Product Guide 2012 - Lantech Communications Global Inc

Product Guide 2012 - Lantech Communications Global Inc

Product Guide 2012 - Lantech Communications Global Inc

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

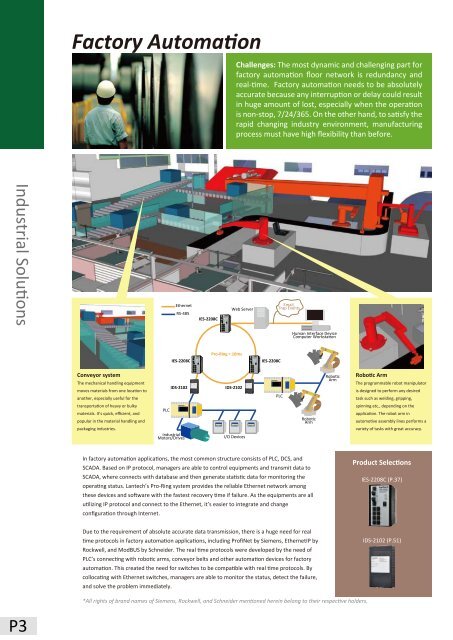

Factory AutomationChallenges: The most dynamic and challenging part forfactory automation floor network is redundancy andreal-time. Factory automation needs to be absolutelyaccurate because any interruption or delay could resultin huge amount of lost, especially when the operationis non-stop, 7/24/365. On the other hand, to satisfy therapid changing industry environment, manufacturingprocess must have high flexibility than before.Industrial SolutionsEthernetRS-485IES-2208CWeb ServerEmail,Trap EventsHuman Interface DeviceComputer WorkstationPro-Ring < 10msIES-2208CIES-2208CConveyor systemThe mechanical handling equipmentmoves materials from one location toanother, especially useful for theIDS-2102IDS-2102<strong>Lantech</strong>PLCRoboticArmRobotic ArmThe programmable robot manipulatoris designed to perform any desiredtask such as welding, gripping,transportation of heavy or bulkymaterials. It’s quick, efficient, andpopular in the material handling andpackaging industries.PLC<strong>Lantech</strong>IndustrialMotors/DrivesI/O DevicesRoboticArmspinning etc., depending on theapplication. The robot arm inautomotive assembly lines performs avariety of tasks with great accuracy.In factory automation applications, the most common structure consists of PLC, DCS, andSCADA. Based on IP protocol, managers are able to control equipments and transmit data toSCADA, where connects with database and then generate statistic data for monitoring theoperating status. <strong>Lantech</strong>’s Pro-Ring system provides the reliable Ethernet network amongthese devices and software with the fastest recovery time if failure. As the equipments are allutilizing IP protocol and connect to the Ethernet, it’s easier to integrate and changeconfiguration through Internet.<strong>Product</strong> SelectionsIES-2208C (P.37)Due to the requirement of absolute accurate data transmission, there is a huge need for realtime protocols in factory automation applications, including ProfiNet by Siemens, EthernetIP byRockwell, and ModBUS by Schneider. The real time protocols were developed by the need ofPLC’s connecting with robotic arms, conveyor belts and other automation devices for factoryautomation. This created the need for switches to be compatible with real time protocols. Bycollocating with Ethernet switches, managers are able to monitor the status, detect the failure,and solve the problem immediately.IDS-2102 (P.51)*All rights of brand names of Siemens, Rockwell, and Schneider mentioned herein belong to their respective holders.P3