Phase 4 â Wire L.T. Solid State ( Static) Whole Current ... - WBSEDCL

Phase 4 â Wire L.T. Solid State ( Static) Whole Current ... - WBSEDCL

Phase 4 â Wire L.T. Solid State ( Static) Whole Current ... - WBSEDCL

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

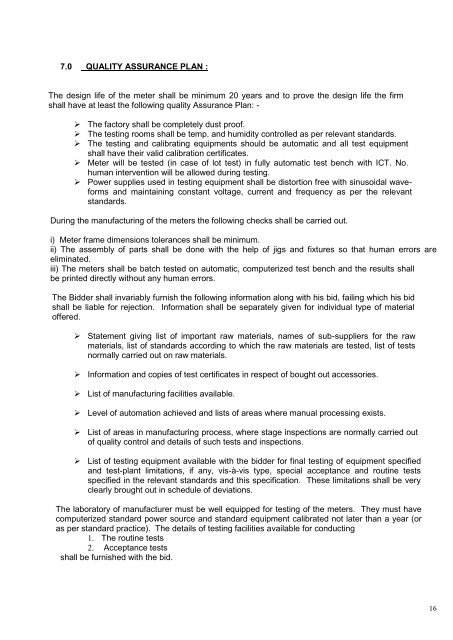

7.0 QUALITY ASSURANCE PLAN :The design life of the meter shall be minimum 20 years and to prove the design life the firmshall have at least the following quality Assurance Plan: -‣ The factory shall be completely dust proof.‣ The testing rooms shall be temp. and humidity controlled as per relevant standards.‣ The testing and calibrating equipments should be automatic and all test equipmentshall have their valid calibration certificates.‣ Meter will be tested (in case of lot test) in fully automatic test bench with ICT. No.human intervention will be allowed during testing.‣ Power supplies used in testing equipment shall be distortion free with sinusoidal waveformsand maintaining constant voltage, current and frequency as per the relevantstandards.During the manufacturing of the meters the following checks shall be carried out.i) Meter frame dimensions tolerances shall be minimum.ii) The assembly of parts shall be done with the help of jigs and fixtures so that human errors areeliminated.iii) The meters shall be batch tested on automatic, computerized test bench and the results shallbe printed directly without any human errors.The Bidder shall invariably furnish the following information along with his bid, failing which his bidshall be liable for rejection. Information shall be separately given for individual type of materialoffered.‣ <strong>State</strong>ment giving list of important raw materials, names of sub-suppliers for the rawmaterials, list of standards according to which the raw materials are tested, list of testsnormally carried out on raw materials.‣ Information and copies of test certificates in respect of bought out accessories.‣ List of manufacturing facilities available.‣ Level of automation achieved and lists of areas where manual processing exists.‣ List of areas in manufacturing process, where stage inspections are normally carried outof quality control and details of such tests and inspections.‣ List of testing equipment available with the bidder for final testing of equipment specifiedand test-plant limitations, if any, vis-à-vis type, special acceptance and routine testsspecified in the relevant standards and this specification. These limitations shall be veryclearly brought out in schedule of deviations.The laboratory of manufacturer must be well equipped for testing of the meters. They must havecomputerized standard power source and standard equipment calibrated not later than a year (oras per standard practice). The details of testing facilities available for conducting1. The routine tests2. Acceptance testsshall be furnished with the bid.16