You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

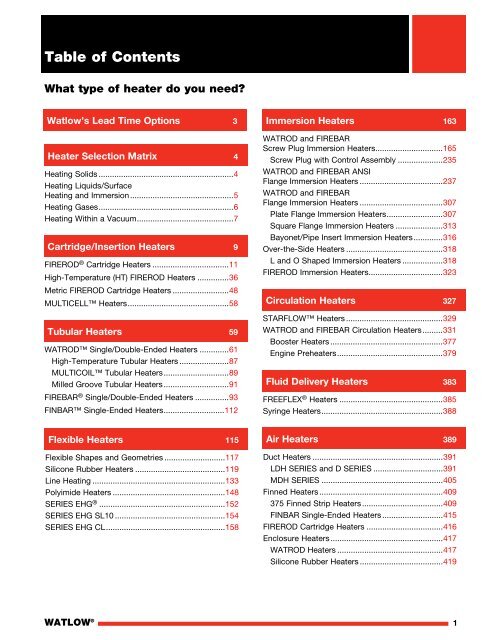

Table of ContentsWhat type of heater do you need?<strong>Watlow</strong>’s Lead Time Options 3<strong>Heater</strong> Selection Matrix 4Heating Solids.............................................................4Heating Liquids/SurfaceHeating and Immersion...............................................5Heating Gases.............................................................6Heating Within a Vacuum............................................7Cartridge/Insertion <strong>Heater</strong>s 9FIREROD ® Cartridge <strong>Heater</strong>s...................................11High-Temperature (HT) FIREROD <strong>Heater</strong>s...............36Metric FIREROD Cartridge <strong>Heater</strong>s..........................48MULTICELL <strong>Heater</strong>s..............................................58Tubular <strong>Heater</strong>s 59WATROD Single/Double-Ended <strong>Heater</strong>s..............61High-Temperature Tubular <strong>Heater</strong>s.......................87MULTICOIL Tubular <strong>Heater</strong>s..............................89Milled Groove Tubular <strong>Heater</strong>s..............................91FIREBAR ® Single/Double-Ended <strong>Heater</strong>s................93FINBAR Single-Ended <strong>Heater</strong>s............................112Immersion <strong>Heater</strong>s 163WATROD and FIREBARScrew Plug Immersion <strong>Heater</strong>s...............................165Screw Plug with Control Assembly.....................235WATROD and FIREBAR ANSIFlange Immersion <strong>Heater</strong>s......................................237WATROD and FIREBARFlange Immersion <strong>Heater</strong>s......................................307Plate Flange Immersion <strong>Heater</strong>s..........................307Square Flange Immersion <strong>Heater</strong>s......................313Bayonet/Pipe Insert Immersion <strong>Heater</strong>s..............316Over-the-Side <strong>Heater</strong>s............................................318L and O Shaped Immersion <strong>Heater</strong>s...................318FIREROD Immersion <strong>Heater</strong>s..................................323Circulation <strong>Heater</strong>s 327STARFLOW <strong>Heater</strong>s............................................329WATROD and FIREBAR Circulation <strong>Heater</strong>s..........331Booster <strong>Heater</strong>s...................................................377Engine Preheaters................................................379Fluid Delivery <strong>Heater</strong>s 383FREEFLEX ® <strong>Heater</strong>s...............................................385Syringe <strong>Heater</strong>s.......................................................388Flexible <strong>Heater</strong>s 115Flexible Shapes and Geometries............................117Silicone Rubber <strong>Heater</strong>s.........................................119Line Heating............................................................133Polyimide <strong>Heater</strong>s...................................................148SERIES EHG ® .........................................................152SERIES EHG SL10..................................................154SERIES EHG CL......................................................158Air <strong>Heater</strong>s 389Duct <strong>Heater</strong>s...........................................................391LDH SERIES and D SERIES................................391MDH SERIES.......................................................405Finned <strong>Heater</strong>s........................................................409375 Finned Strip <strong>Heater</strong>s.....................................409FINBAR Single-Ended <strong>Heater</strong>s............................415FIREROD Cartridge <strong>Heater</strong>s...................................416Enclosure <strong>Heater</strong>s...................................................417WATROD <strong>Heater</strong>s................................................417Silicone Rubber <strong>Heater</strong>s......................................419WATLOW ®1

