BB-9 Product Line Catalog - Flow Ezy Filters

BB-9 Product Line Catalog - Flow Ezy Filters

BB-9 Product Line Catalog - Flow Ezy Filters

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

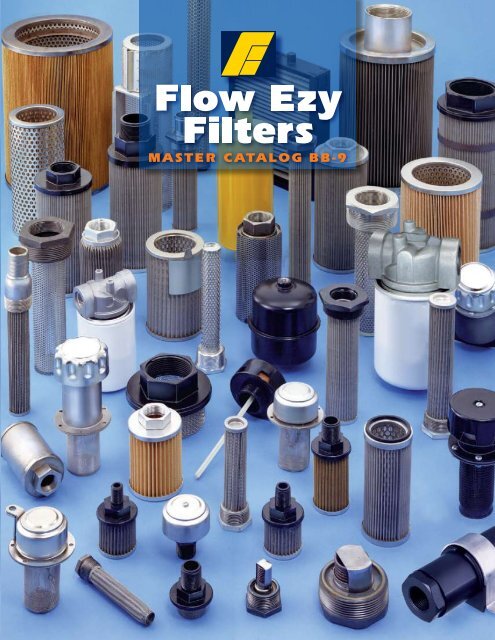

A COMPLETE LINEOF HYDRAULIC FILTERS,STRAINERS AND ACCESSORIESWe have designed and engineeredour complete product line of qualityfiltration products to meet exactingstandards, giving you superior, costeffectiveperformance. We don't justrest on our reputation of providing onlythe best products, we strive to keep it.If you feel the need to contact usfor any reason, we encourage youto do so. As our customer, whatyou have to say is important to us.If you don't find what you're lookingfor in these pages, give us a call.We're very experienced in producing"specials" that meet our customers'needs. (We may have alreadybuilt a model similar to yourrequirements.) So for any reason,please give us a call.For questions or to place an order,contact us 24 hours a day, 7 daysa week by fax or on the internet.We can also be reached by phone8 AM to 5 PM eastern standard time.Call us at734-665-8777 or 800-237-1165Fax us at734-665-4432 or 800-252-1730Or reach us on our website atwww.flowezyfilters.comOr e-mail us atflowezy@flowezyfilters.comMasterCard®S®AMERICANEXPRESSFLOW EZY FILTERSP.O. Box 1749Ann Arbor, MI 48106Tel 734-665-8777 or 800-237-1165Fax 734-665-4332 or 800-252-17301

SALES AND RETURN POLICYPRICINGAll prices are FOB Ann Arbor, MI. All pricing subject to change without notice.QUOTESAll items not listed in current price lists are subject to quote. All quotes are net costand are FOB Ann Arbor, MI. Unless otherwise stated all quotes are good for 30 days.Blanket quotes are handled on an individual basis.PAYMENTSStandard terms of payment is net 30 days from date of invoice. All past due accounts aresubject to 1-1/2% per month on the unpaid balance. Credit hold may take place at 60 days.GENERALAll clerical errors are subject to correction.RUSH ORDERS (UPS RED, BLUE, ORANGE, FEDERAL EXPRESS, ETC.)Orders must be received no later than 2:00 p.m. Eastern Time in order to be shippedthe same day.SHIPMENTS VIA THE POSTAL SERVICEThere will be a $25.00 flat additional fee charged for any shipment which requires useof the postal service.SPECIAL ORDERSSpecial orders may require partial or complete prepayment before beginning production.CANCELLATIONSSpecial orders for elements that are built to the customer's specifications cannot be canceledif the order is in production, without cancellation charges.ADDITION OF ITEMS TO EXISTING ORDERSAdditional items cannot be added to orders that exist but have not shipped.RETURNSNo goods may be returned without prior authorization and RGA number givenby <strong>Flow</strong> <strong>Ezy</strong> <strong>Filters</strong>,Inc.Shipping discrepancies must be brought to the attention of <strong>Flow</strong> <strong>Ezy</strong> <strong>Filters</strong> within 20 daysof receipt of goods.Special orders built to the customer's specifications cannot be returned.All authorized returns must be in the original packaging in the original condition andshipped freight prepaid.<strong>Flow</strong> <strong>Ezy</strong> <strong>Filters</strong>, Inc. reserves the right to issue credit for returned goods upon inspectionof the same.Original purchase order, invoice number, and invoice date of the product being returned must begiven to <strong>Flow</strong> <strong>Ezy</strong> <strong>Filters</strong> before a Returned Goods Authorization (RGA) number will be given.2

INDEXSUMP STRAINERSPageAll-Metal Sump Strainers 4All-Steel Sump Strainers 4Nylon Connector Sump Strainers 5All-Stainless Sump Strainerswith Nylon Connector 5Crimped-End Sump Strainers 6Disposable Sump <strong>Filters</strong> 6CASS and MASS Strainers 7Double Element Sump <strong>Filters</strong> 8WASS Mini Suction Strainers 8Nylon Suction Strainers 10Series AN-6235 10Texas Strainers 9Tank-Mounted Strainers 11-13<strong>Flow</strong> Diffusers 14strainer MAGNETS 14Pipe-mounted suction screens 15Tank Filler-BreathersTop-Mounting Units 16AccessoriesPerforated Inner Guard 16Magnet and Post 16Dipstick 20Padlock Adapted 16Stainless Steel 16Removable Basket Units 17All-Nylon Top-Mounting Units 18Units for Pressurized Tanks 18Side-Mounting Units 19TANK BREATHERSBF Models 20NBF Models 20Spin-On Filter Elements 21Spin-On Air Breather Adapters 21Giant Tank Breathers 22PageBACK-PRESSURE INDUCERS 23JET PNEUMATIC EXHAUST MUFFLERS 23SPIN-ON FILTERS 24REUSABLE MAGNETS FOR SPIN-ON 25REPLACEMENT LUBE FILTERS 25300 PSI INLINE FILTERS 26LOW COST IN-LINE FILTERS10-GPM In-<strong>Line</strong> <strong>Filters</strong> 277050 Series 271500 and 3000-psi In-<strong>Line</strong> <strong>Filters</strong> 28CARTRIDGE FILTER HOUSINGS 29MELTBLOWN CARTRIDGES 30INDUSTRIAL PROCESS FILTER CATRIDGES 31A 2 -SERIES CARTRIDGE FILTER ELEMENTS 32FILTERSY-<strong>Filters</strong> 33-34T-<strong>Filters</strong> 35-36Texas <strong>Filters</strong> 37-38Tee-<strong>Ezy</strong> <strong>Filters</strong> 39-40HIGH- CAPACITY FILTERS/STRAINERS,Models 4-6-8 41-45PLEATED BAGS FOR BAG FILTERS 46OIL-ABSORBING INSERT CARTRIDGES 47HYDRAULIC FLANGES 48PORTABLE OIL TRANSFER ANDFILTER SYSTEM 48HIGH QUALITY WIRE CLOTH 49REPLACEMENT ELEMENTS 50-82OTHER FLOW EZY CATALOGS 833

SUMP STRAINERS – All Metal - All SteelSump strainers are used inhydraulic fluids, coolants,lubricants, and many processfluids. <strong>Flow</strong> <strong>Ezy</strong> offers them inmany different constructionsto better match a variety ofapplications. All have strongperforated metal support tubesunder the straining elements.All are available with optional,built-in bypass relief valves toavoid starving the pump shouldthe strainer become dirt-clogged.ALL-METALCONSTRUCTIONThe traditional all-metal sumpstrainer has stainless steelpleated elements, in mesh sizes30 to 200. Continuous epoxybondedjoints will not leak fluidaround the element. They maybe cleaned and used indefinitely.ALL-STEELCONSTRUCTIONAll-steel sump strainers (StyleAS) provide greater strength.Otherwise they are the sameas the standard unit.(Not a stocked item.)REVERSETAPEREPOXYHOW TO ORDERSelect the desired specifications from the ordering table andbuild an ordering code number, as shown in this sample:AS - 75 - 2-1/2 - NIPPLE - 100 - RV-3STYLE - GPM - NPT - CONNECTION - MESH - VALVE(spell out NIPPLE(omit ifif wanted)not wanted)STYLE GPM NPT CONNECTION MESH RELIEF(<strong>Flow</strong> (Pipe (Nut or (Screen VALVECapability) size) Nipple) size) (Optional)ALL 2 1/4*, 1/2* no 30METAL 3 3/8, 1/2* symbol RV-3no symbol 3 3/4 (nut) (3-psi(aluminum 5 3/4, 1 60 bypass)thd. end) 10 3/4, 1 nipple20 1-1/4 (to getALL 30 1-1/2 nipple 100STEEL 50 1-1/2&2 you must RV-5AS 75 2-1/2 specify it) (5-psi100 3 200 bypass)*Relief Valve not available(Pressure drop through a clean element will not exceed 0.2 psi(0.4-in. Hg) at rated flow of 150 SSU viscosity fluid and 100 mesh.)DIAMETERNUT STYLE (All-steel construction)GPM SCREEN AREA NPT OVERALLRATING (Sq. Inches) (Pipe DIMENSIONSSize) Diameter Length3 35 3/8, 1/2, 3/4 2-1/8 2-11/165 50 3/4, 1, 1-1/4 3-1/16 3-1/1610 110 3/4, 1, 1-1/4 3-1/16 5-5/1620 DIAMETER 145 3/4, 1, 1-1/4 3-1/16 7-1/830 260 1-1/2 4-1/16 9-5/850 280 1-1/2 & 2 4-1/16 9-5/875 350 2-1/2 5-1/16 12-5/8100 450 3 5-1/16 12-5/8Slot holding epoxy adhesive hasa reverse taper on both sides toensure a positive interlock on allstrainers.MagnetsAvailable-See Page14DIAMETERDIAMETERDIAMETERLENGTHLENGTHLENGTHNUT STYLE (Metal construction w/cast aluminum top)DIAMETER2 25 1/4,1/2 1-1/4 43 35 3/8, 1/2, 3/4 2-1/8 2-11/165 50 3/4 & 1 3-9/32 3-1/210 110 3/4, 1, 1-1/4 3-9/32 5-3/420 145 3/4,1, 1-1/4 3-9/32 7-3/8DIAMETERDIAMETER30 260 1-1/2 4-9/32 9-3/450 280 1-1/2 & 2 4-9/32 9-3/475 350 2-1/2, 3 5-7/16 12-1/2100 450 2-1/2, 3 5-7/16 12-1/2150 675 3 5-7/16 17-3/4LENGTHNIPPLE STYLE (All-metal construction)LENGTHLENGTHGPM SCREEN AREA NPT OVERALLRATING (Sq. Inches) (Pipe DIMENSIONSSize) Diameter LengthDIAMETERDIAMETERGPM SCREEN AREA NPT OVERALLRATING (Sq. Inches) (Pipe DIMENSIONSSize Diameter LengthLENGTHLENGTH2 30 1/4,1/2 1-1/4 4-3/83 40 3/8, 3/4 2-1/16 2-7/85 62 3/4, 1 3-1/16 3-11/1610 125 1 3-1/16 620 162 1-1/4 3-1/16 7-9/1630 310 1-1/2 4 9-3/450 340 1-1/2, 2 4 9-3/475 400 2-1/2, 3 5-1/16 12-5/8100 500 2-1/2, 3 5-1/16 12-3/4LENGTHLENGTH4

