6. LPC Bituminous Mixtures Design Guide, Sept 2007. - Aapaq.org

6. LPC Bituminous Mixtures Design Guide, Sept 2007. - Aapaq.org

6. LPC Bituminous Mixtures Design Guide, Sept 2007. - Aapaq.org

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

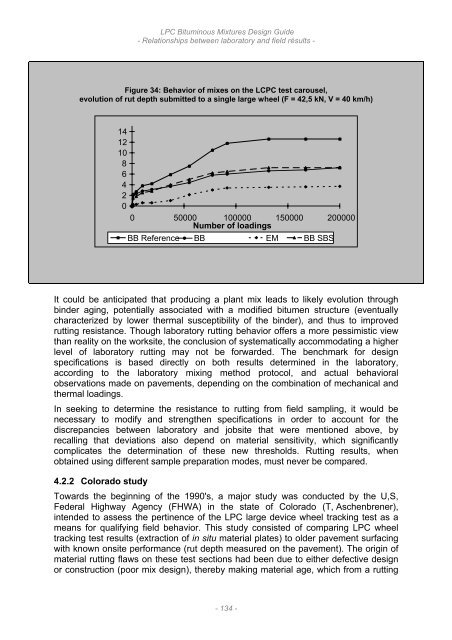

<strong>LPC</strong> <strong>Bituminous</strong> <strong>Mixtures</strong> <strong>Design</strong> <strong>Guide</strong>- Relationships between laboratory and field résults -Figure 34: Behavior of mixes on the LCPC test carousel,evolution of rut depth submitted to a single large wheel (F = 42,5 kN, V = 40 km/h)141210864200 50000 100000 150000 200000Number of loadingsBB Reference BB EM BB SBSIt could be anticipated that producing a plant mix leads to likely evolution throughbinder aging, potentially associated with a modified bitumen structure (eventuallycharacterized by lower thermal susceptibility of the binder), and thus to improvedrutting resistance. Though laboratory rutting behavior offers a more pessimistic viewthan reality on the worksite, the conclusion of systematically accommodating a higherlevel of laboratory rutting may not be forwarded. The benchmark for designspecifications is based directly on both results determined in the laboratory,according to the laboratory mixing method protocol, and actual behavioralobservations made on pavements, depending on the combination of mechanical andthermal loadings.In seeking to determine the resistance to rutting from field sampling, it would benecessary to modify and strengthen specifications in order to account for thediscrepancies between laboratory and jobsite that were mentioned above, byrecalling that deviations also depend on material sensitivity, which significantlycomplicates the determination of these new thresholds. Rutting results, whenobtained using different sample preparation modes, must never be compared.4.2.2 Colorado studyTowards the beginning of the 1990's, a major study was conducted by the U,S,Federal Highway Agency (FHWA) in the state of Colorado (T, Aschenbrener),intended to assess the pertinence of the <strong>LPC</strong> large device wheel tracking test as ameans for qualifying field behavior. This study consisted of comparing <strong>LPC</strong> wheeltracking test results (extraction of in situ material plates) to older pavement surfacingwith known onsite performance (rut depth measured on the pavement). The origin ofmaterial rutting flaws on these test sections had been due to either defective designor construction (poor mix design), thereby making material age, which from a rutting- 134 -