6. LPC Bituminous Mixtures Design Guide, Sept 2007. - Aapaq.org

6. LPC Bituminous Mixtures Design Guide, Sept 2007. - Aapaq.org

6. LPC Bituminous Mixtures Design Guide, Sept 2007. - Aapaq.org

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

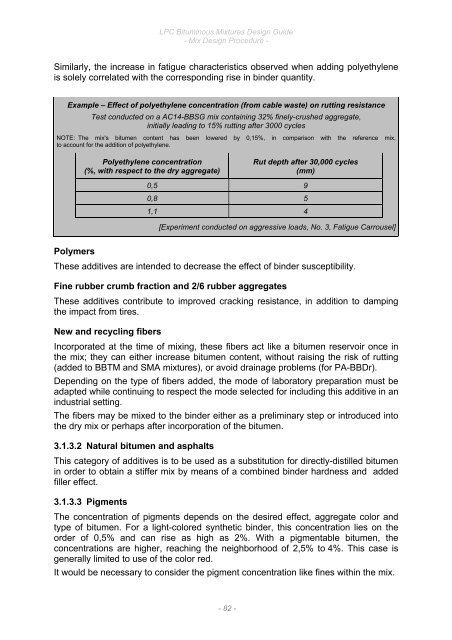

<strong>LPC</strong> <strong>Bituminous</strong> <strong>Mixtures</strong> <strong>Design</strong> <strong>Guide</strong>- Mix <strong>Design</strong> Procedure -Similarly, the increase in fatigue characteristics observed when adding polyethyleneis solely correlated with the corresponding rise in binder quantity.Example – Effect of polyethylene concentration (from cable waste) on rutting resistanceTest conducted on a AC14-BBSG mix containing 32% finely-crushed aggregate,initially leading to 15% rutting after 3000 cyclesNOTE: The mix's bitumen content has been lowered by 0,15%, in comparison with the reference mix,to account for the addition of polyethylene.Polyethylene concentration(%, with respect to the dry aggregate)Rut depth after 30,000 cycles(mm)0,5 90,8 51,1 4[Experiment conducted on aggressive loads, No. 3, Fatigue Carrousel]PolymersThese additives are intended to decrease the effect of binder susceptibility.Fine rubber crumb fraction and 2/6 rubber aggregatesThese additives contribute to improved cracking resistance, in addition to dampingthe impact from tires.New and recycling fibersIncorporated at the time of mixing, these fibers act like a bitumen reservoir once inthe mix; they can either increase bitumen content, without raising the risk of rutting(added to BBTM and SMA mixtures), or avoid drainage problems (for PA-BBDr).Depending on the type of fibers added, the mode of laboratory preparation must beadapted while continuing to respect the mode selected for including this additive in anindustrial setting.The fibers may be mixed to the binder either as a preliminary step or introduced intothe dry mix or perhaps after incorporation of the bitumen.3.1.3.2 Natural bitumen and asphaltsThis category of additives is to be used as a substitution for directly-distilled bitumenin order to obtain a stiffer mix by means of a combined binder hardness and addedfiller effect.3.1.3.3 PigmentsThe concentration of pigments depends on the desired effect, aggregate color andtype of bitumen. For a light-colored synthetic binder, this concentration lies on theorder of 0,5% and can rise as high as 2%. With a pigmentable bitumen, theconcentrations are higher, reaching the neighborhood of 2,5% to 4%. This case isgenerally limited to use of the color red.It would be necessary to consider the pigment concentration like fines within the mix.- 82 -