SUMP STRAINERS – Nylon ConnectorHOW TO ORDERSelect the desired specifications from the ordering table andbuild an ordering code number, as shown in this sample:P - 50 - 2 - NIPPLE - 100 - RV-3STYLE - GPM - NPT - CONNECTION - MESH - VALVE(spell out NIPPLE if wanted)(omit if not wanted)STYLE GPM NPT CONNECTION MESH VALVE(<strong>Flow</strong> (Pipe (Nut or (Screen (Optional)Capacity) size) Nipple) size)2 1/8,1/4,3/8,1/2 Nut Only3 1/4PNut or Nipple(std. 3 3/8,1/2, 3/4 (to get nipple you 30 RV-3Nyl-End) must specify it) (3-psibypass)60PASS 5 3/4, 1, 1-1/4 Nut(S.S. 10 3/4, 1, 1-1/4 no symbolNyl-End) 20 3/4, 1, 1-1/4 100 RV-530 1-1/2 & 2 Nipple Style (5-psi50 1-1/2 & 2 (see chart below) bypass)50 2-1/2 Nipple Only 20075 2-1/2 Nut or Nipple100 3 (to get nipple you150 3 must specify it)NYLON CONNECTOR TYPE“Nyl-End” sump strainers (Style P)are made with the same selectionof stainless steel elements as thestandard all-metal units. They differin that the connector end pieces aremolded in a single piece of glassreinforcednylon resin. Pleatedstainless elements are epoxybondedin place.They're as serviceable as all-metalunits, but they cost 12 to 50 percentless, depending on size.ALL-STAINLESSCONSTRUCTIONAll-stainless-steel sump strainers withnylon connectors (Style PASS) areavailable in the same wide variety ofsizes and element mesh sizes as thestandard Nyl-End units. For excellentresistance to oxidation and corrosion.(Not always a stocked item.)(Pressure drop through a clean element will not exceed 0.2 psi(0.4-in. Hg) at rated flow of 150 SSU viscosity fluid.)NUT STYLENIPPLE STYLEGPM SCREEN AREA NPT OVERALLRATING (Sq. Inches) (Pipe DIMENSIONSSize) Diameter LengthDIAMETERGPM DIAMETER SCREEN AREA NPT OVERALLRATING (Sq. Inches) (Pipe DIAMETERDIMENSIONSSize) Diameter LengthDIAMETER2 30 1/8,1/4,3/8,1/2 1-5/8 4-3/163 35 1/4,3/8,1/2,3/4 2-1/4 2-11/165 50 3/4, 1, 1-1/4 3-3/16 3-1/210 110 3/4, 1, 1-1/4 3-3/16 5-3/420 145 3/4, 1, 1-1/4 3-3/16 7-3/830 260 1-1/2, 2 4-3/16 9-3/450 280 1-1/2, 2 4-3/16 9-3/475 350 2-1/2, 3 5-3/16 12-1/2100 450 2-1/2, 3 5-3/16 12-1/2150 675 3 5-3/16 17-3/4LENGTH3 35 3/8, 1/2, 3/4 2-1/4 3-3/45 50 1 3 3-13/610 110 1 3 6-1/1620 145 1 3 7-11/1630 260 1-1/2 4-3/16 11-3/830 260 2 4-3/16 11-3/850 280 1-1/2 4-3/16 11-3/850 280 2 4-3/16 11-3/850* 280 2-1/2 4-3/16 9-15/1675 350 2-1/2, 3 5-3/16 13-3/4100 450 2-1/2, 3 5-3/16 13-3/4150 675 3 5-3/16 19LENGTHLENGTHLENGTH*No hex between nipple and strainer on this partREVERSETAPEREPOXYMagnetsAvailable-See Page14DIAMETERLENGTHDIAMETERLENGTHDIAMETERDIAMETERLENGTHLENGTHDIAMETERLENGTHDIAMETERSlot holding epoxy adhesive hasa reverse taper on both sides toensure a positive interlock forstrongest possible connection.5

SUMP STRAINERS – Crimped End and DisposableCRIMPED-END STRAINERSThese are truly all-metal sump strainers, asthey do not have any epoxy in their construction.The stainless steel elements are secured throughstrong mechanical crimping. Good for almostany fluid, especially those that attack epoxymaterials. Also for high-temperature applications.HOW TO ORDERSelect the desired specifications from theordering table and build an ordering codenumber, as shown in this example:C - 50 - 2 - NIPPLE - 60 - RV-3STYLE - GPM - NPT - CONNECTION - MESH - VALVE(spell out NIPPLE(omit ifif wanted)not wanted)GPM NPT CONNECTION MESH VALVESTYLE (<strong>Flow</strong> (Pipe (Nut or (Screen (Optional)Capacity) Size) Nipple) Size) DIAMETERC 5 3/4DIAMETERno symbol 30 RV-3(Crimped) 10 1 (nut) (3-psi20 1-1/4 60 bypass)30 1-1/2 To get NIPPLE50 1-1/2 you must 100 RV-52 specify it (5-psi75 2-1/2 200 bypass)100 3(Pressure drop through a clean element will not exceed 0.2 psi(0.4-in. Hg) at rated flow of 150 SSU viscosity fluid.)NUT STYLEDIAMETERDIAMETER DIAMETERNPT OVERALLGPM SCREEN AREA (Pipe DIMENSIONSRATING (Sq. Inches) Size) Diameter Length5 50 3/4 & 1 2-7/8 3-1/810 110 1 2-7/8 5-3/820 145 1-1/4 2-7/8 7-1/830 260 1-1/2 3-7/8 9-5/850 280 1-1/2 & 2 3-7/8 9-5/875 350 2-1/2 5 12-11/16100 450 3 5 12-11/16LENGTHLENGTHLENGTHLENGTHLENGTHDIAMETERDIAMETERLENGTHLENGTHDISPOSABLE FILTERSThese sump filters eliminate the need forcleaning. When fitted with a 10 or 20-micronpaper (cellulose) element, they have threetimes the the dirt carrying capacity of a 74micron metal screen type. When a 40-micronsynthetic fiber element is used, the capacityis six times as great as with the metal units.The pleated paper element is fully supportedby a perforated metal tube. These disposable-typesump strainers can also be used as replacementfilter elements in many filter housings (thatprovide a male NPT connection).HOW TO ORDERSelect the desired specifications from theordering table and build an ordering code number,as shown in this example:CS - 3 - 3/4 - 20 - RV-5STYLE - GPM - NPT - MICRONS - VALVE(omit if not wanted)GPM NPTSTYLE (<strong>Flow</strong> (Pipe MICRON VALVECapacity) Size) (Nominal) (Optional)CS 1 1/2 10C*RV-3(paper)3 3/4 20C*(3-psi bypass)40A†RV-510 1 (5-psi bypass)*Cellulose †Synthetic(Pressure drop through a clean element will not exceed 0.5 psi(1-in. Hg) at rated flow of 150 SSU viscosity fluid.)NIPPLE STYLENPTDIAMETEROVERALLGPM SCREEN AREA (Pipe DIMENSIONSRATING (Sq. Inches) Size) Diameter Length5 50 3/4 2-7/8 3-1/210 110 1 2-7/8 5-3/420 145 1-1/4 2-7/8 7-5/1630 260 1-1/2 3-3/4 9-5/850 280 1-1/2 3-3/4 9-5/875 350 2-1/2 5 12-5/8100 450 3 5 12-5/8LENGTHDIAMETERLENGTHFILTERINGOVERALLGPM AREA MICRONS DIMENSIONSRATING (Sq. In.) (Nominal) (Absolute) Diameter LengthDIAMETER1 150 10,20,40 40,50,100 3 4-5/83 450 10,20,40 40,50,100 4 8-3/810 700 40 100 4-1/2 710 1400 10,20 40,50 4-1/2 14LENGTHDIAMETERLENGTHDIAMETERLENGTHDIAMETERDIAMETERDIAMETERMagnetsAvailable-See Page14LENGTHLENGTHLENGTH6

SUMP STRAINERS – All Stainless SteelHOW TO ORDERSelect the desired specifications from the ordering table andbuild an ordering code number, as shown in this sample:CASS - 30 - 1-1/2 - NIPPLE - 200 - RV-3STYLE - GPM - NPT - CONNECTION - MESH - VALVE(spell out NIPPLE(omit ifif wanted)not wanted)STYLE GPM NPT CONNECTION MESH VALVE(<strong>Flow</strong> (Pipe (Nut or (Screen (Optional)Capability) size) Nipple) size)CASS 5 3/4,1,1-1/4 no 30 RV-3 DIAMETER10 3/4,1,1-1/4 symbol DIAMETER(3-psi20 3/4,1,1-1/4 (coupling) 60 bypass)30 1-1/250 1-1/2 & 2 nipple 10075 2-1/2 (to get nipple RV-5100 3 you must 200 (5-psispecify it)bypass)(Pressure drop through a clean element will not exceed 0.2 psi(0.4-in. Hg) at rated flow of 150 SSU viscosity fluid and 100 mesh.)LENGTHLENGTHDIAMETERLENGTHLENGTHCASS SERIES ALLSTAINLESS STEELThis all stainless steel crimpedsump strainer comes in meshsizes 30 to 200. Perforatedinner support assures a strong,long-lasting strainer that can becleaned and used indefinitely.MagnetsAvailable-See Page14COUPLING STYLENPT OVERALLGPM SCREEN AREA (Pipe DIMENSIONSRATING (Sq. Inches) Size) Diameter Length5 50 3/4,1,1-1/4 2-7/8 3-1/810 110 3/4,1,1-1/4 2-7/8 5-7/1620 145 3/4,1,1-1/4 2-7/8 7-3/1630 260 1-1/2 3-3/4 8-13/1650 280 1-1/2 3-3/4 9-5/850 280 2 3-3/4 9-5/875 350 2-1/2 5 12-7/16100 450 3 5 12-1/2DIAMETERLENGTHLENGTHDIAMETERLENGTHLENGTHNIPPLE STYLENPT OVERALLGPM SCREEN AREA (Pipe DIMENSIONSRATING (Sq. Inches) Size) Diameter Length5 50 3/4 2-7/8 3-1/210 110 1 2-7/8 5-3/420 145 1-1/4 2-7/8 7-5/1630 260 1-1/2 3-3/4 9-5/850 280 1-1/2 3-3/4 9-5/850 280 2 3-3/4 9-5/875 350 2-1/2 5 12-5/8100 450 3 5 12-5/8HOW TO ORDERSelect specifications from the ordering table and build ordering code:STYLE GPM NPT CONNECTION MESH VALVE(<strong>Flow</strong> (Pipe (Nut or (Screen (Optional)Capability) size) Nipple) size)MASS 2 3/8,1/2 no 30 RV-33 3/8,1/2,3/4 symbol (3-psi5 3/4,1,1-1/4DIAMETER(coupling) 60 bypass)10 3/4,1,1-1/420 3/4,1,1-1/4 nipple 10030 1-1/2 (to get nipple RV-550 1-1/2,2 you must 200 (5-psi75 2-1/2 specify it) bypass)100 3LENGTHLENGTHDIAMETERLENGTHLENGTHMASS SERIES ALLSTAINLESS STEELAll stainless steel sump strainers withcontinuous epoxy-bonded end caps.Magnets Available-See Page 14COUPLING STYLENPT OVERALLGPM SCREEN AREA (Pipe DIMENSIONSRATING (Sq. Inches) Size) Diameter Length2 30 3/8,1/2 1.34 4-1/43 35 3/8,1/2,3/4 2-1/32 2-11/165 50 3/4,1,1-1/4 3-1/16 3-1/1610 110 3/4,1,1-1/4 3-1/16 5-9/1620 145 3/4,1,1-1/4 3-1/16 7-1/830 260 1-1/2 4-1/16 8-3/450 280 1-1/2 4-1/16 9-5/850 280 2 4-1/16 9-5/875 350 2-1/2 5-1/16 12-5/8100 450 3 5-1/16 12-5/8DIAMETERLENGTHLENGTHDIAMETERLENGTHLENGTHNIPPLE STYLENPT OVERALLGPM SCREEN AREA (Pipe DIMENSIONSRATING (Sq. Inches) Size) Diameter Length2 30 3/8,1/2 1.34 4-1/23 40 3/8,1/2,3/4 2-1/32 2-7/85 62 3/4,1 3-1/16 3-11/1610 125 3/4,1,1-1/4 3-1/16 620 162 1-1/4 3-1/16 7-9/1630 305 1-1/2 4-1/16 9-3/1650 330 1-1/2 4-1/16 9-13/1650 330 2 4-1/16 9-13/1675 390 2-1/2 5-1/16 12-3/4100 500 3 5-1/16 12-3/47

DOUBLE ELEMENT SUMP FILTERSSUCTION STRAINERSREPLACES PRODUCTS FOR:Michigan Fluid Power (MFP)Fluid Power <strong>Product</strong>sAmbac Fluid PowerFluid Power SystemsThese high-quality sump filtersmeet the special requirementsfor use with hydraulic oils,coolants, lubricants, and fireresistantfluids. They have aunique dual-elementconstruction that provides amuch larger filtering area thanstandard units. This greaterfiltration capacity makes themideal for use in the followingindustries: agriculture,construction, generalindustrial, material handling,chemical, petroleum, machinetool & metalworking, andprocessing."WASS" style sump strainers are mini-type,welded, and all 304 stainless steel for virtuallyany fluid compatibility issues. The ends aresecured through mechanical crimping.No epoxy is used in the manufacturing ofthese units. For low-flow applications.HOW TO ORDERSelect the desired specifications from theordering table and build an ordering codenumber, as shown in this example:PORT ELEMENT HEXGPM SIZE AREA A B C DNPT SQ. IN.10 1 130 1-5/8 4-1/16 3-1/8 315 1 170 1-5/8 5-1/16 4-1/8 320 1-1/4 230 2 6-1/16 5-1/8 330 1-1/2 370 2-1/4 6-1/16 5-1/8 450 2 450 2-3/4 7-1/16 6-1/8 475 2-1/2 540 3-9/16 7-1/16 6-1/4 5100 3 720 4 8-5/16 7-1/4 5150 3 920 4 10-5/16 9-1/4 5HOW TO ORDER DUAL ELEMENT SUMP FILTERSA DCBWASS - 3 - 1/2 - NIP - 60 - RV-3STYLE - GPM - NPT - CONNECTION - MESH - VALVE(spell out NIP(omit ifif wanted)not wanted)GPM NPT CONNECTION MESH VALVESTYLE (<strong>Flow</strong> (Pipe (Nut or (Screen (Optional)Capacity) Size) Nipple) Size)WASS 3 3/8 no symbol 30 no symbol(coupling)(omitted)1/2 60NIPRV-33/4* (nipple) 100 (3-psi)* 3/4 coupling not available** 50 x 200 mesh available200** RV-5(5-psi)Select the desired specifications from the data below andbuild an ordering code number, as shown in the example:2-1/2SR - 75 - 2-1/2 - 100 - RV-3STYLE - GPM - NPT - MESH - VALVE(omit ifnot wanted)STYLE GPM NPT MESH VALVE(<strong>Flow</strong> (Pipe (Screen (Optional)Capacity) Size) Size)NPT LENGTHCOUPLING NIPPLE3/8 3-1/16 3-1/21/2 3-1/4 3-1/23/4 N/A 3-1/21-3/42-1/2ASU 10 1 60 RV-3without 15 1 (3-psibypass 20 1-1/4 bypass)SR 30 1-1/2 100with 50 2bypass 75 2-1/2100 3150 31-3/4A(Pressure drop through a cleanelement will not exceed 0.2 psi(0.4-in. Hg) at rated flow of150 SSU viscosity fluidand 100 mesh.)Magnets are available,order separately.MagnetsAvailable-See Page14WASS NippleWASS Coupling8