Table of ContentsHigh-Temperature <strong>Heater</strong>s 423MULTICELL <strong>Heater</strong>s...............................................425High-Temperature FIREROD <strong>Heater</strong>s.....................431High-Temperature Tubular <strong>Heater</strong>s........................432Ceramic Fiber <strong>Heater</strong>s............................................433Specialty <strong>Heater</strong>s 457ULTRAMIC ® Advanced Ceramic <strong>Heater</strong>s...............459Thick Film Conduction <strong>Heater</strong>s...............................463Coil/Cable <strong>Heater</strong>s..................................................467Reference Data 541Power Calculations.................................................543Equations................................................................549Wattage Requirements............................................551Tubular Elements and AssemblySelection Guide.......................................................553Agency Certifications,Recognition and Approvals 561WATROD and FIREBAR Elementand Assemblies.......................................................563Strip/Clamp-On <strong>Heater</strong>s 475Mineral Insulated (MI) Strip <strong>Heater</strong>s........................477375 High-Temperature Strip <strong>Heater</strong>s......................481FIREBAR Clamp-On <strong>Heater</strong>s..................................489Thick Film Conduction <strong>Heater</strong>s...............................490Band/Barrel <strong>Heater</strong>s 491Index 569Product Category Index..........................................571Part Number Index..................................................572Terms and Conditions of Sale 575Terms and Conditions of Sale................................575Mineral Insulated (MI) Band <strong>Heater</strong>s.......................493Nozzle <strong>Heater</strong>s 505Mineral Insulated (MI) Nozzle <strong>Heater</strong>s....................507Pre-Coiled Cable Nozzle <strong>Heater</strong>s...........................509Radiant <strong>Heater</strong>s 511RAYMAX ® Panel <strong>Heater</strong>s........................................513MI Band and Strip Emitters.....................................527Thermostats and Accessories 529ST10 and ST207.....................................................531Bulb and Capillary...................................................534Protective Wells......................................................5392WATLOW ®

<strong>Watlow</strong>’s Lead Time OptionsTo remain competitive in our fast-paced world, you need a supplier that is committed to helping you succeed.<strong>Watlow</strong> ® shows its commitment through multiple options designed to get you what you need quickly.<strong>Watlow</strong> understands that your heating requirements vary from application to application. To help meet your individualneeds, <strong>Watlow</strong> offers several options to ensure you receive your product when you need it.RAPID SHIP and Manufacturing Lead TimesRAPID SHIP<strong>Watlow</strong>’s industry-leading RAPID SHIP offering is available throughout the catalog for various products. RAPID SHIPproducts are noted with “RS” and the RAPID SHIP logo. RAPID SHIP assures that your products will be manufacturedand shipped from the factory the next business day.Products not available as RAPID SHIP will be noted with an “M” which stands for Manufacturing lead times. In manyinstances Manufacturing lead times are just a few days longer than RAPID SHIP due to lower volumes, unique materialsor other manufacturing complexities that must be considered when building your heaters. Contact your local salesrepresentative to check the current lead times offered.FAST TRACK for FIREROD ® <strong>Heater</strong>s<strong>Watlow</strong>’s FAST TRACK program for made-to-order FIREROD ® cartridge heaters allows a range of FIRERODs to beshipped in two or five days.With the FAST TRACK program, you can choose the size, voltage, wattage and termination from a predetermined set ofoptions and choose when you want it – either a two- or five-day lead time.For more information and applicable products, look for the FAST TRACK logo in the cartridge section of this catalog.WATLOW ®3

