Multipor External thermal insulation composite system - Xella UK

Multipor External thermal insulation composite system - Xella UK

Multipor External thermal insulation composite system - Xella UK

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Ytong <strong>Multipor</strong> Mineral Insulation Boards<strong>External</strong> <strong>thermal</strong> <strong>insulation</strong><strong>composite</strong> <strong>system</strong><strong>External</strong> <strong>thermal</strong> <strong>insulation</strong> <strong>composite</strong> <strong>system</strong>

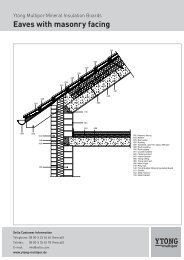

Ytong <strong>Multipor</strong> in external <strong>thermal</strong><strong>insulation</strong> <strong>composite</strong> <strong>system</strong>Ytong <strong>Multipor</strong>: the sustainable external<strong>thermal</strong> <strong>insulation</strong> <strong>composite</strong> <strong>system</strong>In external <strong>thermal</strong><strong>insulation</strong> <strong>composite</strong><strong>system</strong>s, Ytong <strong>Multipor</strong>mineral <strong>insulation</strong>boards provide reliablesolutions..System layout■ Ytong <strong>Multipor</strong> light mortar for gluing on■ Ytong <strong>Multipor</strong> mineral <strong>insulation</strong> board■ Ytong <strong>Multipor</strong> light mortar for reinforcement■ Reinforcement meshPlaster finishes■ Ytong <strong>Multipor</strong> light mortar (floated)■ System-compatible mineral-base finishplastersExterior walls are subject to major temperature variations and varying weather influences.Thermal <strong>insulation</strong> <strong>composite</strong> <strong>system</strong>s applied on the outside reduce heat losses and lower building operatingcosts. This reduces emissions and provides an active contribution to protecting our environment.Ytong <strong>Multipor</strong> in the external <strong>thermal</strong> <strong>insulation</strong> <strong>composite</strong> <strong>system</strong> is suitable for highly subdivided facades as wellas insulating work on large surfaces. It provides a complete, monolithic, mineral-based <strong>system</strong>.<strong>Xella</strong> Deutschland GmbH is an extraordinary member in the Professional Association for <strong>External</strong> ThermalInsulation Composite Systems ( Fachverband Wärmedämm-Verbund<strong>system</strong>e e.V).2 <strong>External</strong> <strong>thermal</strong> <strong>insulation</strong> <strong>composite</strong> <strong>system</strong>