TEXASSTRAINERSHOW TO ORDERSelect the desired specifications from the ordering table andbuild an ordering code number, as shown in this sample:200 - 2 - N - 5.9 - 30 - RV-3 - ALSSGPM - NPT - CONNECTION - DIA. - MESH - VALVE - STYLEGPM NPT CONNECTION DIA. MESH VALVE STYLE(<strong>Flow</strong> (Pipe (Coupling or (In.) (Screen (Optional)Capacity) Size) Nipple) Size)200 2 no symbol 5.9 30 RV-3 ALSS3 (coupling) (3-psi (all stainless4 8.1 60 bypass) steel-6 omit if10.2 100 not300 3 N wanted)4 (nipple) 200 RV-56 (5-psibypass)400 4600 6*Bypass valve will not handle 100% of rated flow.These are BIG suction strainersthat screw into reservoir suctionpipes as large as six inches indiameter, to handle flow ratesas high as 600 gpm. Stainlesswire screens as fine as200 mesh and either male(nipple) or female (coupling)connections may be ordered.Each flow size is offered inmore than one length/diameterratio size, to better fit youravailable space.Standard Texas strainers aremade with mild steel supporttubes, end caps, and fittings.They’re epoxy bonded forleak-proof service.FLOW RATINGS(based on 150 SUS oil) 200 GPM 300 GPM 400 GPM 600 GPMELEMENT AREA(sq. in. of wire cloth) 1070 965 860 1340 1370 1175 1905 1740 1665 2430 2370OUTSIDE DIAMETERS (in.) 5.9 8.1 10.2 5.9 8.1 10.2 5.9 8.1 10.2 8.1 10.2OVERALL LENGTHS (in.)With 2" COUPLING 13-5/8 10-3/16 8 Call2" NIPPLE 14-3/4 11-5/16 9-1/8 FactoryDIMENSION TABLE3" COUPLING 14-3/4 11-5/16 9-1/8 18-1/16 14-3/4 11-5/163" NIPPLE 15-1/8 11-11/16 9-1/2 18-7/16 15-1/8 11-11/164" COUPLING 15-9/16 11-9/16 9-3/8 18-7/8 15 11-9/16 24-3/4 18-3/16 14-15/16 24-3/16 19-15/164" NIPPLE 15-13/16 11-13/16 9-5/8 19-1/8 15-1/4 11-13/16 25 18-7/16 15-3/16 24-7/16 20-3/166" COUPLING 12-5/8 9-7/8 16 12-1/16 19-1/4 15-7/16 25-1/4 20-7/166" NIPPLE 12-3/4 10 16-1/8 12-3/16 19-3/8 15-9/16 25-3/8 20-9/16MagnetsAvailable-See Page14ALL-STAINLESSCONSTRUCTIONTexas strainers are availableconstructed entirely of stainlesssteel, in the same wide varietyof sizes and element meshsizes as the standard units.9

NYLON SUCTION STRAINERSSERIES AN-6235• ECONOMICAL• DISPOSABLE• ALL-NYLON CONSTRUCTION• 30 MESH-SIZE EQUIVALENT• CORROSIVE RESISTANTDISPOSABLE AND CLEANABLELINE TYPE FILTER ELEMENTSThese all-nylon suction strainers are ideal for use wherestainless steel or other metal strainers might corrode orcontaminate your fluid. Such applications include water/seawater/de-ionized water, medical/pharmaceutical, generalindustrial, chemical, and coolant/lubricant. They are availablein nut or nipple sizes in flow rates to 3 GPM. The nut style isavailable in 5 pipe sizes, while the nipple is available in 3.Their unique construction, molded from nylon, offers theequivalent retention of 30 mesh woven wire.That low-cost construction also makes them economical,easy-to-use, and disposable, saving you time and money.HOW TO ORDER NYLON SUCTION STRAINERSSelect the desired specifications from the ordering tableand build an ordering code number, as shown in this sample:NYL - 3 - 1/2 - NUT - 30STYLE - GPM - NPT - CONNECTION - MESH1-3/82-1/41-3/82-1/41-3/82-1/41-3/82-1/4STYLE GPM NPT CONNECTION MESH(Pipe Size) (Nut or Nipple) (Screen Size)1/81/43/8 NutNYL 3 1/2 303/4NPTNPTNPTNPT3/81/2 Nipple3/43-5/84-5/163-5/84-5/163-5/85-5/163-5/85-5/161-15/161-15/161-15/161-15/16FLOW EZY OLD A B C O-RINGPART NO. FLOW EZY NO.PART NO.AN PART NO. AN-6235-1AAN-6235-1A-03G 9133-22 1-7/8 .391 53/64 2-012AN-6235-1A-10C 9133-11AN-6235-1A-25W 9133-05AN-6235-1A-40W 9133-04AN-6235-1A-74W 9133-02AN-6235-1A-149W 9133-01AN-6235-1A-238W 9133AN-6235-1A-590W 9133-30MAN PART NO. AN-6235-2AAN-6235-2A-03G 4-5/8 .641 1-1/8 2-11410C25W40W74W149W238W590WAN PART NO. AN-6235-3AAN-6235-3A-03G 6836-03G 3-7/16 .890 1-5/8 2-21210C 6836-10C10W 6836-10W25W 6836-25W40W 6836-40W74W 6836-74W149W 6836-149W238W 6836-238W590W 6836-590WAN PART NO. AN-6235-4AAN-6235-4A-03G 6927-03G 4-7/16 1.015 1-3/4 2-21410C 6927-10C05W 6928-05W10W 6928-10W25W 6928-25W40W 6928-40W74W 6928-74W149W 6928-149W238W 6928-238W590W 6928-30 MESHACO.D.BDIA.OPTIONALNITRILE (BUNA) SEALS INCLUDED10

TANK-MOUNTED STRAINERSA tank-mounted strainer (eithersuction or return) can be installedthrough a tank top by welding astandard bell reducer (coupling)over a hole cut in the top.A standpipe, threaded into thecoupling, need be only long enoughto stay below the lowest fluid levelencountered. The strainer may beremoved for servicing withoutdraining the tank.<strong>Flow</strong> <strong>Ezy</strong> tank-mounted strainersand diffusers install through theside wall, or through the tank topand into a standpipe. Either way,they can be removed through thehole in which they are mounted,and access to the tank interior isnot necessary. They’re made inthree styles: for suction straining,return-line straining, or return-linediffusion. Diffusers have no wirecloth elements; their function isto reduce foaming, tank noise,need for baffling plates, andpump cavitation caused by flowdisturbance at the pump inlet.Strainer elements are offered in30, 60, l00, or 200 mesh size.Bypass relief valves can besupplied, built in.These products most commonlyhave a male NPT, to mount tothe tank. A male SAE straightthreadis also offered. Severalmethods of connecting fluid linesexist, the most common beinginto a female NPT. (A femaleSAE straight-thread is alsooffered.) Hose connections,either beaded or barbed, areavailable too.There’s a wide choice ofmaterials of construction.The standard (and least costly)units have a cast iron bushing,steel support tube, and stainlesssteel wire cloth element. Alsooffered are models with forgedsteel bushings, or an all-welded,all stainless steel unit (no epoxy).A return-line strainer like thatshown (or a suction strainer or flowdiffuser) can be mounted througha tank wall.For ordering information, see next pages.Although designed for mountingthrough walls, these strainers canalso be adapted to in-line use.Using standard pipe fittings likethose shown, a “housing” for astrainer can be quickly assembled.11

TANK-MOUNTED STRAINERS DimensionsHOW TO ORDER - Select desired specifications from ordering table and build ordering code number, as shown in sample:SAMPLE: S - 25 - 60 - RV-5STYLE - GPM - MESH - VALVESTYLE CONSTRUCTION GPM(FLOW CAPACITY)MESH(SCREEN SIZE)VALVE(OPTIONAL)SUCTIONSSFSSASWSTIron construction, metal support tube, epoxy bondedForged steel bushings, metal support tube, epoxy bondedAll-stainless steel, all welded (no epoxy)Straight-thread steel bushing, metal tube, epoxy bonded4,5,10,15,25,50,1005,10,15,2530,60,100,200RV-3(3-psi bypass)RV-5(5-psi bypass)RETURNRRFSRASWRTIron bushings, metal support tube, epoxy bondedForged steel bushings, metal support tube, epoxy bondedAll-stainless steel, all welded (no epoxy)Straight-thread steel bushing, metal tube, epoxy bonded5,10,15,2519,33,54,94,200,46219,33,54,9430,60,100,200RV-15(15-psibypass)DIFFUSERDDFSDASWDTIron bushings, perforated metal, epoxy jointForged steel bushings, perforated metal, epoxy jointAll-stainless steel, all welded (no epoxy)Straight-thread steel bushing, perforated metal, epoxy joint20,34,55,95,209,46420,34,55,95(No wire meshelement)N/A<strong>Flow</strong> ratings are based on use of schedule 40 pipe.SUCTION (Style S)FOR PIPE LINE CONNECTIONBC(Male NPT)D(Female NPT)C(Male SAESt-Thread)D(Female SAESt-Thread)BC(Male NPT)D(Female NPT)ASTYLE S (stock item)STYLE SFS (Not stocked)SCREEN GPM A B C D E C D EAREA (in 2 ) (NPT) (NPT) (Approx.) (SAE Thd.) (SAE Thd.) (Approx.)CC4 4-1/4 13/16 (Male C NPT) 1-1/16-12 3/4-16 (Male C SAE 1B(Male NPT)St-Thread) (Male SAEB 34 5 4-1/4 1-1/32 1 1/2 D1-1/16 1-5/16-12 3/4-16 D 1St-Thread)65 10 6-3/4 1-11/32 1-1/4 3/4 (Female D1-1/4 NPT) 1-5/8-12 1-1/16-12 (Female D 1 SAE(Female NPT)St-Thread)86 15 7-3/16 1-21/32 1-1/2 1 1-5/16 1-7/8-12 1-5/16(Female1SAESt-Thread)125 25 8-1/4 A 2-1/32 2 1-1/4 E 1-5/16 2-1/2-12 1-5/8-12 E 1260 50 8 A 2-31/32 3 2 E 1-3/4 3-3/8-12 2-1/2-12 E 1315 G100 9-5/8 4 4 3 1-3/4EESTYLE ST(Not stocked)ASTYLE SASW(Not stocked)SCREEN GPM A B C D EAREA (in 2 ) (NPT) (NPT) (Approx.)C(Male C NPT)B 26 5 4-5/8 1-1/8 1 1/2 1-1/16(Male NPT)B 65 10 7-1/4 1-11/32 1-1/4 3/4 1-3/16 D(Female D NPT)68 15 7-1/2 1-21/32 1-1/2 1 1-1/4(Female NPT)100 25 8-5/8 1-7/8 2 1-1/4 1-1/2160 50 8-1/4 A 3-3/16 3 2 E 1-7/8AE275 100 10 4 4 3 2-1/8ERETURN (Style R)<strong>BB</strong>BGAAAEC(Male NPT)C(Male D NPT)(Female C NPT)D(Male NPT)(Female NPT)D(Female NPT)STYLE R (stock E item)STYLE RFS (Not stocked)ESTYLE RT E(Not stocked)St-Thread)C(Male D SAESt-Thread) (Female SAESt-Thread) CD(Male SAE(Female St-Thread) SAESt-Thread) D(Female SAESt-Thread)G SCREEN GPM A B C D E C D ECCAREA (in 2 ) (NPT) (NPT) (Approx.) (Male NPT) (SAE Thd.) (SAE Thd.) (Male (Approx.) SAEBSt-Thread)7/8 34 19 4-1/4 1-1/32 1 1/2 DC1-1/16 1-5/16-12 3/4-12 DC1(Female (Male NPT) NPT)(Female SAE1 65 33 6-3/4 1-11/32 1-1/4 3/4 1-1/4 1-5/8-12 1-1/16-12 (Male 1 SAESt-Thread)BSt-Thread)1-1/8 86 54 7-3/16 1-21/32 1-1/2 1 D1-5/16 1-7/8-12 1-5/16-12 D 11-1/4 125 94 A8-1/4 2-1/32 2 1-1/4 E (Female1-5/16NPT)2-1/2-12 1-5/8-12 E (Female 1 SAESt-Thread)1-1/2 260 G 200 8 2-31/32 3 2 1-3/4 3-3/8-12 2-1/2-12 12 315 462 9-5/8 A 4 4 E3 1-3/4EDIFFUSER (Style D)EEC(Male SAE<strong>BB</strong><strong>BB</strong>BAAA STYLE RASW(Not stocked)EEC(Male NPT)CD(Male NPT)(Female NPT)CD(Male NPT)(Female NPT)D(Female NPT)SCREEN GPM A B C D ECAREA (in 2 ) (NPT) (NPT) (Approx.)(Male NPT)26 19 4-5/8 7/8 1 1/2 1-1/16 D(Female C NPT)65 33 7-1/4 1-1/8 1-1/4 3/4 1-3/16 (Male NPT)68 54 7-1/2 1-3/8 1-1/2 1 1-1/4 D100 94 A8-5/8 1-5/8 2 1-1/4 E 1-1/2 (Female NPT)160 200 8-1/4 2-7/8 3 2 1-7/8275 462 A10 3-5/8 4 3 E 2-1//8EBC(Male NPT)D(Female NPT)C(Male SAESt-Thread)D(Female SAESt-Thread)BC(Male NPT)D(Female NPT)12AESTYLE D (Stock item)STYLE DFS (Not stocked)ESTYLE DT(Not stocked)PERF. OPEN GPM A B C D E C D EAREA (in 2 ) (NPT) (NPT) (Approx.) (SAE Thd.) (SAE Thd.) (Approx.)3.1 20 4-1/4 7/8 1 1/2 1-1/16 1-5/16-12 3/4-12 16.9 34 6-3/4 1-1/8 1-1/4 3/4 1-1/4 1-5/8-12 1-1/16-12 18.8 55 7-3/16 1-1/4 1-1/2 1 1-5/16 1-7/8-12 1-5/16-12 112.3 95 8-1/4 1-9/16 2 1-1/4 1-5/16 2-1/2-12 1-5/8-12 117 209 8 2-1/8 3 2 1-3/4 3-3/8-12 2-1/2-12 139 464 9-5/8 4 4 3 1-3/4ASTYLE DASW(Not stocked)PERF. OPEN GPM A B C D EAREA (in 2 ) (NPT) (NPT) (Approx.)3.1 20 4-5/8 7/8 1 1/2 1-1/166.9 34 7-1/4 1-1/8 1-1/4 3/4 1-3/168.8 55 7-1/2 1-1/4 1-1/2 1 1-1/412.3 95 8-5/8 1-9/16 2 1-1/4 1-1/221.1 209 8-1/4 2-7/8 3 2 1-7/833.2 464 10 3-5/8 4 3 2-1/8E

