6. LPC Bituminous Mixtures Design Guide, Sept 2007. - Aapaq.org

6. LPC Bituminous Mixtures Design Guide, Sept 2007. - Aapaq.org

6. LPC Bituminous Mixtures Design Guide, Sept 2007. - Aapaq.org

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

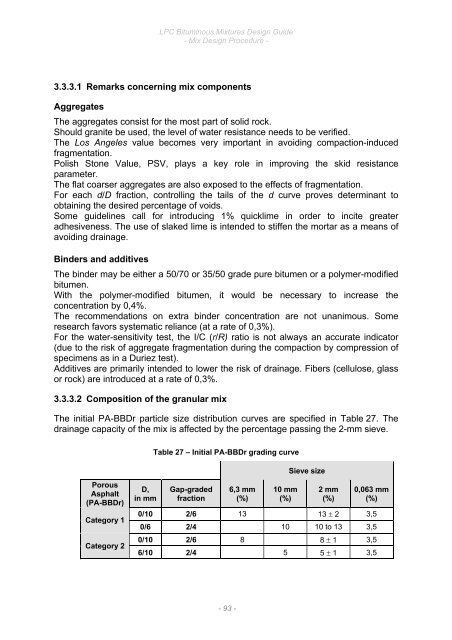

<strong>LPC</strong> <strong>Bituminous</strong> <strong>Mixtures</strong> <strong>Design</strong> <strong>Guide</strong>- Mix <strong>Design</strong> Procedure -3.3.3.1 Remarks concerning mix componentsAggregatesThe aggregates consist for the most part of solid rock.Should granite be used, the level of water resistance needs to be verified.The Los Angeles value becomes very important in avoiding compaction-inducedfragmentation.Polish Stone Value, PSV, plays a key role in improving the skid resistanceparameter.The flat coarser aggregates are also exposed to the effects of fragmentation.For each d/D fraction, controlling the tails of the d curve proves determinant toobtaining the desired percentage of voids.Some guidelines call for introducing 1% quicklime in order to incite greateradhesiveness. The use of slaked lime is intended to stiffen the mortar as a means ofavoiding drainage.Binders and additivesThe binder may be either a 50/70 or 35/50 grade pure bitumen or a polymer-modifiedbitumen.With the polymer-modified bitumen, it would be necessary to increase theconcentration by 0,4%.The recommendations on extra binder concentration are not unanimous. Someresearch favors systematic reliance (at a rate of 0,3%).For the water-sensitivity test, the I/C (r/R) ratio is not always an accurate indicator(due to the risk of aggregate fragmentation during the compaction by compression ofspecimens as in a Duriez test).Additives are primarily intended to lower the risk of drainage. Fibers (cellulose, glassor rock) are introduced at a rate of 0,3%.3.3.3.2 Composition of the granular mixThe initial PA-BBDr particle size distribution curves are specified in Table 27. Thedrainage capacity of the mix is affected by the percentage passing the 2-mm sieve.Table 27 – Initial PA-BBDr grading curveSieve sizePorousAsphalt(PA-BBDr)Category 1Category 2D,in mmGap-gradedfraction6,3 mm(%)10 mm(%)2 mm(%)0,063 mm(%)0/10 2/6 13 13 ± 2 3,50/6 2/4 10 10 to 13 3,50/10 2/6 8 8 ± 1 3,56/10 2/4 5 5 ± 1 3,5- 93 -