<strong>Heater</strong> Selection MatrixHeating Solids<strong>Heater</strong>TypeApplication DescriptionSheathMaterialsTypical Max. Max. OperatingWatt Densities TemperaturesW/in 2 W/cm 2 °F °C<strong>Catalog</strong>PageCartridge/Insertion<strong>Heater</strong>sThese heaters are inserted into a close fit hole (i.e. platens,dies and molds).Alloy 800Stainless steelup to 400up to 40062.062.01400100076054011Tubular<strong>Heater</strong>sThese heaters are clamped to the object to be heated,usually exterior surfaces of tanks or other process vessels orfitted into milled grooves in a platen.Flat: Alloy 800Stainless steelRound: Alloy 800Stainless steel404040406.26.26.26.2140012001600120076065087065093936161Flexible<strong>Heater</strong>sThese heaters are bonded or otherwise fastened to the part.Commonly used to heat irregular surfaces and shapes, orapplications requiring distributed wattage or limited space.PolyimideSilicone rubber20103.11.6390500200260148117High- MULTICELL heaters are loosely inserted into the platenTemperature hole for radiant heating. Can also be used in any static or<strong>Heater</strong>s dynamic non-contact application as a radiant heat source.Commonly used for extreme high temperature applications.Ceramic fiber heaters can be formed into an oversizedchamber to surround the object being heated. Using radiantand convection heat transfer, ceramic fiber heaters are usedin ovens and furnaces.Alloy 600Alloy 800Molded ceramic fiber6060309.39.34.6210021002200115011501205425433Specialty<strong>Heater</strong>sULTRAMIC ® advanced ceramic heaters are bonded orclamped to the object being heated.Thick film conduction heaters are clamped to the partbeing heated.Coil/Cable heaters can be formed to heat flat or curvedsurfaces, or wound around the object being heated. Typicalapplications include platen heating and plastic injectionmolding nozzles.Aluminum nitride 1000Dielectric glass on 430 75stainless steel substrateStainless steel orAlloy 600 3015511.64.6111210221200600550650459463467Strip/Clamp-On<strong>Heater</strong>sThese heaters are bolted or clamped to a surface (i.e.dies, molds, ovens). Often used for freeze and moistureprotection.Aluminized steel withrefractory insulationStainless steel withmineral insulation10014015.521.711001400595760481477Band/Barrel<strong>Heater</strong>sThese heaters are clamped to cylindrical surfaces (i.e.extrusion barrels and nozzles).Stainless steel withmineral insulation 100 15.5 1400 760 493Radiant<strong>Heater</strong>sThese heaters are used in any static or dynamic,non-contact application where conduction or convectionheating is not practical. Commonly used in laminatingprocesses, thermoforming and paint drying.Molded ceramic fiberStainless steelemitter strip203034.620002200109512005185144WATLOW ®

<strong>Heater</strong> Selection MatrixHeating Liquids/Surface Heating and Immersion<strong>Heater</strong>TypeCartridge/Insertion<strong>Heater</strong>sTubular<strong>Heater</strong>sApplication DescriptionThese are used as an immersion heater placed eitherdirectly in the liquid, or in a protective well (recommendedfor immersion in water or 90 plus percent water solublesolutions).These heaters are immersed directly in the liquid beingheated. Most commonly used when high kilowatts arerequired. Multiple style mounting adaptors, such as flangesand NPT fittings, provide excellent pressure boundaries.SheathMaterialsAlloy 800 Up to 300in waterFlat: Alloy 800Stainless steelRound: Alloy 800Stainless steelSteelTypical Max. Max. OperatingWatt Densities TemperaturesW/in 2 W/cm 2 °F °C60606060606046.5 212in water9.39.39.39.39.39.31400120035016001200750<strong>Catalog</strong>Page100 11760650180870650400939361616161Flexible<strong>Heater</strong>sImmersion<strong>Heater</strong>sCirculation<strong>Heater</strong>sFluidDelivery<strong>Heater</strong>sHigh-Temperature<strong>Heater</strong>sSpecialty<strong>Heater</strong>sStrip/Clamp-On<strong>Heater</strong>sThese heaters are applied to the surface of a pipe vesselcontaining a liquid (well suited for curved surfacesand irregular shaped objects; frequently used forfreeze protection).FIREBAR ® heaters have multiple elements mounted in a flangeor screw plug fitting. They are immersed directly in a fluid or ina protective well.WATROD heaters have multiple elements mounted in aflange or screw plug fitting. These are immersed directly in afluid or in a protective well.Tubular heaters have multiple elements mounted in a screwplug or ANSI flange fitting and placed in a vessel throughwhich fluid is passed. FIREBAR or WATROD elements maybe utilized.FREEFLEX ® heaters have polymeric heated tubing, used tomaintain temperature in medical applications where heatedflexible tubing is required.Syringe heaters are formed to fit a cylindrical part. Theyare often used in medical applications for heating contrastmedia and often incorporate a sensor and on-board system.Ceramic fiber assembled heaters can be used in a chambersurrounding the tank, vessel, crucible or bath. Radiant andconvection heat transfer heat the load.Coil/Cable heaters that are wrapped or wound around pipeor vessel containing a liquid can be used, or used directlyas an immersion heater. They are often used in applicationswith space limitations (i.e. photo processing equipment,scientific instruments and heat tracing).These heaters are bolted or clamped to the wall of atank or vessel. They are used in food warming and otherapplications offering a flat mounting surface.PolyimideSilicone rubberAlloy 800Alloy 800316 stainless steelSteelRound: Alloy 800Stainless steelSteelPolyimideLexanSilicone rubber2010Up to 100Up to 1006060606072 W/ft233.11.615.515.59.39.39.39.322 W/m0.310.47390500212in water212in water1400in air1600350120075021218542820026010010076087018065040010085220148117Molded ceramic fiber 30 4.6 2200 1205 433Stainless steel orAlloy 600 30 4.6 1200 650 467Aluminized steel withrefractory insulationStainless steel withmineral insulation10014015.521.711001400595760165165331385388481477Band/Barrel<strong>Heater</strong>sThese heaters are clamped to cylindrical surfaces and aremost commonly used to heat liquids flowing through pipesas freeze protection.Stainless steel withmineral insulation 100 15.5 1400 760 493WATLOW ®5