FLOW DIFFUSERSSTRAINER MAGNETS<strong>Flow</strong> diffusers are for hydraulic high-speed returnlines, to slow down fluids entering the reservoir.They help cure foaming problems and preventcavitation caused by flow disturbance at the pumpinlet. They allow greater freedom in reservoirdesign, and may even eliminate the need for tankbaffling plates. They also reduce reservoir noise.The unit is of all-steel welded construction, andmay be ordered with nut or nipple connector.HOW TO ORDERMODEL Length DiameterD-33 3-1/8 3-3/16D-33 Nipple 4-5/16D-54 5-3/8 3-3/16D-54 Nipple 6-9/16D-94 7-3/16 3-3/16D-94 Nipple 8-1/8D-127 8-13/16 4-1/8D-127 Nipple 9-3/4D-210 9-11/16 4-1/8D-210 Nipple 10-3/8D-300 12-11/16 5-1/4D-300 Nipple 13-1/16D-460 12-11/16 5-1/4D-460 Nipple 13-1/16D-700 18-1/4 8-1/4DIAMETERPERFORATIONS 240LENGTHFlex-Wrap Magnets make sump strainers workbetter. These flexible magnets wrap aroundstrainer elements to help catch tiny iron particleswhich might otherwise get through the mesh, thusimproving strainer performance. They are easyto install, easy to remove for cleaning, and easyto clean (just wipe with a cloth). They don't blockthe pleats of the strainer; they just touch the tops.Flex-Wrap Magnets are available in sizes foruse on strainer elements with:2-in. OD (3-gpm strainer),3-in. OD (5-, 10- & 20-gpm strainers),4-in. OD (30- & 50-gpm strainers),5-in. OD (75- & 100-gpm strainers),and 6, 8 and 10-in. OD (for Texas strainers).Many other sizes available. Call factory.RECOMMENDED USAGE ON FLOW EZYSTRAINERS IS (Order by OD):For Strainer ElementRecommendedOD (in.) GPM Number of Magnets2 3 13 5,10,20 24 30,50 25 75,100 46,8,10 Texas Strainer 4ENGINEERING DATAReturn Total Open Ratio<strong>Flow</strong> Connector Area of of AreaModel at 20 ft. Size Perforations Performations:No.* Per Sec.** NPT Each PIPEGPM.093" Dia.D-33 33 3/4 5 Sq. In. 8.8:1D-54 54 1 11 Sq. In. 13:1D-94 94 1-1/4 16 Sq. In. 11:1D-127 127 1-1/2 26 Sq. In. 13:1D-210 210 2 28 Sq. In. 8.3:1D-300 300 2-1/2 48 Sq. In. 10:1D-460 460 3 48 Sq. In. 6.5:1D-700 700 4 & 6 SPECIAL ORDER ONLY*When ordering a NIPPLE connection, add word NIPPLE to model number**Returning fluid speed, based on use of Schedule 40 pipe.14

PIPE-MOUNTED SUCTION SCREENSMESH SIZE TABLEU.S. MESH INCHES MICRONS4 .187 47606 .132 33608 .0937 238010 .0787 200020 .0331 84130 .0232 59540 .0165 42060/30* .0098 250100/30* .0059 149200/30* .0029 74Suction screens can be used for strainingoil, chemical liquids, and water. They will notrust. They’re made of tough glass-filled nylonresins with stainless steel wire cloth elements.With male or female NPT connectors, tothread into or onto pipe. There are ten wiremesh sizes to choose from. The finer 60-,100-, and 200-mesh size screens are backedup with a heavier 30-mesh inner support.*The "30" stands for the mesh size of the support screen.HOW TO ORDERNUT STYLE STRAINERSPART NPT SCREEN DIMENSIONSNO. (Pipe AREASize) (Sq. in.) A B C HEXF-01 1/8 3.1 1-1/2 1-5/8 1 1-3/8F-02 1/4F-03 3/8F-04 1/2F-1 1/8 6.5 1-1/2 2-1/4 1-1/2 1-3/8F-2 1/4F-3 3/8F-4 1/2F-5 3/4F-6 3/4 14.75 2-1/8 3-3/16 2-1/2 1-3/8F-8 1 1-5/8F-10 1-1/4 2F-12 1-1/2 27.5 2-5/8 4-3/16 3-1/2 2-1/4F-16 2 2-3/4F-20 2-1/2 46 3-1/2 5-3/16 4-1/2 3-1/4F-24 3 4NIPPLE STYLE STRAINERSPART NPT SCREEN DIMENSIONSNO. (Pipe AREASize) A B CM3 3/8 6.5 2-1/2 2-1/4 1-1/2M4 1/2M6 3/4M8 1 11.2 2-1/2 3 2-1/8M16 2 27.5 4-1/4 4-3/16 3-1/2M20 2-1/2 2-7/8*M24 3 46 4-5/8 5-3/16 4-1/2* No hex between nipple and strainer on this partChoose a part number fromthe nut or nipple table andadd the mesh size desiredfrom the mesh size tablelocated above.Example:A 2-in. nut-style strainer is partnumber F-16, and ordering itwith a 20-mesh wire screenwould add “20” to the partnumber, making it F-16-20.CCCCAAAA<strong>BB</strong><strong>BB</strong>ALL STAINLESS STEELSUCTION SCREENPerfect for straining paint,petroleum based fluids,chemical liquids, orwater. Not affected bytemperature, will not strip,pull loose, or crack.2-1/4" OD x 1-1/2" tallHOW TO ORDER:Example: F6 - 30/8 - SSModel No.1/2" NPT = F43/4" NPT = F61" NPT = F8Mesh Size:16 over 8 mesh = 16/830 over 8 mesh = 30/860 over 8 mesh = 60/8Stainless Steel = SS15

TANK FILLER-BREATHERSThese provide filler ports forhydraulic power unit tanks orother liquid reservoirs. Liquidsare strained as they are addedto the tank and it lets the tankbreathe filtered air.The 30-mesh filler screenremoves dirt and debris fromliquids as they enter thesystems. The breather capfilters the air, trapping airbornedirt down to 40- or 10-micronlevels. It permits air passageat up to 25 scfm. Mountinghardware, gaskets, andtemplates are supplied.ACCESSORIESPERFORATED INNER GUARD:Protects strainer basket againstpuncture. Four sizes (3", 6", 8" and13") to match basket depths.MAGNET AND POST: Attaches tobottom of basket, removes tiny ironparticles which can sift through thescreen. Impervious to hydraulic fluid.Three sizes (3", 6", and 8").DIPSTICK: Attaches to cap. Can bemarked to order: FULL, ADD, etc.Supplied in lengths (3", 6", 8" and13"). Eliminates safety chain. Ifchain is wanted, it must be ordered.The standard filler cap can beordered with these modifications:Padlock adapted. To help preventtampering, the cap and mount canhave welded lugs to allow use of apadlock. Specify “padlock adapted”.Stainless steel. Stainless capsand all-stainless units are available.Specify “stainless cap” or “allstainless” (AB only).STEEL TOP-MOUNTINGUNITSIf funnels are used for filling,it is recommended that the screenbasket be ordered at least6-inches deep, to preventaccidental puncturing.Perforated metal innerguards may be ordered also,to prevent damage to the screen.To help prevent tank-top dirt fromplugging up the air filter you canorder a ‘high-neck’ model. It putsthe air filter 3 inches above the tanktop. A ‘grip’ cap is another option:it is a larger, nickel-plated filler cupwith curved indentations to providea better gripping surface. Ideal foroutdoor or oily environments.1-11/16HOW TO ORDER TOP-MOUNTED UNITSSTD.CAPStandard3,6,8,or 13Select the desired specifications from the ordering table andbuild an ordering code number, as shown in this example:High-NeckAB - 1000 - 6 - HN - G - DS-6 - M8 - LL - BPCCAP ELEMENT BASKET NECK GUARD DIP Magnet Lockable(omit if not wanted)CAP ELEMENT BASKET NECK InneR DIP MAGNET Lock BLACKType (Micron) Depth (in.) Height GUARD Stick**** and POST Lugs POWDERCOATEDAB* 1000 3 No Symbol No symbol No Symbol No Symbol LL BPC(Std.) (40) 6 (Std.) (no guard) (No stick) (no magnet)8 ABGABG** 1010 13 HN*** G DS-3*** M3 ABGP(Grip (10) (High (guard) (3-in.) (3-in. post) (only)type) neck) DS-6***(6-in.) M6ABNV DS-8*** (6-in. post)(Non-(8-in.)vented) DS-13*** M8(13-in.) (8-in. post)2-5/161-7/83-1/42-7/811/64 DRILLSIX PLACES*Stainless steel available on AB only. **ABG comes nickle plated or black powder coated.***No chain unless specifically ordered. ****Dip stick markings available (minimum order and extra charge).GRIPCAP2-1/1641-7/83-1/44-3/83,6,8,or 13MagnetFiller-breathers withstandard neck heightscome with safety chainsunless ordered without.Basket with innerguard and magnet.16

TANK FILLER-BREATHERS2-5/162-7/811/64 DRILLSIX PLACESABRCAPABGRCAPREMOVABLEBASKET UNITS1-11/162-1/164HIGHNECk4-3/8The strainer baskets in these units pullout creating an easy point of entry intoa hydraulic or lube oil reservoir for asuction hose. Allows easy removal of fluid.They are available with the same choice inaccessories as the standard top-mountingunits have. It’s also easier to clean thebasket of any dirt accumulation.AA1-5/163-1/41-5/163-1/4HOW TO ORDER REMOVABLE BASKET UNITSSelect the desired specifications from the ordering table andbuild an ordering code number, as shown in this example:ABR - 1000 - 6 - HN - DS-6 - LL - BPCCAP ELEMENT BASKET NECK DIP Lockable PowderCoated(R = Removable) (omit if not wanted)CAP ELEMENT BASKET(A) NECK DIP Lock BlackType (Micron) Depth (in.) Height Stick*** Lugs PowderCoatedABR* 1000 3 No Symbol No Symbol LL BPC(Std.) (40) 6 (Std.) (No stick)8 (ABGABGR 1010 13 HN** DS-3** style(Grip (10) (High (3-in.) only)type) neck) DS-6**(6-in.)DS-8**ABGPR(8-in.)DS-13**(13-in.)*Stainless steel available on ABR only. **No chain unless specifically ordered.***Dip stick markings available (minimum order and extra charge).Removablebasket unitLockable cap17

