6. LPC Bituminous Mixtures Design Guide, Sept 2007. - Aapaq.org

6. LPC Bituminous Mixtures Design Guide, Sept 2007. - Aapaq.org

6. LPC Bituminous Mixtures Design Guide, Sept 2007. - Aapaq.org

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

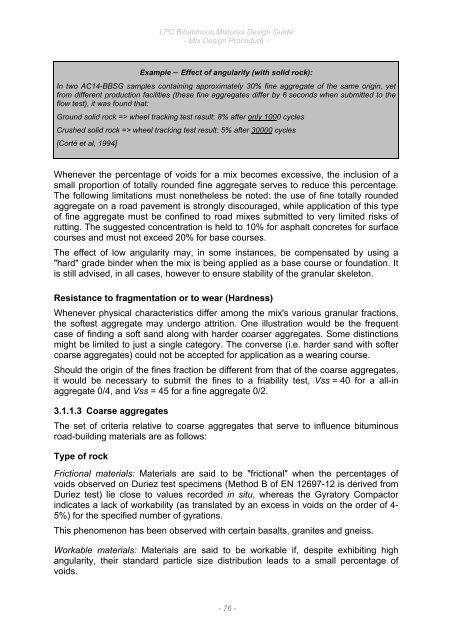

<strong>LPC</strong> <strong>Bituminous</strong> <strong>Mixtures</strong> <strong>Design</strong> <strong>Guide</strong>- Mix <strong>Design</strong> Procedure -Example – Effect of angularity (with solid rock):In two AC14-BBSG samples containing approximately 30% fine aggregate of the same origin, yetfrom different production facilities (these fine aggregates differ by 6 seconds when submitted to theflow test), it was found that:Ground solid rock => wheel tracking test result: 8% after only 1000 cyclesCrushed solid rock => wheel tracking test result: 5% after 30000 cycles[Corté et al, 1994]Whenever the percentage of voids for a mix becomes excessive, the inclusion of asmall proportion of totally rounded fine aggregate serves to reduce this percentage.The following limitations must nonetheless be noted: the use of fine totally roundedaggregate on a road pavement is strongly discouraged, while application of this typeof fine aggregate must be confined to road mixes submitted to very limited risks ofrutting. The suggested concentration is held to 10% for asphalt concretes for surfacecourses and must not exceed 20% for base courses.The effect of low angularity may, in some instances, be compensated by using a"hard" grade binder when the mix is being applied as a base course or foundation. Itis still advised, in all cases, however to ensure stability of the granular skeleton.Resistance to fragmentation or to wear (Hardness)Whenever physical characteristics differ among the mix's various granular fractions,the softest aggregate may undergo attrition. One illustration would be the frequentcase of finding a soft sand along with harder coarser aggregates. Some distinctionsmight be limited to just a single category. The converse (i.e. harder sand with softercoarse aggregates) could not be accepted for application as a wearing course.Should the origin of the fines fraction be different from that of the coarse aggregates,it would be necessary to submit the fines to a friability test, Vss = 40 for a all-inaggregate 0/4, and Vss = 45 for a fine aggregate 0/2.3.1.1.3 Coarse aggregatesThe set of criteria relative to coarse aggregates that serve to influence bituminousroad-building materials are as follows:Type of rockFrictional materials: Materials are said to be "frictional" when the percentages ofvoids observed on Duriez test specimens (Method B of EN 12697-12 is derived fromDuriez test) lie close to values recorded in situ, whereas the Gyratory Compactorindicates a lack of workability (as translated by an excess in voids on the order of 4-5%) for the specified number of gyrations.This phenomenon has been observed with certain basalts, granites and gneiss.Workable materials: Materials are said to be workable if, despite exhibiting highangularity, their standard particle size distribution leads to a small percentage ofvoids.- 76 -