Eaton Axle and Brake Service Manual. 2-Speed and Double ...

Eaton Axle and Brake Service Manual. 2-Speed and Double ...

Eaton Axle and Brake Service Manual. 2-Speed and Double ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

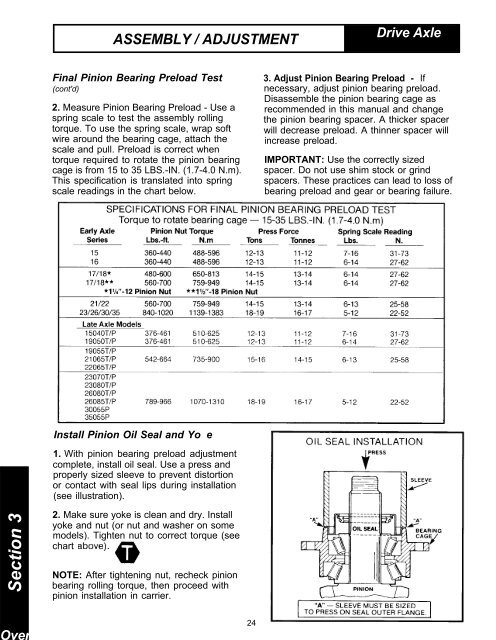

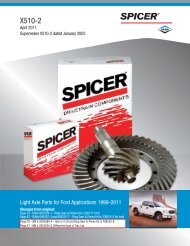

ASSEMBLY / ADJUSTMENTDrive <strong>Axle</strong>Final Pinion Bearing Preload Test(cont'd)2. Measure Pinion Bearing Preload - Use aspring scale to test the assembly rollingtorque. To use the spring scale, wrap softwire around the bearing cage, attach thescale <strong>and</strong> pull. Preload is correct whentorque required to rotate the pinion bearingcage is from 15 to 35 LBS.-IN. (1.7-4.0 N.m).This specification is translated into springscale readings in the chart below.3. Adjust Pinion Bearing Preload - Ifnecessary, adjust pinion bearing preload.Disassemble the pinion bearing cage asrecommended in this manual <strong>and</strong> changethe pinion bearing spacer. A thicker spacerwill decrease preload. A thinner spacer willincrease preload.IMPORTANT: Use the correctly sizedspacer. Do not use shim stock or grindspacers. These practices can lead to loss ofbearing preload <strong>and</strong> gear or bearing failure.Install Pinion Oil Seal <strong>and</strong> Yoke1. With pinion bearing preload adjustmentcomplete, install oil seal. Use a press <strong>and</strong>properly sized sleeve to prevent distortionor contact with seal lips during installation(see illustration).Section 32. Make sure yoke is clean <strong>and</strong> dry. Installyoke <strong>and</strong> nut (or nut <strong>and</strong> washer on somemodels). Tighten nut to correct torque (see .chart above~.NOTE: After tightening nut, recheck pinionbearing rolling torque, then proceed withpinion installation in carrier.Overhaul24