TANK FILLER-BREATHERSALL-NYLON TOP-MOUNTING UNITSThis is an alternative to the traditional metal tankfiller. It is made entirely of injection-molded,glass-filled nylon, which provides an attractive,tough, non-rusting product. A strainer basket with30-mesh equivalent openings is provided.It will fit into the same size hole as the metal units,and they share the same screw hole pattern.Nylon breathers are offered only with a 10-micronrated air filter, and in only one basket depth.Mounting hardware supplied. (Stainless steelscrews and dipsticks are available.)TO ORDER, SPECIFYStandard modelMODEL NO. NAB-1010-4Weatherproof modelMODEL NO. NABG-1010-4-WP*Anti-Slosh model (See <strong>Catalog</strong> DCK)MODEL NO. NAB-1010-4-AS*Not stockedFor molded nylon parts made to your specs, call<strong>Flow</strong> <strong>Ezy</strong>. Baskets also available separately.1-1/22-7/163-7/8UNITS FOR PRESSURIZED TANKSThese units provide air flow at 25 scfm todisplace liquid at the rate of 190 gpm. They havea pressure rating of 5 psi (10 psi optional). It isavailable in either the standard mount or withthe optional “High-neck” mount, which keeps thebottom of the air filter three inches above the tanktop. The four-inch deep strainer basket is made ofnylon, and has openings equivalent to 30-mesh.The grip-type cap is made of plated steel, andhas a 10 or 40-micron air filter.A safety chain is supplied on the standard model;if desired on the high neck model it must bespecified.To help prevent tampering the cap and mountcan have welded lugs to allow use of a padlock.Specify "padlock adapted".TO ORDER, SPECIFY2-5/162-7/811/64 DRILLSIX PLACESStandard modelNO. ABGP-1000-4(40-micron)NO. ABGP-1010-4(10-micron)High-neck modelNO. ABGP-1000-4-HN(40-micron)NO. ABGP-1010-4-HN(10-micron)Available with lockablecap, add "-LL" at endof model no.STANDARD2-1/4HIGH NECK4-5/841-7/83-1/41-15/163-1/4Nylon weatherproof capGrip type cap18

SIDE-MOUNTING UNITS2 223-1/22 31/43/8DRILL 7 HOLES THRU 9/32 DIA.3-7/83-1/2566-5/16Where top surfaces are notavailable for locating a fillerport, this unit mounts on verticaltank walls. The housing is tough,glass-reinforced nylon. It’s onlyavailable with a 3-in. deep basket(and optional inner guard).The only other options are the3-in. dipstick, the lockablecap, and powder coated cap.AGCHHOW TO ORDER SIDE-MOUNTED UNITSSelect the desired specifications from the ordering table andbuild an ordering code number, K as shown in this example:B DE FAM - 1100 - 3 - G - LL - DS - BPCCAP - ELEMENT - BASKET - GUARD - Lockable - Dipstick - BlackPowderCoatedL M (SPOTFACE) J(omit if not wanted)CAP ELEMENT BASKET Inner Lock Dipstick* Black PowderType (Micron) Depth (in.) GUARD Lugs Coated CapAM 1100 3 no symbol LL DS BPC(std) (40) (only) (no guard)AMG 1110 G(grip (10) (guard)type)*No chain unless specifically ordered.Black powder coatedlockable CapShown withgrip type cap19

TANK BREATHERSSTANDARD UNITSThese devices ensure a free flow of airinto hydraulic tanks or similar containers, whilestopping the entry of airborne contaminants.Both 40-micron and 10-micron rated elements areoffered in most models. They permit air passageat up to 25 scfm. They have NPT bases.BF Models. Available in all-steel or nylon-baseconstruction. The nylon-base unit is more thanstrong-enough, and it costs less.BFG MODELS. Available with a steelplated grip cap and steel base in 3/4".Both 10 and 40 micron available.ORDER BY PART NUMBERTYPE FILTER NPT MODEL(Micron) (In.) NUMBER40 3/8 BF-2041Nylon 1/2 BF-2042Base 3/4 BF-204310 3/8 BF-20111/2 BF-20123/4 BF-2013Steel 40 1/4 BF-2140***Base 40 3/4 BF-214340 3/4 BFG-214340 3/4 BFGP-2143*10 3/4 BF-2113*10 3/4 BFG-2113*10 3/4 BFGP-2113*All 10 1/4 NBF-2010***Nylon** 3/8 NBF-20111/2 NBF-20123/4 NBF-20131 NBF-20141-1/4 NBF-20151-1/2 NBF-2016NBF Models. These are of all-nylonconstruction, and have larger than usualthreaded bases, up to 1-1/2 in. NPT.They can be used in ports large enough toserve also as filling openings. Nylon dipsticksare optional; just add “dipstick” to the modelnumber. A weatherproof cap is another option;add “WP” at end of model number. For splashproof cap; add "SP" at end of model number.PRESSURIZED TANK BREATHERAllows air flow to 30 cfm and available ineither 10 or 40 micron with a 5 psi relief valvesetting (3 psi and 10 psi available with specialorder). Available in 3/4" NPT with a steelbase and a grip cap made of plated steel.1-13/16BF MODEL (1/4 NPT)2-9/162-1/831-1/23BFG and BFGP STYLES3-3/82-5/162-1/8* 3 and 5 psi in stock. 10 psi is not stock.** Add "WP" at end of model no. for weatherproof top.Add "SP" at end of model no. for splash proof top.***Dipstick not available.BF MODEL (3/4 NPT)NBF MODELNylon BaseSplash proof capSteel BaseAll nylon withoptional dipstickNylon weatherproof cap20

TANK BREATHERSSPIN-ON FILTER ELEMENTSMAKE BIG TANK BREATHERSGet better filtration of air entering your larger hydraulictanks, plus much longer filter life, by utilizing 3-, 10-, or25-micron spin-on hydraulic filters as great big tankbreathers (TBAB also available at 149-micron).We offer a choice of three simple adapters to do the job:• They all have nipples with straight threads on oneend to attach to the filter can.• TBA has NPT threads on the other end to gointo a flange welded to the tank top.• TBAF has an integral half-coupling for mounting.• TBAB has a bayonet (gas cap) for mounting.We sell you black-oxide steel adapters and highqualityspin-on elements at low, low prices.ORDER BY PART NUMBERSPIN-ON FILTER ELEMENTSMicron Part F G H J KRating No. NPT (approx)3 FEE-30-3 TBA-12 3/4 5-1/4 7-1/4 3-11/16FEE-51-3 TBA-20 1-1/4 6-7/8 9 5-1/1610 FEE-7-10 TBA-08 1/2 3-3/8 5-1/8 3-1/16FEE-30-10 TBA-12 3/4 5-1/4 7-1/4 3-11/16FEE-51-10 TBA-20 1-1/4 6-7/8 9 5-1/1625 FEE-7-25 TBA-08 1/2 3-3/8 5-1/8 3-1/16FEE-30-25 TBA-12 3/4 5-1/4 7-1/4 3-11/16FEE-51-25 TBA-20 1-1/4 6-7/8 9 5-1/16TANK BREATHER ADAPTERS - ThreadedPart No. A B C (NPT) D ETBA-08 2-3/16 7/16 1/2 3/4-16 UNF 2-214TBA-12 2-1/2 1/2 3/4 1-12 UNF-2A 2-212TBA-20 3 1/2 1-1/4 1-1/2-16 UN-2A 2-220JHDEBUNA NO RINGCJHDEBUNA NO RINGCTBABTBADkABkADEBUNA NO RINGDEBUNA NO RINGBSPIN-ONFILTER ELEMENTSPIN-ONFILTER ELEMENTFTANk BREATHERADAPTERGFFLANGETANk BREATHERWELDED TO TANkADAPTERGHYDRAULICFLANGE RESERVOIRWELDED TO TANkHYDRAULICRESERVOIRDEBUNA NO RINGBCTBAFABCTBAFBAATANK BREATHER ADAPTERS - With FlangePart No. A B C D ETBAF-08 2-3/16 7/16 3-1/4 3/4-16 UNF 2-214TBAF-12 2-1/2 1/2 3-1/4 1-12 UNF-2A 2-212TBAF-20 3 1/2 3-1/4 1-1/2-16 UN-2A 2-220TANK BREATHER ADAPTERS - Bayonet CapEBUNA NO RINGCTBABCTBABAPart No. A B C D ETBAB-08 2 7/16 2-1/2 3/4-16 UNF 2-214TBAB-12 2 9/16 2-1/2 1-12 UNF-2A 2-212TBAB-20 2-3/8 7/16 2-1/2 1-1/2-16 UN-2A 2-220TBAB BayonetSpin-On filter element21

GIANT TANK BREATHERSThese over-sized units stop airborne dirt from enteringtanks as liquid is removed. They provide clean, filteredair fast to replace liquids going out at high rates - up tohundreds of gallons per minute.Giant tank breathers screw into NPT ports up to 3 inchesin size. The threaded base is of nylon, which is strong,lightweight, and seals well against metal. (4-inchmodels with steel bases are also available; minimumorder is twelve.) The strong, steel coverprotects the filter elements.A wide selection of filter elements is offered. They arepleated to increase surface area and dirt holding capacity,and are supported by coarse wire mesh. Elements rated40 micron and finer are made of synthetic or cellulose(paper) material. Those rated 74 and 149 microns are ofstainless steel wire mesh. Elements are easily replacedand replacements are always available.HOW TO ORDERSelect the style number and theelement micron-rating you wantand combine them.Example: Style BF-2017 pluselement 10C would be orderedas BF-2017-10CSIZE STYLE MICRONNPT (in.) NO. RATING†2 BF-2017 10C2-1/2 BF-2018 20C3 BF-201940A74W4* BF-2020 149W* Metal base†“C” means cellulose, “A” meanssynthetic, and “W” means wire cloth.DIMENSIONS (inches)STEEL SHELLREPLACEMENT ELEMENTSStyle A <strong>BB</strong>F-2017 5-13/16 6-1/2BF-2018 7 8-1/4BF-2019 7 8-1/4BF-2020 7 8-1/4ELEMENTHARDWARE ISPLATED STEELNYLON BASEADIA.BMicron For Style For StyleRating BF-2017 BF-2018, 9, & 20Part No. Part No.10C 7827 780720C 7827-01 7807-0140A 7827-02 7807-0274W 7828 7826149W 7828-01 7826-0122

BACK-PRESSURE INDUCERSJET MUFFLERSThese devices eliminate the need for expensivecomponents to induce hydraulic back pressure, aswell as the misapplication of other components,such as check valves, for the same purpose.When installed in a heat-exchange bypass line,the inducer will limit the pressure of the fluid flowinginto the heat exchanger. They can be usedto maintain a required return line back-pressure.Many other uses are possible.HOW TO ORDERPI - 8 - 12 - 15MODEL - FEMALE - MALE - VALVENPT NPT RATINGSTYLE FEMALE MALE VALVENPT NPT RATINGPI 2 (1/4) 8 (1)34 (1/2) (3 PSI)6 (3/4) 10 (1-1/4)58 (1) 12 (1-1/2) (5 PSI)10 (1-1/4) 16 (2)1512 (1-1/2) (15 PSI)16 (2) 24 (3)Standard size combinations are those shown side-by-side(6-10, 8-12, 10-16, 16-24). Any feasible size combinationsmay be ordered, but they’re not stocked (4-12, 8-16, etc).DIMENSIONS (approximate)MALETHREAD A B C1 1-1/2 1 3/41-1/4 1-13/16 1-1/4 1-1/81-1/2 2 1-5/16 1-3/82 2-9/16 1-5/16 1-1/43 3-1/4 1-5/8 1-1/4PRESSURE DROP (approximate)LINE SIZE (in.) 3/4 1 1-1/4 2ABC• 1/8 to 1-inch NPT• Superior Noise Reduction• Easily Disassembled• Fail Safe prevents excessiveback pressure buildup• Minimal Pressure Drop• Rugged Plastic ConstructionJet Pneumatic Exhaust Mufflers providesuperior exhaust noise control and areavailable in two patented configurations,the TM and SLM Series.They use a multi-layered,wire mesh element thatis impervious to solvents,and easily removed forcleaning.DIMENSIONS (inches)MODEL PIPE SIZE DIAMETER LENGTHTM-1 1/8 1.62 1.76TM-2 1/4 1.62 1.76TM-3 3/8 2 2.83TM-4 1/2 2 2.94TM-6 3/4 2.92 4.15TM-8 1 2.92 4.38SLM-1 1/8 .95 2.35SLM-2 1/4 .95 2.48SLM-3 3/8 1.34 3.55SLM-4 1/2 1.34 3.68SLM-6 3/4 1.90 5.60SLM-8 1 1.90 5.85HOW TO ORDERLENGTHDIAMETERVELOCITY (fpsthru schd. 40 pipe) 10 20 10 20 10 20 10 20PIPE SIZENPT (in.)MODELFLOW RATE (gpm) 17 34 27 54 47 94 105 210SPRING RATING PRESSURE DROPS (psi)(crackingpressure, psi) 3 14 39 7 16 5 23 6 235 16 41 9 18 6 25 8 2515 45 70 17 30 14 40 26 601/8 TM-1 SLM-11/4 TM-2 SLM-23/8 TM-3 SLM-31/2 TM-4 SLM-43/4 TM-6 SLM-61 TM-8 SLM-8REQUIREDVOICELEVELVery LoudRaisedNormal100807060200 Hz 500OPEN OPEN LINE LINELINE WITHJET MUFFLER1000 2000 500023

