear1.51.00

- Page 77 and 78: The following pages contain the bib

- Page 79 and 80: errors. Numerical testing based on

- Page 81 and 82: of which are high performance and p

- Page 83 and 84: presented.The economic benefits of

- Page 85 and 86: over conventional analyzers. A plan

- Page 87 and 88: Smith, J.; Proulx, R.J.; Cefola, P.

- Page 89 and 90: using a dissolved wafer process wit

- Page 91 and 92: Donald E. GustafsonDavid J. LuciaAu

- Page 93 and 94: onald E. GustafsonbiographiesDonald

- Page 95 and 96: Greiff, Paul; Brezinski, PaulGetter

- Page 97 and 98: DOCTOR ROBERT D. MAURERDr. Maurer l

- Page 99 and 100:

All Draper employees (excluding Off

- Page 101:

Chauddhry, A.I.; Supervisors: Kang,