<strong>Heater</strong> Selection MatrixHeating Gases<strong>Heater</strong>TypeApplication DescriptionSheathMaterialsTypical Max. Max. OperatingWatt Densities TemperaturesW/in 2 W/cm 2 °F °C<strong>Catalog</strong>PageCartridge/Insertion<strong>Heater</strong>sThese heaters are mounted in pipes or vessels throughwhich gases pass. They can be placed in protection tubes,making access and wiring easier.Alloy 800 or stainlesssteel100 15.5 Contact <strong>Watlow</strong> 11Tubular<strong>Heater</strong>sThese heaters have multiple elements mounted in an arrayand placed in a duct or vessel through which gases pass.Flat tubular elements can be modified with the addition offins to increase surface area.Flat: Alloy 800Stainless steelRound: Alloy 800Alloy 600303030304.64.64.64.61400120016001800760650870980237Flexible<strong>Heater</strong>sThese heaters are applied to the surface of a pipe or vessel Polyimidecontaining gases. They are well suited for curved surfaces Silicone rubberand irregular shaped objects. Excellent for use in enclosures.550.80.8390500200260148117Circulation<strong>Heater</strong>sAir<strong>Heater</strong>sTubular heaters have multiple elements mounted in a screwplug or ANSI flange fitting and placed in a vessel throughwhich fluid is passed. FIREBAR or WATROD elements maybe utilized.Duct heaters have multiple elements placed in a ductthrough which gases pass.Enclosure heaters prevent freezing and condensation inelectrical and mechanical housings.Finned FIREBAR heaters have aluminized steel fins attachedto a FIREBAR element. They are used for forced air heatingand radiant heating in drivers, ovens and duct work.Finned Strip have aluminized steel fins attached to a375 heater. They are used for air heating, freeze protectionand load bank resistors.High- MULTICELL heaters have multiple elements placed in aTemperature duct or vessel through which gases pass. Designs are also<strong>Heater</strong>s available to heat a pass tube externally to isolate gas fromthe element. Excellent for use in high temperature/highpressure applications.Ceramic fiber heaters are used to construct chambers andfurnaces through which gases are passed. <strong>Heater</strong>s functionas high-temperature radiant heaters surrounding transferpipes or other special vessels.Specialty<strong>Heater</strong>sCoil/Cable heaters are sinuated or wound into coils, whichcan be inserted into a pipe or vessel to heat flowing air orgases. Cable heaters readily lend themselves to applicationswhere space is restricted.Flat: Alloy 800304 stainlesssteelRound: Alloy 800Alloy 600Alloy 800Stainless steelAluminumStainless steelAluminized steelAlloy 600Alloy 800Molded ceramic fiber3030303020 to 30155Up to 50306060304.64.64.64.63 to 4.62.30.87.74.79.39.34.61400120016001800140012001501200110021002100220076065087098076065066650595115011501205331391417419112Stainless steel orAlloy 600 30 4.6 1200 650 4674094254336WATLOW ®