SPIN-ON FILTERS• FLOWS TO 60 GPM• PRESSURES TO 150 psi• STANDARD CAN THREADS• DIE-CAST ALUMINUM HEADSThese are industry-standardfilters; the replacement elementswill fit the heads of other majormanufacturers (and vice versa).The smaller model FEF-30 canswill interchange with those ofU.S. manufacturers, and thelarger Model FEF-51 cans willinterchange with those of U.S.and some European suppliers.FILTER MODELFEF-7 FEF-30 FEF-51A 3.05 3.75 5.15B 1.29 2.87 2.58C 4.5 7.28 9.56D .5 .63 1.5G 3.05 3.86 5.04H 1,50 1.50 1.87L 1/4-20 1/4-20 5/16-18M 1.12 1.52 2.40Weight 13 oz 1.75 lb 4.0 lbqMAGPRESSURE DROP (PSI)PRESSURE DROP (PSI)Typical FEF-30 pressure ASSEMBLY drop through cleanFEF-51filterASSEMBLYassembly with oil viscosity of 150 SUS3025201510525HOW 03 TO ORDER COMPLETE FILTERS2025 PSI BY-PASS 1025 PSI BY-PASS 03152510102550 5 10 15 20 25 30FLOW (GPM)FEF-51 ASSEMBLY302 MOUNTING25HOLES L20H25 PSI BY-PASS FEF 03151010PRESSURE DROP (PSI)201510MODEL FEF-51Element area 950 sq. in.<strong>Flow</strong>s up to 60 GPM (return)B50 2 4 6 8 10518 PSI BY-PASSFEF-7 ASSEMBLY10FLOW (GPM)25Cellulose0 10 20 30 40 50 60FLOW (GPM)CREMOVALCLEARANCEDPRESSURE DROP (PSI)PRESSURE DROP (PSI)PRESSURE DROP (PSI)201510530252015105FEF-30 ASSEMBLY0310250 5 10 15 20 25 30FLOW (GPM)3018 PSI BY-PASS0 2 4 6 8 1025 PSI BY-PASS10FLOW (GPM)25Cellulose0 10 20 30 40 50 60FLOW (GPM)HOW TO ORDER REPLACEMENT ELEMENTSPRESSURE DROP (PSI)PRESSURE DROP (PSI)FEE - 30 - 10STYLE - SIZE - ELEMENT30252015105FEF-30 ASSEMBLY0310250 5 10 15 20 25 30FLOW (GPM)3025201510525 PSI BY-PASSFEF-51 ASSEMBLY25 PSI BY-PASS0310250 10 20 30 40 50 60FLOW (GPM)Select the desired specifications from the ordering table andbuild an ordering code number, as shown in this sample:FEF - 30 - 12 - 10 - RV25STYLE - SIZE - PORT - ELEMENT - VALVESTYLE SIZE PORTS ELEMENT BYPASSVALVE7 04 (1/4 NPT)RV-25(25 PSI)06 (3/8 NPT)03 (3 micron)* size 30-5130 12 (3/4 NPT) 10 (10 micron)25 12S (1-1/16-12 SAE) 25 ( 25 micron)51 20 (1-1/4 NPT)24 (1-1/2 NPT)20S (1-5/8-12 SAE)*Not available on FEF-7, bypass for FEF-7 is located inside element.STYLE SIZE ELEMENT ELEMENTTHREAD7 *03 (3 micron) (7) 3/4-16 UNFFEE 30 10 (10 micron) (30) 1-12 UNF51 25 (25 micron) (51) 1-1/2-16 UNF**100 (100 mesh)RV-18(18 PSI)size 7*0no RVSelect the desired specifications from the ordering table andbuild an ordering code number, as shown in this sample:MODEL FEF-7Element area 117 sq. in.<strong>Flow</strong>s up to 7 GPM (return)qqMODEL FEF-30Element area 510 sq. in.<strong>Flow</strong>s up to 25 GPM (return)*Not available on FEE 7. **Available in FEE 30, 51 onlyHOW TO ORDER SPIN-ON HEADSSelect the desired specifications from the ordering table andbuild an ordering code number, as shown in this sample:FEH - 30 - 12 - RV25STYLE - SIZE - PORT - VALVESTYLE SIZE PORTS BYPASSVALVEFEH7 04 (1/4 NPT)06 (3/8 NPT)30 12 (3/4 NPT)16 (1-1/16-12 SAE)51 20 (1-1/4 NPT)24 (1-1/2 NPT)20S (1-5/8-12 SAE)*Bypass for FEH-7 is located inside element.RV-25(25 PSI)size 30-51RV-18(18 PSI)size 7*0no RV24

REUSABLE MAGNETSREPLACEMENT LUBE FILTERSFor use with Spin On filtersThe Bear Trap line of reusable filtermagnets are designed to remove ferrousmetal particles from hydraulic fluids, oil,fuel, coolant water and transmission fluids.Removes particles the filter doesn’t catch.Prevents downstream system damageby trapping metal particles in filter. Whenchanging the element, after removing fromthe system, remove the magnet from the“can” and attach it to the new element.For use with all brands of disposable filtersincluding those used on domestic andforeign motor vehicle engines, racingengines, diesel engines, transmissions,marine engines, motorcycle engines,hydraulic systems, fuel filters, andcoolant filters.Two sizes available - BT500 (2-1/4" sq.)and BT800 (3" x 6").This high-quality, in-line lubricant filter replaces units byPurolator, Cincinnati Milacron, and Danly, at substantialsavings. It finds wide application in filtering lubricant andcoolant on machine tools, and for many other tasks.The sealed metal canister contains a high-density, purecellulose filter element with over 400 square inches offiltering area. Standard element is rated for 10 micron.MANUFACTURER'S EQUIVALENT PART NUMBERSORDERPORT SIZE Cincinnati Danly FLOW EZYNPT Purolator Milacron Machine NO.1/4 L-12 219666 58-32-63043 FL-12215606831043/8 L-15 222148 FL-152461666831571/2 L-14 225470 58-32-630 FL-14227956683140PORTSIZE LENGTH PARTNPT IN. NO.1/4 5-7/8 FL-123/8 6-3/8 FL-151/2 6-5/16 FL-14PORTPORT4-1/44-3/425

300 PSI INLINE FILTERSWe have the highest quality materials, competitivepricing, and a huge inventory with overnight shippingavailable. There are more models available thanlisted here, call for a Motorsport catalog.Model ILAHOW TO ORDERSelect the desired specifications from the ordering tableand build an ordering code number, as shown in this sample:MODELREPLACEMENTCODESCREENS4ILA - 03 - 74 - F3 - RD 8286-02MODEL - SIZE - MICRON - SEALS - COLOR PART NO.MODEL CONNECTION MICRON SEALS COLOR PARTNUMBER SIZE SIZE (MICRON)ILA 02 238 No Symbol RD 6180-01 (238)(1/4-in.NPT) 149 Buna N Red 6180-05 (149)6T 74 6180-02 (74)(3/8-in.TUBE) 40 6180-03 (40)25 F3 BK 6180-09 (25)10 Viton Black 6180-10 (10)4ILA 02 595 BL 8286-30 (595)(1/4-in.NPT) 238 Blue 8286 (238)03 149 8286-01 (149)(3/8-in.NPT) 74 8286-02 (74)04 63 8286-03 (63)(1/2-in.NPT) 40 8286-04 (40)25 8286-05 (25)10 8286-10W (10)14ILA 04 595 8731-30 (595)(1/2-in.NPT) 238 8731 (238)06 149 8731-01 (149)(3/4-in.NPT) 74 8731-02 (74)08 63 8731-03 (63)(1-in.NPT) 40 8731-04 (40)25 8731-05 (25)10 8731-25 (10W)10C 8731-11 (10C)5C 8731-20 (5C)08G 8731-23 (08G)03G 8731-22 (03G)Pressure Rating: 300 PSIHousing Material: Anodized AluminumColors Available: Black, Blue, RedPleated Screen:<strong>Flow</strong> Rate:Filtration Area:Weight:Dimensions:Pleated Screen:<strong>Flow</strong> Rate:Filtration Area:Weight:Dimensions:Pleated Screen:<strong>Flow</strong> Rate:Filtration Area:Weight:Dimensions:Stainless SteelUp to 2 GPM1 Square Inch3 Ounces1/4 NPT: 1.75 x 1-in.3/8-in. Tube Size 6:2.88 x 1-in.Stainless SteelUp to 4 GPM20 Square Inches6.6 Ounces4-21/32 x 1-1/2-in.Microglass, Cellulose,Stainless Steel(Stainless SteelElements)Up to 14 GPM60 Square Inches1 Pound 2 Ounces7-25/32 x 2-1/8-in.Model 4ILAMOUNTING CLAMPSClamps are "tailor made" for in-line filters. Made ofstainless steel, with thermoplastic elastomer bushingstough enough to withstand temperatures up to 300°F.ORDER BY PART NUMBERModel 14ILAClampsShown onPage 28MODELNUMBER4ILAI4ILAPARTNUMBER024M028-SS034M040-SS26

FLOWLOW-COST IN-LINE FILTERS7050 10L1"Hex 1-9/16IN5-1/4" (Size 04 & 06)4-1/2" (Size 02, 03 & 035)View ShowingWire ClothOUT 2-1/2 O.D.FOR 8 GPMThe 7050 In-<strong>Line</strong> Filter israted at 8 gpm. Stainlesssteel wire cloth elements arecleanable by backflushing.1/4" NPT PortsBoth Ends8 GPMWeldedHOW TO ORDER - 10 GPMHOW TO ORDER - 8 GPMSTYLEELEMENT7050 01 238 Micron02 74 Micron03 40 Micron05 149 Micron09 25 Micron10 10 Micron10 GPMSelect the desired specifications from the ordering table andbuild an ordering code number, as shown in this sample:10L - 03 - 595 - RV-5 - M - CSSTYLE - NPT - ELEMENT - VALVE - MAGNETS - MATERIAL(omit if not wanted)FOR 10 GPMThe 10L In-<strong>Line</strong> Filter israted at 10 gpm (suction),200 psi operating pressure,these filters are used onlubrication and hydraulicsystems. Stainless steelelements are cleanable bybackflushing. Syntheticdepth-type elements arefor throwaway use, andgive finer filtration.Housings are sealedcanisters of carbon steel orstainless steel and contain50 square inches of elementover an inner support tube.Female NPT fittings areat both inlet and outlet.Options available areintegral bypass valvesand magnetic bands.STYLE NPT ELEMENT VALVE MAGNETS MATERIAL(Pipe) (Mesh or (Optional) (Optional)Micron)10L 02 Stainless RV-3 M CS(1/4) Wire: (3-psi) Carbon03 585 Steel(3/8) 238 RV-504 149 (5-psi) SS*(1/2) 74 Stainless06 40 RV-15(3/4) 25 (15-psi)03S Synthetic:(3/4-16) 15A (micron)40A (micron)*Available in 06 size onlyStyle 10LStyle 705027