Ytong <strong>Multipor</strong> – the solid exterior <strong>insulation</strong>with stable shape …... for old and new buildingsYtong <strong>Multipor</strong> mineral <strong>insulation</strong>boards are suitable as <strong>thermal</strong> <strong>insulation</strong><strong>composite</strong> <strong>system</strong>s on solidsubsurfaces for renovating facadesand as <strong>thermal</strong> <strong>insulation</strong> onthe exterior walls of new buildings.Cutting work of all types can be accomplishedsimply to fit exactly withoutspecial tools. Experiencedworkmen achieve high installationrates on large surfaces.Universal application... product and <strong>system</strong> approvedby construction supervisoryauthoritiesYtong <strong>Multipor</strong> mineral <strong>insulation</strong>boards – a silicate insulating material.With European Technical ApprovalETA-05/0093.Ytong <strong>Multipor</strong> is generally approvedby construction authorities inexternal <strong>thermal</strong> <strong>insulation</strong> <strong>composite</strong><strong>system</strong>s using one or twolayers up to 300 mm.Simply request!... for facades without <strong>thermal</strong>bridgesThe Ytong <strong>Multipor</strong> external <strong>thermal</strong><strong>insulation</strong> <strong>composite</strong> <strong>system</strong> consistsof a homogeneous insulating layerallowing construction of highly insulatedexterior walls without gaps or<strong>thermal</strong> bridges.Low energy costs... sounds solidWhen subjected to a "tapping test",the Ytong <strong>Multipor</strong> external <strong>thermal</strong><strong>insulation</strong> <strong>composite</strong> <strong>system</strong> soundslike a solid wall and offers maximumquality, hard wearing <strong>thermal</strong> <strong>insulation</strong>.Woodpecker-proof... inhibiting effect to preventformation of algae and mouldYtong <strong>Multipor</strong> external <strong>thermal</strong> <strong>insulation</strong><strong>composite</strong> <strong>system</strong> is biologicallyand microbiologically unobjectionableand has a naturalinhibiting effect to prevent growth ofalgae, mould and micro-organisms.Inhibits algae growth... withstands high mechanicalloadsNon-compressive Ytong <strong>Multipor</strong>mineral <strong>insulation</strong> boards give theentire external <strong>thermal</strong> <strong>insulation</strong><strong>composite</strong> <strong>system</strong> particular stability.Highly resistant... to <strong>thermal</strong> stresses<strong>Multipor</strong> external <strong>thermal</strong> <strong>insulation</strong><strong>composite</strong> <strong>system</strong> reduces longitudinalchanges in the structuralparts resulting from <strong>thermal</strong> forces.Cracks which can usually occur inmixed masonry can be prevented.Even cracks in the facades on oldbuildings can be repaired.Prevents formation of fissures... variable surface finishAll approved plaster finishes in theexternal <strong>thermal</strong> <strong>insulation</strong> <strong>composite</strong><strong>system</strong>, e.g. thin layer mineralbasedfinish plasters are suitablefor finishing the surface. Systemsuppliers offer a variety of coloursfor attractive facades to meet yourpersonal preference.Permanently attractive... ecologically perfectYtong <strong>Multipor</strong> mineral <strong>insulation</strong>boards are classified as an "environmentallycompatible constructionproduct" by the Institute forConstruction and Environment(Institut Bauen und Umwelt e.V.)(IBU e.V.)EPD-XEL-2009212-D, completelyrecyclable and Naturplus qualitysymbol 0404-0812-0881 as biologicallyacceptable and recommendablefor construction. Moreover,wastes and residues can be disposedof easily and economically asconstruction rubble.RecyclableThermally insulating,non-combustible,open for vapour diffusion,solid and stableshape<strong>External</strong> <strong>thermal</strong> <strong>insulation</strong> <strong>composite</strong> <strong>system</strong>3

Ytong <strong>Multipor</strong> external <strong>thermal</strong><strong>insulation</strong> <strong>composite</strong> <strong>system</strong>Exceptional materialproperties and simpleprocessing make Ytong<strong>Multipor</strong> the optimummaterial for exterior<strong>insulation</strong>.Ytong <strong>Multipor</strong> Mineral InsulationBoardsMinerally and ecologically, Ytong<strong>Multipor</strong> mineral <strong>insulation</strong> boardsoffer a new quality for <strong>thermal</strong> <strong>insulation</strong>:■ homogeneous■ high <strong>thermal</strong> <strong>insulation</strong> factor■ non-combustible■ stable shape, non-compressible■ open for vapour diffusion■ water repellent■ ecologicalProductionYtong <strong>Multipor</strong> mineral <strong>insulation</strong>boards are produced in an ecologicaland energy-saving processusing the raw minerals lime, sand,cement and water under steampressure.Ytong <strong>Multipor</strong> Light Mortarfor gluing, reinforcement andplastering■ natural white■ easy processing■ high adhesive force■ good stability■ high yield (30 l/20 kg)■ water repellent■ open for vapour diffusion■ frost-resistant■ non-combustibleDelivery and processing instructions:■ Storage: store dry on pallet, upto 12 months■ Delivery form: 20 kg/sack■ Processing time: approx. 1.5 h■ Ambient temperature: ≥ 5 °CYtong <strong>Multipor</strong> Repair MortarFor repairs and filling damagedpointsAnchorsCan be fastened mechanically withapproved anchors, according tospecifications of <strong>system</strong> partnerPlaster finishesThe following finish plasters aresuitable and <strong>system</strong>-compatiblewith the external <strong>thermal</strong> <strong>insulation</strong><strong>composite</strong> <strong>system</strong> structure withYtong <strong>Multipor</strong> light mortar:■ Thin-layer mineral-based finishplasters according to EN 998-1■ Organic constituents not greaterthan < 2 % by weight■ Capillary water absorptionw ≤ 0.2 kg/m² min. 0,5 ,corresponding to classificationW2 according to EN 998-1■ Water vapour diffusion resistancecoefficient μ ≤ 30■ Dynamic E modulus in <strong>system</strong>structure with Ytong <strong>Multipor</strong>light mortar between 1500 and2000 N/mm²Technical DataApprovalAreas of applicationYtong <strong>Multipor</strong> mineral <strong>insulation</strong> boardEuropean Technical Approval ETA-05/0093General Construction Supervisory ApprovalZ-23.11-1501<strong>External</strong> <strong>thermal</strong> <strong>insulation</strong> <strong>composite</strong> <strong>system</strong>from <strong>system</strong> partners (WAP DIN E 4108-10)Ytong <strong>Multipor</strong>light mortarDensityapprox. 115 kg/m³Thermal conductivity λ = 0.045 W/mK λ 10, dry= 0.18 W/mKWater vapour diffusionresistance coefficientFire classificationμ = 3/5open for vapour diffusionNon-combustible - fire classification A1according to DIN EN 13501-1μ = ≤ 10A2 – non-combustibleBoard Formats/QuantitiesLength x Width 600 x 390 mmThicknessesm 2 /pallet80 mm 21,06100 mm 16,85120 mm 14,04140 mm 11,23160 mm 9,83180 mm 8,42200 mm 8,42Special dimenstions available on requestCompressive strenght Average ≥ 300 kPa CS II – 1.5 – 5.0 N/mm²Bending strength≥ 80 kPa4 <strong>External</strong> <strong>thermal</strong> <strong>insulation</strong> <strong>composite</strong> <strong>system</strong>

