Eaton Axle and Brake Service Manual. 2-Speed and Double ...

Eaton Axle and Brake Service Manual. 2-Speed and Double ...

Eaton Axle and Brake Service Manual. 2-Speed and Double ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

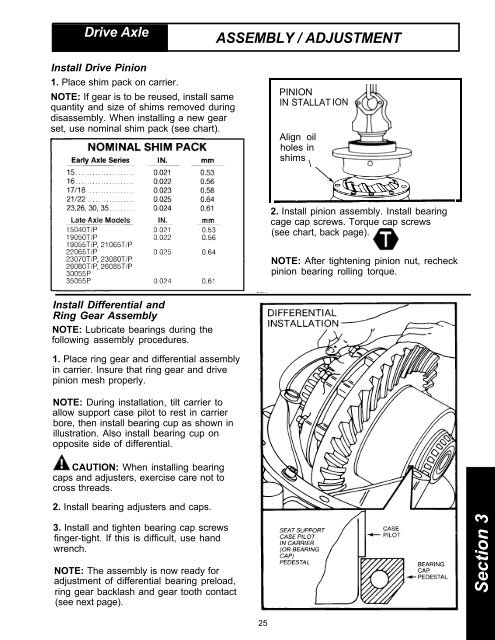

Drive <strong>Axle</strong>ASSEMBLY / ADJUSTMENTInstall Drive Pinion1. Place shim pack on carrier.NOTE: If gear is to be reused, install samequantity <strong>and</strong> size of shims removed duringdisassembly. When installing a new gearset, use nominal shim pack (see chart).PINIONIN STALLAT IONAlign oilholes inshims \2. Install pinion assembly. Install bearingcage cap screws. Torque cap screws(see chart, back page).NOTE: After tightening pinion nut, recheckpinion bearing rolling torque.Install Differential <strong>and</strong>Ring Gear AssemblyNOTE: Lubricate bearings during thefollowing assembly procedures.1. Place ring gear <strong>and</strong> differential assemblyin carrier. Insure that ring gear <strong>and</strong> drivepinion mesh properly.NOTE: During installation, tilt carrier toallow support case pilot to rest in carrierbore, then install bearing cup as shown inillustration. Also install bearing cup onopposite side of differential.CAUTION: When installing bearingcaps <strong>and</strong> adjusters, exercise care not tocross threads.2. Install bearing adjusters <strong>and</strong> caps.3. Install <strong>and</strong> tighten bearing cap screwsfinger-tight. If this is difficult, use h<strong>and</strong>wrench.NOTE: The assembly is now ready foradjustment of differential bearing preload,ring gear backlash <strong>and</strong> gear tooth contact(see next page).Section 3Overhaul25