<strong>Heater</strong> Selection MatrixHeating Within a Vacuum<strong>Heater</strong>TypeApplication DescriptionSheathMaterialsTypical Max. Max. OperatingWatt Densities TemperaturesW/in 2 W/cm 2 °F °C<strong>Catalog</strong>PageCartridge/Insertion<strong>Heater</strong>sThese heaters are mounted in a vacuum vessel for radiantenergy transfer.Alloy 800Stainless steelup to 35up to 355.45.41400100076053811Tubular<strong>Heater</strong>sThese heaters are mounted in a vacuum vessel for radiantenergy transfer.Flat: Alloy 800Stainless steelRound: Alloy 800Alloy 600303030304.64.64.64.6140012001600180076065087098093936161Flexible<strong>Heater</strong>sHigh-Temperature<strong>Heater</strong>sThese heaters are applied to the exterior surface of a pipe orvessel. They are well suited for curved surfaces and irregularshaped objects. Note: Polyimide is the only flexible heatertype recommended for use in the vacuum.MULTICELL heaters are mounted in a vacuum vessel forradiant energy transfer.Ceramic fiber heaters surround the exterior surface of avacuum vessel, using radiant energy for heat transfer.Polyimide 7 1.1 390 200 148Alloy 600Alloy 800Molded ceramic fiber6060309.39.34.6225022502200123012301205425433Specialty<strong>Heater</strong>sULTRAMIC advanced ceramic heaters are bonded orclamped to the object being heated.Coil/Cable heaters are wound into a coil or sinuated patternand mounted in a vacuum vessel for radiant energy transfer.Aluminum nitrideAlloy 600 orStainless steel1000201553.111121200600650459467Band/Barrel<strong>Heater</strong>sThese heaters are applied to exterior surface of a pipeor vessel.Stainless steel withmineral insulation 100 15.5 1400 760 493WATLOW ®7

8 WATLOW ®

Cartridge/Insertion <strong>Heater</strong>sMax. Operating Typical Max.Temperatures Watt DensitiesCartridge/Insertion <strong>Heater</strong>s Sheath Materials °F °C W/in 2 W/cm 2 PageFIREROD ® Alloy 800 1400 760 400 62.0Stainless steel 1000 538 400 62.011High-Temperature FIREROD Alloy 800 1800 982 100 15.5 36Metric FIREROD Alloy 800 1400 760 330 50.0 48MULTICELL Alloy 800 2050 1120 30 4.6 58Cartridge/Insertion <strong>Heater</strong>sWATLOW ®9

10 WATLOW ®

Cartridge/Insertion <strong>Heater</strong>sFIREROD ® Cartridge <strong>Heater</strong>sThe <strong>Watlow</strong> ® FIREROD ® cartridge heater incorporatesengineering excellence and is supported by almost60 years of solid industry performance across a broadrange of simple and complex applications. As the premierchoice in swaged cartridge heating, thousands ofindustrial manufacturers continue to choose <strong>Watlow</strong> astheir trusted thermal partner and certified cartridgeheater supplier.Built using premium materials and tight manufacturingcontrols, the FIREROD heater provides superior heattransfer, uniform temperatures, resistance to oxidationand corrosion and a long life even at high temperatures.Every system component that leaves our manufacturingfacilities meets our strict quality assurance specifications,in addition to those set forth by leading standards andregulating industries.To meet our customer’s individual needs, there are manydelivery options available for FIREROD heaters.Performance Capabilities• Part temperatures up to 1400°F (760°C) onalloy 800 sheath• Watt densities up to 400 W/in 2 (62 W/cm 2 )• Maximum voltage up to 480VFeatures and BenefitsNickel-chromium resistance wire• Ensures even and efficient distribution of heat tothe sheathConductor pins• Provide a metallurgical bond to the resistance wire• Ensure a trouble-free electrical connectionMagnesium oxide insulation of specific grain andpurity• Results in high dielectric strength and contributes tofaster heat-upAlloy 800 sheath• Resists oxidation and corrosion from heat, manychemicals and atmospheresMinimal spacing between the element wire andsheath• Results in lower internal temperature• Accommodates a design with fewer or smaller heatersoperating at higher watt densitiesInternational Organization for Standardization (ISO)9001 certified• Provides confidence that quality and reliabilityexpectations are metEnd PieceLead WiresLead WiresMgOInsulationUL ® and CSA approved flexible stranded wires• Lead insulation rated to temperatures up to480°F (250°C)Patented lead adapter (LA) method• Allows same day shipment on more than 150,000configurations of stock FIREROD heaters and leadcombinationsTypical ApplicationsConductorPinsNo HeatSectionSheathResistance Wire• Semiconductor chamber heating• Semiconductor wire and die bonding• Freeze protection and deicing of equipment in coldclimates or applications• Humidity control• Patient comfort heating used in medical devices• Mold die and platen heating• Seal bars used in packaging equipment• Test sample heating in gas chromatography equipmentWATLOW ®11