<strong>External</strong> <strong>thermal</strong> <strong>insulation</strong> <strong>composite</strong> <strong>system</strong>with Ytong <strong>Multipor</strong>:glue on – plaster over: insulated!Mixing light mortar. 20 kg mixed with 8 l ofwater (mark on measuring bucket) yieldsapprox. 30 l of adhesive mortar.Apply over full surface with toothed trowel(10 or 12 mm teeth) results in adhesive surfaceof at least 70 %.Base height of light mortar approx. 8–10 mm.This allows irregularities up to 5 mm in thesubsurface to be compensated.Press <strong>insulation</strong> board on to wall surface andslide against adjacent board.Ytong <strong>Multipor</strong> <strong>insulation</strong> boards must be fastenedadditionally with suitable anchors.Work reinforcement mesh into Ytong <strong>Multipor</strong>light mortar.Easy to adaptSystem cross-sectionSystem-compatible finish plasterYtong <strong>Multipor</strong> light mortar withYtong <strong>Multipor</strong> reinforcement meshExpanding anchorYtong <strong>Multipor</strong> mineral<strong>insulation</strong> boardYtong <strong>Multipor</strong> light mortarWall materialQuick adaptation to irregularities and attachments.Ytong <strong>Multipor</strong> external <strong>thermal</strong> <strong>insulation</strong><strong>composite</strong> <strong>system</strong> components.<strong>External</strong> <strong>thermal</strong> <strong>insulation</strong> <strong>composite</strong> <strong>system</strong>5