1500 and 3000-PSI IN-LINE FILTERSFor 238, 149 and 74..75 (1.5 IN. Hg) pressure dropat 150 SUS viscosity fluid.6IL rated at 5 GPM (suction).15IL rated at 15 GPM (suction).These filters can also be usedfor higher return flows. Herehigher pressure drops (to 350psi) can usually be tolerated andfiner micron ratings are possibledepending on element pore sizeand fluid viscosity. Their sturdymachined-aluminum, steel, orstainless steel housings givethem the strength to be pressurerated at 1500 or 3000 psi.These units use pleatedelements made from eitherstainless steel wire cloth orcellulose (paper), with aperforated metal support tubeinside. These elements canbe easily removed for cleaningor replacement. (They can notbe cleaned by backflushingwhile in the housing.)REPLACEMENT ELEMENTS 350 PSIDMICRON 6IL 15ILRATING PART PARTNO. NO.REINFORCED ∆P ELEMENTS595 8504-595 8560-595238 8504 8560149 8504-01 8560-0174 8504-02 8560-0240 8504-04 8560-0425 8504-05 8560-0510W 8286-10W05C 8504-20 8560-2010C 8504-11 8560-1103G 8504-22 8560-2208G 8504-23 8560-226IL 15ILA 4-15/16 6-5/16B 1-3/8 2C 1-5/8 2-3/8D 1-1/2 2-1/8HOW TO ORDERBSelect the desired specifications from the ordering table andbuild an ordering code number, as shown in this sample:6ILA - 03 - 74 - F3 - USTYLE PORTS ELEMENT SEALS BRACKET(omit if not wanted)STYLE PORTS ELEMENT† SEALS BRACKETNPT SAE (Micron)6ILA 03 03S Stainless wire: no symbol U(Aluminum, (3/8) (3/4-16) 595 (Buna N)1500 psi) 04 (UNF-2B) 2386ILS (1/2) 04S 149(Steel, (7/8-14) 74 F33000 psi) 40 Viton6ILSS 25(Stainless 10*Steel,3000 psi)15ILA 06 06S(Aluminum, (3/4) (1-1/16-12) Cellulose:1500 psi) 08 (UNE-2B) 5C15ILS (1) 08S 10C(Steel, (1-5/16-12) Micro-glass:3000 psi) (UNF-2B) 03G15ILSS08G(StainlessSteel,3000 psi)†Other element ratings available on requestA*Available on 6IL only.CD6IL & 15IL U-BRACKETSTO FIT6ILA & 6ILS6ILSS15ILA & 15ILS15ILSSFLOW EZY NO.026M030026M030-SS038M044038M044-SSShown with optional U-Bracket28

CARTRIDGE FILTER HOUSINGThis design has been a standard in theindustry for over 40 years. The housing isavailable in either carbon steel or stainlesssteel. Maximum operating pressure is 250 psiand standard operating temperature is 275°F.This housing is available with 1" nptconnections only.DESIGN FEATURES• Designed for industrial and commercialfiltration applications• Heavy duty construction for durability• Offered in carbon steel or 304 stainless steel• Simple nut and bolt design for quickcartridge change outs• In-line fittings for easy installation• Knife edge seal at both cartridge endsto eliminate bypass• Designed for double open end cartridges• 1" npt pipe size standard• 1/8" npt drain port on bottom of housingTYPES OF CARTRIDGES AVAILABLE• <strong>Flow</strong> <strong>Ezy</strong>'s all stainless steel industrialprocess cartridges• <strong>Flow</strong> <strong>Ezy</strong>'s A2 model fabric wound9-7/8" cartridges• <strong>Flow</strong> <strong>Ezy</strong>'s meltblown 9-7/8" cartridges• Any other 9-7/8" double open end cartridgewith an ID of 1-1/8" and an OD of nolarger than 3"HOW TO ORDEROrder by model number:Order Cartridgeson pages30, 31, and 32MODELNUMBERFAC788FAS788DESCRIPTIONCarbon steel304 stainless steel29

MELTBLOWN CARTRIDGESMeltblown nonwovens are highly engineeredfabrics made of fine synthetic fibers thathave been thermally bonded to form a webstructure. Filtration is the fastest growing enduse market for nonwovens, both liquid andair. This is a process for producing fibrouswebs directly from polymers using highvelocity air to soothe the filaments.We offer a full range of pleated filters withmeltblown polyester and polypropylenemedia. These cartridges provide high solidloading capacity and long service life.Where cost efficiency is a must, chooseour meltblown filter cartridges.• Filtration levels are available in 1,3, 5,10,20,30, and 40 micron.• End cap configuration options are doubleopen end, single open end, single openend with aligning fin, and single open endwith either double -222 or -226 o-rings.We can also supply plastisol end capsin double open end.• The core is polypropylene.• Standard OD of all cartridges is 2-1/2 inch.• The temperature rating of the cartridges is225°F /105°.• Pressure rating is 150 psi with therecommended pressure drop for servicingrated at 35 psid max.HOW TO ORDERBuild an ordering code as shown in this example:PLEATED CARTRIDGE= PLMELTBLOWNMEDIAPolypropylenePolyesterMICRON SIZE*1, 3, 5, 10, 20, 30, 40= MB= PO= PEOVERALL LENGTH (IN)*9.75, 10, 19.5, 2029.5, 30, 39.5, 40PL - MB - PO - 3 - 10 - DOE-PO - B - OCOTHER OPTIONSAvailable with polypropylene end caps onlyF = Locator finOC = Polypropylene outer coreGASKET/O-RING OPTIONS*B = BunaV = VitonEND CAP CONFIGURATION*Polypropylene end cap optionsDOE-PO = Double open endSOE-PE = Single open end222-PO = 222 o-ringPlastisol end cap optionsDOE-PL = Double open end*Other micron sizes, lengths, end cap configurations and gasket/o-ring options may be available30

GASKET1-7/8 O.D.1-1/16HOLECARTRIDGELENGTHPLEATED2-5/831

A 2 -SERIES CARTRIDGE FILTER ELEMENTS<strong>Flow</strong> <strong>Ezy</strong> now offers true depthfiltration,continuous-woundcartridge elements in a wide rangeof materials, lengths, and micronretention ratings. A highlyinnovative single-core design isused, eliminating the “joints”common in other manufacturers’elements at 10-inch intervals.Available materials include cotton,acrylics, nylon, rayon, and polypropylene.Element lengths rangefrom 9-3/4 inches to 40 inches,fitting most cartridge filterhousings. Micron retention ratingsare from 200 down to 0.5 micron.These elements offer true depthfiltration, higher efficiency, lowerpressure drop and greater solidsholding capacity than standardelements, at a very competitive price.HOW TO ORDER A 2 -SERIES FILTER CARTRIDGESSelect the desired specifications from the ordering table and build an order code number, as shown in this example:CU - 15.0 - R - 30 - AMedia - Micron - Diameter - Length - Core MaterialFilter Microns Diameter Length CoreMedia (Nominal) (Nominal) (Nominal) MaterialCU 100.0 R 40 S(Natural Cotton) 75.0 (2.5") 39.5 (304 Stainless Steel)50.0 39C 30.0 30 A(White Cotton) 25.0 29.5 (316 Stainless Steel)20.0 20P 15.0 19.5 T(Polypropylene) 10.0 10 (Tin-Plated Steel)5.0 9.75PEP(Polyester)(Polypropylene)Note: Other media and micron sizesavailable by special order.If our standard cartridges do notmeet your specific requirements,consult the factory for availabilityof cartridges that will.32

Y-FILTERS ®BDDMODEL A B C DY-6 3-5/8 4-13/16 3-5/16 .9Y-15 5-1/16 6-3/8 4-5/8 1Y-25 6 7-1/2 5-1/4 1-3/16Y-45 7-1/4 8-1/8 6-1/2 1-9/16NPT ports are standard, but SAE straightthreadports may be ordered. Sizes are:Y-6 1-3/16-12Y-15 1-5/8-12Y-25 1-7/8-12ACEfficient, easilycleanedfilters,at the lowestpossible priceThese filters are built on the provendesign of the common "Y" strainer,but instead of a coarse screen,they contain a true micron-rated filterelement whose pleated elementsurface area is up to four timesgreater. In fact, the filtering area inthe "Y" filter design is equal to thatfound in standard hydraulic filters,but at a fraction of the cost!The flow path in the "Y" design isthrough the inside surface of theelement, where the contaminantis caught. There can be no dirt"wash-off" of the element downstreamduring servicing. This alsominimizes the formation of airpockets within the filter element.Many other stylesare available. Ask forour <strong>Catalog</strong> DCK.optionsSee How To Order for dirt indicator,magnets, and built-in bypass.HOW TO ORDERUse the flow rate table to select the proper model number andbuild an ordering code as shown in the example.EXAMPLE: Y - 15 - ST - 149 - F3 - 2 - M - SFILTER MODELPIPE SIZE SYMBOLINDICATORNo symbol = No indicatorNPT SAE (ST)S = Suction line indicator3/4 1-3/16-12 Y-6SM = Suction, with memory3/4 1-3/16-12 Y-6SS*R = Return line indicator3/4 1-3/16-12 Y-6AL**1-1/4 1-5/8-12 Y-151-1/2 1-7/8-12 Y-252 2-1/2-12 Y-45MAGNETSNo symbol = No magnetsELEMENT (Micron rating)595238149744025SEALBuna NViton= No symbol= F3MBYPASS VALVE2 = 2 psi3 = 3 psi5 = 5 psi15 = 15 psi= Magnets (except Y-6)Filter Element AreasModel Pipe ElementSize, Area,NPT Sq.-In.Y-6 3/4 17Y-15 1-1/4 56Y-25 1-1/2 84Y-45 2 125*Stainless Steel **Aluminum33

BY-FILTERS ®DELEMENT NUMBERSY6-595 6179-30Y6-238 6179Y6-149 6179-01Y6-74 6179-02Y6-40 6179-04Y6-25 6179-05Y15-595 - 6208-30Y15-238 6208Y15-149 6208-01Y15-74 6208-02Y15-40 6208-04Y15-25 6208-05Y25-595 6184-30Y25-238 6184Y25-149 6184-01Y25-74 6184-02Y25-40 6184-04Y25-25 6184-05Y45-595 - 8860-30Y45-238 8860Y45-149 8860-01Y45-74 8860-02Y45-40 8860-04Y45-25 8860-05Typical Suction andReturn line installations.Y2 Filter ElementY2 FILTERThe Y-2 is a tiny powerhouse. Rated at 250PSI and constructed of 316 stainless steel,this unit finds wide application in bothsuction and return line service.It's available in connection sizes of 1/4", 3/8"and 1/2" NPT. The stainless steel elementsare available in 595, 238, 149, 74, 63, 40and 25 micron.Screen:<strong>Flow</strong> Rate:Filtration Area:Weight:Dimensions:Stainless SteelUp to 2 GPM2.5 Square Inches8 Ounces2-1/2 x 2-1/4-in.HOW TO ORDERSelect the desired specifications from the ordering tableand build an ordering code number, as shown in this sample:MODELREPLACEMENTCODESCREENSY2 - SS - 1/4 - 149 - F3MODEL - MATERIAL - CONNECTION - MICRON - SEALS PART NO.MODEL HOUSING CONNECTION MICRON SEALS PARTNUMBER MATERIAL SIZE (NPT) SIZE (MICRON)Y2 SS 1/4-in. 595 No 6177-01 (595)(Stainless 3/8-in. 238 Symbol 6177-02 (238)Steel) 1/2-in. 149 Teflon 6177-03 (149)74 6177-06 (74)63 F3 6177-04 (63)40 Viton 6177-07 (40)25 6177-05 (25)34

T-FILTERS ®Sensible, high-capacity,highly-versatile filtersModel TF-U-L100shown in themost frequentT-Filter arrangement.On an L-shapedreservoir, aTF-D-S50 T-Filteris used to filterthe suction lineto the pump.An openbottomedModelTF-D-L45 filtersfluid as it returnsto the tank.Model TF-D-S23serves here as areturn-line filter.INININFLOWFLOW UPFLOWUPUP INININFLOWDOWN FLOWFLOW DOWNDOWN OUTOUTOUTFLOWDOWN FLOWFLOW DOWNDOWNOUTOUTOUTFLOWDOWN FLOWFLOWDOWNDOWNThe T-Filter concept is to providelarge-area (low pressure drop)filter elements, that are easilyreplaced, in low-cost housingsmade of welded steel tube.Elements can be cleanable wiremesh or throw-away fiber.Install inside or outside the tank.Eliminate the usual pipe betweentank and filter, and one pipe elbow.Two element lengths available.Long elements in housings withunthreaded bottoms are usuallyspecified for in-tank installations.The long elements also come inhousings with threaded bottomsfor piped installations.For lower capacity or morecompact installations, a seriesof short elements are available,in housings with threadedbottom ports only.Two element designs.One for "flow-up" and onefor "flow-down" filtering.Easy element servicing.Elements lift straight up outof the clean-out port, whichalso serves as a filling port.Filter Element Ratings and AreasRATING, umSQUARE INCHES OF ELEMENT PER MODELSYMBOL DESCRIPTION Nominal Absolute TF-L12 TF-L18 TF-L45 TF-L100 TF-S9 TF-S23 TF-S50TF-P12 TF-P18 TF-P45 TF-P100238 Stainless steel 238 - 120 230 315 460 115 157 230wire, 60 mesh149 Stainless Steel 149 - 120 230 315 460 115 157 230wire, 100 mesh74 Stainless steel 74 - 120 230 315 460 115 157 230wire, 200 mesh40A Synthetic fiber 50 85 N/A 150 360 680 75 180 340(single layer)15A Synthetic fiber 42 70 N/A 110 280 510 60 150 250(double layer)20C Cellulose fiber 23 65 N/A 223 580 1200 110 285 50010C Cellulose fiber 13 30 N/A 223 580 1200 110 285 50035