Thermal and acoustic <strong>insulation</strong> forprotection against fire and moistureThermal <strong>insulation</strong>Ytong <strong>Multipor</strong> mineral <strong>insulation</strong>boards consist of 100 % homogeneousmaterial with a heat conductivityof 0.045 W/mK.Minimum energy lossesThermal resistance R (m 2 K)/WThickness(m 2 K)/W80 mm 1,78100 mm 2,22120 mm 2,67140 mm 3,11160 mm 3,56180 mm 4,00200 mm 4,44Thermal <strong>insulation</strong> in summerPrimarily the mass of structurespointing toward the inside as well asthe percentage of window area in theexterior structures are decisive forthe <strong>thermal</strong> <strong>insulation</strong> in summer.Here, external <strong>thermal</strong> <strong>insulation</strong><strong>composite</strong> <strong>system</strong>s attached to theoutside play only a subordinate role.If the insulating material in the external<strong>thermal</strong> <strong>insulation</strong> <strong>composite</strong><strong>system</strong> is calculated by itself, theheat storage capacity of Ytong <strong>Multipor</strong>is relatively high due to its density(115 kg/m³) at the same <strong>insulation</strong>thickness.Stores heatProtection against moistureYtong <strong>Multipor</strong> is treated to ensurethat it is water repellent inside andout. Short rain showers and badweather periods are no problem atall. Ytong <strong>Multipor</strong> mineral <strong>insulation</strong>boards contain only 5 % solidsand are open for vapour diffusion.Ytong <strong>Multipor</strong> does not experienceany mentionable loss in strength inthe wet state.Moreover, this mineral insulatingmaterial with its good <strong>thermal</strong> insulatingand diffusion characteristicsalso ensures a pleasant roomclimate with balanced temperatureand humidity.System open for vapour diffusionFire protectionYtong <strong>Multipor</strong> mineral <strong>insulation</strong>boards are classified as non-combustiblein construction materialclass A1 and the associated Ytong<strong>Multipor</strong> light mortar ensures absolutesafety in the event of a fire.This insulating material does notdevelop any toxic gases or smokeeven at the highest temperatures.This is a true advantage for vitalrescue measures in the event of afire.non-combustibleAcoustic <strong>insulation</strong>In spite of their high porosity of95 % by volume, Ytong <strong>Multipor</strong>mineral <strong>insulation</strong> boards do nothave any negative effect for acoustic<strong>insulation</strong>. The acoustic <strong>insulation</strong>requirements specified in DIN4109 were determined using theacoustic <strong>insulation</strong> value R W. In contrastto most external <strong>thermal</strong> <strong>insulation</strong><strong>composite</strong> <strong>system</strong>s whichdecrease the value by up to 5 dB, itis maintained by Ytong <strong>Multipor</strong>.Since <strong>thermal</strong> <strong>insulation</strong> <strong>composite</strong><strong>system</strong>s are usually used as <strong>thermal</strong><strong>insulation</strong> on exterior walls, theacoustic insulating properties usuallypertain to low frequency trafficnoise.The acoustic insulating factor forthe overall construction is distinguishedby the weighted acoustic <strong>insulation</strong>value R W. Here, the high rigidityof Ytong <strong>Multipor</strong> ensuresgood values.Good acoustic <strong>insulation</strong>6 <strong>External</strong> <strong>thermal</strong> <strong>insulation</strong> <strong>composite</strong> <strong>system</strong>

Acoustic <strong>insulation</strong> and U values forYtong <strong>Multipor</strong> in external <strong>thermal</strong><strong>insulation</strong> <strong>composite</strong> <strong>system</strong>Test results from acoustic measurementson IBPWall structureSilka lime sandstoned = 17.5 cm, ρ = 1800 kg/m 3Acoustic<strong>insulation</strong>value 1)R W52 dBSilka + 6 cm Ytong <strong>Multipor</strong> 54 dB (+2) 2)Silka + 20 cm Ytong <strong>Multipor</strong> 52 dB (+2) 2)Ytongd = 24.0 cm, ρ = 350 kg/m 346 dBYtong + 20 cm Ytong <strong>Multipor</strong> 4,441)Individual value2)Value in parenthesis: Difference in comparisonto uninsulated wall aloneAcoustic <strong>insulation</strong> value for Ytong <strong>Multipor</strong>on Silka wallAcoustic <strong>insulation</strong> value for Ytong <strong>Multipor</strong>on Ytong wallConstruction materialWallthicknessDensityclassThermalconductivityU valueuninsulatedwallInsulation thickness in cm8 10 12 14 16 18 20U value with Ytong <strong>Multipor</strong>(cm) (kg/dm 3 ) (W/mK) (W/m 2 K) (W/m 2 K)*Standard concrete, to DIN 1045 24.0 2.1 2..4 3.52 0.48 0.40 0.34 0.29 0.26 0.23 0.21Silka-R(P) Flat blocks, nach DIN 106 15.0 2.0 1.1 3.26 0.48 0.40 0.34 0.29 0.26 0.23 0.21Silka-R(P) Flat blocks, nach DIN 106 17.5 2.0 1.1 3.04 0.47 0.39 0.33 0.29 0.26 0.23 0.21Silka-R(P) Flat blocks, nach DIN 106 20.0 1.8 0.99 2.69 0.47 0.39 0.33 0.29 0.26 0.23 0.21Silka-R(P) Flat blocks, nach DIN 106 24.0 1.8 0.99 2.42 0.46 0.38 0.33 0.29 0.25 0.23 0.21Solid/hollow brick solid blocks 24.0 2.0 0.96 2.38 0.46 0.38 0.32 0.28 0.25 0.23 0.21Solid blocks (Vbl) LB, to DIN 18152 24.0 1.8 0.87 2.24 0.45 0.38 0.32 0.28 0.25 0.22 0.20Cinder blocks, to DIN 398 24.0 2.0 0.76 2.06 0.44 0.37 0.32 0.28 0.25 0.22 0.20Solid blocks (V) LB, to DIN 18152 24.0 1.6 0.74 2.02 0.44 0.37 0.32 0.28 0.25 0.22 0.20Silka-R(P) Flat blocks, nach DIN 106 24.0 1.4 0.70 1.95 0.44 0.37 0.31 0.28 0.25 0.22 0.20Solid bricks, old building 38.0 2.0 1.05 1.88 0.43 0.36 0.31 0.27 0.24 0.22 0.20Hollow blocks LB, to DIN 18151 24.0 1.0 0.64 1.83 0.43 0.36 0.31 0.27 0.24 0.22 0.20Solid/hollow brick solid blocks 24.0 1.2 0.50 1.54 0.41 0.35 0.30 0.27 0.24 0.21 0.20Cinder blocks, to DIN 398 24.0 1.0 0.47 1.47 0.41 0.34 0.30 0.26 0.24 0.21 0.20LHIz A+B, to DIN 105/2 24.0 0.8 0.39 1.27 0.39 0.33 0.29 0.26 0.23 0.21 0.19Solid blocks (Vbl) LB, to DIN 18152 24.0 0.8 0.39 1.27 0.39 0.33 0.29 0.26 0.23 0.21 0.19Solid blocks (V) LB, to DIN 18152 24.0 0.5 0.32 1.09 0.37 0.32 0.28 0.25 0.22 0.20 0.19LHIz W, to DIN 105/2 24.0 0.7 0.3 1.03 0.36 0.31 0.27 0.25 0.22 0.20 0.19Hollow blocks LB, to DIN 18152 24.0 0.5 0.29 1.00 0.36 0.31 0.27 0.24 0.22 0.20 0.18Ytong, to DIN 4065 24.0 0.8 0.29 1.00 0.36 0.31 0.27 0.24 0.22 0.20 0.18Ytong, to DIN 4065 24.0 0.5 0.22 0.79 0.33 0.29 0.25 0.23 0.21 0.19 0.18LHIz T, to approval 30.0 0.8 0.21 0.63 0.30 0.26 0.23 0.21 0.19 0.18 0.17LHIz T18, to approval 36.5 0.8 0.18 0.46 0.25 0.23 0.21 0.19 0.19 0.16 0.15Ytong, to DIN 4065 24.0 0.5 0.12 0.46 0.25 0.23 0.21 0.19 0.19 0.16 0.15* The plaster layers were not taken into consideration in calculating the U values. Thermal bridge catalogue www.multipor.deU value for old building ‹ 0.35 (W/m 2 k) U value for low energy house ‹ 0.22 (W/m 2 k)<strong>External</strong> <strong>thermal</strong> <strong>insulation</strong> <strong>composite</strong> <strong>system</strong>7

Note: This brochure was published by <strong>Xella</strong> Dämm<strong>system</strong>e GmbH. Our publications provide advise andinformation according to the best of our knowledge and the state of the art at the time of publication.Since legal rules and regulations are subject to change, this information is not legally binding.It is necessary to check the applicable regulations in each individual case.Edition 07/2009<strong>Xella</strong> Customer InformationTelephone: 08 00-5 23 56 65 (freecall)Telefax: 08 00-5 35 65 78 (freecall)www.ytong-multipor.deYtong and <strong>Multipor</strong> are registered trademarks of the <strong>Xella</strong> Group8 <strong>External</strong> <strong>thermal</strong> <strong>insulation</strong> <strong>composite</strong> <strong>system</strong>