T-FILTERS ®Long (L)Ported (P)Short (S)Open-bottomedT-Filter is shown witha long flow-up typeelement.CDFBJELEMENTREMOVALCLEARANCECDFBJELEMENTREMOVALCLEARANCECDFBJELEMENTREMOVALCLEARANCET-Filter with a threadedport at the bottom isshown with a shortflow-down typeelement.EOPTIONALDIFFERENTALINDICATORPORTINSTALLERMAY CUTOFF TO SUITAEOPTIONALDIFFERENTALINDICATORPORT1" BYPASSVALVE ONFLOW-DOWNMODELSAEOPTIONALDIFFERENTALINDICATORPORT1" BYPASSVALVE ONFLOW-DOWNMODELSEHAHDIMENSIONSEHFILTER A B C D E F G H JMODEL LENGTH DIA. DIA. NPTL12 20-1/2 3-1/8 2-3/8 1-5/8 1 2-1/2 18-1/8 1-7/8 19L18 24-1/2 3-5/8 2-1/2 2 1-1/4 2-3/4 22 2-3/8 20L45 26-1/2 4-5/8 3 2-3/4 2 3-1/4 23-1/2 3-1/2 21L100 30-1/2 5-3/4 3-5/8 4 3 4-1/4 26-15/16 4-1/2 22P12 21 3-1/8 2-3/8 1-5/8 1 2-1/2 18-11/16 1-7/8 19P18 25 3-5/8 2-1/2 2 1-1/4 2-3/4 22-9/16 2-3/8 20P45 27-1/16 4-5/8 3 2-3/4 2 3-1/4 24-1/8 3-1/2 21P100 31-3/4 5-3/4 3-5/8 4 3 4-1/4 27-13/16 4-1/2 22S9 14-1/2 3-5/8 2-1/2 2 1-1/4 2-3/4 12-1/16 2-3/8 13S23 15-1/4 4-5/8 3 2-3/4 2 3-1/4 12-1/4 3-1/2 13S50 17-1/8 5-3/4 3-5/8 4 3 4-1/4 13-5/8 4-1/2 14-1/2HOW TO ORDEREXAMPLE: TF - U - L100 - 74 - F3 - 3 - M - SFILTER SERIEST-Filter = TFFLOW DIRECTIONUp= UDown = DFILTER MODELLong element, open(non-threaded) bottomL12, L18, L45, L100Long element, ported(threaded) bottomP12, P18, P45, P100Short element, ported(threaded) bottomS9, S23, S50ELEMENTCleanable wire mesh238, 149, 74Throwaway type15A, 40A, 20C, 10CINDICATORNo Symbol = No indicatorS = For Suction <strong>Line</strong>SM = Suction with memoryR = For Return <strong>Line</strong>DP = Pressure differentialindicatorMAGNETSNo Symbol = No magnetsM = MagnetsBYPASS VALVENo Symbol = No valve3 = 3 psi5 = 5 psi15 = 15 psi25 = 25 psiSEALSNo Symbol = Buna NF3 = Viton36

TEXAS FILTERS ®For effective low-cost,high volume filtrationSuction <strong>Line</strong> Filter SelectionSuction filters, the most importantfilter in the entire system, protectsthe the key system component, thepump. A single TEXAS Filter canclean hundreds of gallons of fluidper minute.Return <strong>Line</strong> Filter SelectionTEXAS <strong>Filters</strong> provide an idealway to pre-condition fluid to higherlevels of cleanliness before itreturns to the reservoir. (Returnline filter covers are made strongerfor the higher pressures found inthese applications.)ELEMENT DIMENSIONSTexas <strong>Filters</strong> are ordered for either"flow up or "flow down" use, to suityour system arrangement.MODEL O.D. I.D. LENGTH AREATXF-756847 (OBS)4-1/4 3-1/8 5-5/8 275TXF-10063484-1/2 3-1/8 7-1/2 375TXF-1506349 (OBS)5-7/8 4-7/8 8 500TXF-20063505-7/8 4-7/8 10-3/4 650TXF-3006351 (OBS)5-7/8 4-7/8 15-3/4 1000TXF-40063528-1/8 7-1/8 15 120037

TEXAS FILTERS ®HABGCDE1/4 NPT PORTFor Dirt IndicatorFCIDIMENSIONSMODEL USAGE PIPE A B C D E F G H ISIZETXF-100 SUCTION 3 5.31 4.81 4.00 4.38 15.50 2.69 2.69 7.31 5.88RETURN 1-1/2 4.71 3.81 2.20 5.38 14.25 1.44 1.69TXF-200 SUCTION 4 6.62 5.31 5.00 5.5 20.12 2.88 3.19 9.88 8.12RETURN 2-1/2 6.79 4.44 3.25 6.38 19.75 2.50 2.31TXF-400 SUCTION 6 7.36 6.44 7.39 6.5 26.00 3.38 4.31 11.88 10.25RETURN 4 7.83 5.31 5.00 7.62 25.50 2.88 3.19HOW TO ORDEREXAMPLE: T XF-200 - S - U - F - 74 - F3 - RV3 - M - SMFILTER MODELTXF-100TXF-200TXF-400USAGESUCTION = SRETURN = RFLOW DIRECTIONUp = UDown = DPORT STYLEFEMALE NPT COUPLING = FELEMENT MICRON RATING5952381497440W2540ADIRT INDICATORNo Symbol = No indicatorS = For Suction <strong>Line</strong>SM = Suction with memoryR = For Return <strong>Line</strong>MAGNETSNo Symbol = No magnetsM = MagnetsBYPASS VALVERV3 = 3 psiRV5 = 5 psiRV15 = 15 psiSEALSNo Symbol = Buna NF3 = Viton38

TEE-EZY TM FILTERSGPIPE SIZE JGPIPE SIZE Jpipe up low-costfilters with tee-ezy,and save up to 60%AB C EFPIPE SIZE HA B C EFPIPE SIZE HThat's right! With your piping ourTee-<strong>Ezy</strong> kit, you'll have a true filteringsystem (down to 3 micron) for slightlymore than you're now paying for acommon sump strainer and the sameamount of pipe, fittings and labor, plus:SUCTION LINE Typical installationshows how pipe acts as a housingaround filter element. Standpipedoes not entirely enclose the TU-serieselement: it need only extend to belowminimum fluid level of the tank.A vacuum gage may be mountedjust ahead of pump to indicatedifferential pressure across the filter.AB C EDGPIPE SIZE JFPIPE SIZE HA B C EDGPIPE SIZE JFPIPE SIZE H• You can clean and replace thefiltering element without draining thetank or taking apart piping.• You can monitor filter dirt build-up byadding a dirt indicator.• Optional bypass valves are builtin to product the system from adirt-clogged filter.• You can filter suction or return lines.GPIPE SIZE JDDFRETURN LINE Typical installationshows that piping set-up is similarto suction line installation: The onlydifference is that the TD-serieselement is used, to handle flow"down" rather than "up".AB C EPIPE SIZE HADIMENSIONSFILTER ELEMENT A B C D E F G H JSIZE PORE OVERALL ELEMNT LENGTH* END CAP MEDIA O-RING SPECS:SIZE LENGTH* O.D. LENGTH DASH NO. / X-SECTIONTS-12 ALLL 19-1/4 18-3/4 16 1.385 14 220/.139 137/.103 1-1/2 1TS-18 60,100,200 19-7/8 19-3/8 16-3/8 1.835 14 225/.139 144/.103 2 1-1/4ALL OTHERS 19-7/8 19-3/8 16-3/4 1.835TS-45 60,100,200 21-1/4 20-3/4 16-3/4 2.234 14 233/.139 153/.103 3 2ALL OTHERS 21-1/4 20-3/4 16-3/4 2.864TS-100 60,100,200 23-3/4 23-1/4 18-3/8 2.862 14 241/.139 247/.139 4 3ALL OTHERS 21-1/4 20-3/4 16-3/4 2.864D39

TEE-EZY TM FILTERSINSTALLATIONWhen laying out assembly:1. Be sure there's clearance toremove the element assemblyfrom the piped housing.For size 12, 18 and 45, you'llneed 22 inches, and for size100, 25 inches.2. In suction-line applications,pipe flow comes in at the end,or from all sides (Fig. 1 and 2).Don't let flow impinge againstone side only (Fig. 3).The more exposed anelement, the longer it willserve without clogging.3. Use standard schedule40 pipe and 125-psipressure service fittings.The important O-ring seal:To prevent fluid frombypassing the element, anO-ring is used to seal thespace between the cartridgeand the pipe housing. Becausethe I.D. of schedule 40 pipe mayvary beyond the sealing rangeof the O-ring, a properly sizedand machined nipple can beordered. It is threaded intothe bottom of the tee.If you don't wish to use thenipple, use any schedule40 pipe that you can sealwith the O-ring (see O-ringspecs), and give it the properinternal chamfer, to compressthe O-ring. See Fig. 4.(Always lubricate O-ringbefore inserting cartridge.)4. If you use the premachinednipple, youmust file an entry bevelof about 15° by 1/8 in.on the I.D. of the standpipe.The I.D. of the pipe mustbe such that the O-ringseals against it.5. To install the clean-outport in your tee fitting, asimple wrench adapter likethat shown is easily made up.1.2.3.4.5.PERFORMANCETEE-EZY Filter Element GPM @Size Designation Pore Size 1 P.S.I.D.*TS-12 60, 100 or 200 Mesh (74 µm) 12TS-18 60, 100 or 200 Mesh (74 µm) 1815 or 40 Micron 14.820 Micron 9.710 Micron 1.9TS-45 60, 100 or 200 Mesh (74 µm) 4540 Micron 3920 Micron 2515 Micron 3810 Micron 53 Micron 4TS-100 60, 100 or 200 Mesh (74 µm) 10040 Micron 7420 Micron 6215 Micron 7110 Micron 123 Micron 8* Pounds per square inch differential pressure, using 150 SSU viscosity oil.All figures were developed using clean elements and standpipes that extendedbeyond end of element cartridges.Recommended piping, that exposes end of cartridge (as shown in drawings),would provide higher flows at same pressure differentials.HOW TO ORDERFirst, build an ordering code for the clean-outport and cover, as in this example:TS - 18 - N - F3Style - Size - Nipple - Viton O-RingSTYLE SIZE NIPPLE O-RINGTS 12 N No Symbol = Buna N18 (nipple with45 machined I.D. F3 = Viton100 for good O-Ring seal)Second, build an ordering code for the replacementelement assembly, as in this example:TU - 18 - 74 - RV3 - F3Style - Size - Element - Valve - Viton O-RingSTYLE SIZE ELEMENT GRADE BYPASS O-RING(Micron Size)TU 238 micron RV3 No Symbol(<strong>Flow</strong> up 12 149 micron (3-psi) = Buna-Nfor suction74 micronline)RV518 149 micron(5-psi)74 micronTD 45 40 micron, synthetic(<strong>Flow</strong> downRV15 F3for return 20 micron, cellulose (15-psi) = Vitonline) 100 15 micron, double syn.10 micron, cellulose RV3045 3G 3 micron, (30-psi)100 micro glass40

Models 4, 6, 8 High-Capacity Strainers and <strong>Filters</strong>Strainers or Bag <strong>Filters</strong> for Hydraulic Fluids and Other OilsStrainer/filter housings are madein many sizes, and all can serve asbasket strainers (for particle retentiondown to 74 micron size) or as bagfilters (for particle retention down to1 micron size). In all cases, covesare easily removed, without tools,and the basket or bag is easilycleaned or replaced.FEATURES• Large-area, heavy-duty baskets• Low pressure drops• Housings are permanently piped• Covers are O-ring sealed• Carbon steel, or stainless steel(304 or 316) housings• All housings are electropolishedto resist adhesion of dirt and scale• Adjustable-height legs, standardon Models 6 and 8; optional extraon Model 4• Easy to clean• Liquid displacers for easierservicing (optional)These filters meet the more exactingneeds of hydraulic and lubricatingfluid filtration.Construction MaterialsAll housings and other wettedparts not otherwise specified canbe ordered in carbon steel, 304stainless steel, or 316 stainlesssteel. Four different materials canbe ordered for all seals involved.All baskets and mesh linings aremade of stainless steel. 304stainless steel will be supplied withcarbon and 304 housings, 316stainless with 316 housings.Choose a basket straineror bag filterOnce the choice between straininga fluid (removing particles down toone 74 micron size) and filtering it(removing particles down to onemicron) has been made, the choiceof which size <strong>Flow</strong> <strong>Ezy</strong> filter modelmust be made. All three models(4, 6 and 8) and the baskets andbags that go in them, are of thesame basic design. They differin dimensions, capacities,maximum pressure ratings,and pipe size. Selection isbased on these variables.Pressure DropBasket strainers and bag filtersare usually selected so that thepressure drop does not exceed 2psi, when they are clean. Higherpressure drops may be toleratedwhen contaminant loading is low.That pressure drop informationis accurate for all housings withstrainer or filter bag baskets only.When filter bags are added, thetotal pressure drop becomes thesum of the existing pressure dropplus the pressure drop through thebag. Consult the factory for theformula to determine the pressuredrop for your application.Model 6Model 4Model 8Additional sizes areavailable. Ask for ourBag Filter <strong>Catalog</strong>.41