Cartridge/Insertion <strong>Heater</strong>sFIREROD Cartridge <strong>Heater</strong>sApplications and Technical DataTolerancesDiameter• 1 in. (25 mm) units: ±0.003 in. (±0.08 mm)• All other units: ±0.002 in. (±0.05 mm)Sheath Length• All units up to 4 1 /2 in. (114 mm) long:± 3 /32 in. (±2.4 mm)• 1 /8 in. diameter units over 4 1 /2 in. (114 mm)long: ±3%• All other units over 4 1 /2 in. (114 mm) long: ±2%Length MeasurementsPin Style and Potted FIRERODsPTFE orPotted Seal<strong>Heater</strong> LengthPTFE - Swaged-in Leads FIRERODsWattage• 1 /8 in. units: +10%, -15%• All other units: +5%, -10%Resistance• 1 /8 in. units: +15%, -10%• All other units: +10%, -5%Resistance changes with temperature. There are threecircumstances under which resistance can be measured:1. Room temperature (before use): nominal ohms are90% of Ohm’s law calculation.2. Room temperature (after use): nominal ohms are95% of Ohm’s law calculation.3. At temperature (during use): depending on applicationnominal ohms are approximately 100% of Ohm’s law.Note: Resistance and wattage values are approximatedepending on application conditions.Component Recognition File Numbers• UL ® component rated to 240VAC(file number E52951)• CSA component rated to 240VAC(file number LR7392)• VDE component rated to 240VAC(file number 10062-4911-0006)Note: Not all options or combinations of options arecovered. UL ® , CSA, VDE and CE marking is availableupon request.<strong>Heater</strong> Length (excludes lead end turnover)12WATLOW ®

Cartridge/Insertion <strong>Heater</strong>sFIREROD Cartridge <strong>Heater</strong>sApplications and Technical DataDimensional DataThis table shows minimum/maximum sheath lengths foravailable FIREROD diameters.FIREROD DiameterLengthNominal Actual Min. Max.in. in. (mm) in. (mm) in. (mm)1 /8 0.122 (3.1) 7 /8 (22.2) 12 (305)1 /4 0.246 (6.3) 7 /8 (22.2) 36 (915)3 /8 0.371 (9.4) 7 /8 (22.2) 48 (1220)1 /2 0.496 (12.6) 7 /8 (22.2) 60 (1520)5 /8 0.621 (15.8) 1 1 ⁄4 (25.0) 72 (1830)3 /4 0.746 (18.9) 1 1 ⁄4 (25.0) 72 (1830)1 0.996 (25.3) 1 1 /4 (32.0) 72 (1830)Indicates recommended maximum sheath length; however, longerlengths may be available.CamberCamber is defined as the maximum deviation of theheater’s centerline from straight. FIREROD camberwithin allowable tolerances is verified via passagethrough a cylindrical gauge of specified length anddiameter. Normally, slight camber does not presenta problem since the heater will flex enough to fit intoa straight, close-fit hole.Camber MeasurementCamberAllowable Camber Versus LengthMax. Allowable Camber (in.)0.2000.1800.1600.1400.1200.1000.0800.0600.0400.0200.0000 5 10 15 20 25 30 35 40<strong>Heater</strong> Length (in.)Max. camber = 0.020 in. x (length in feet) 2 or 0.005 in., whichever is greater.WATLOW ®13

Cartridge/Insertion <strong>Heater</strong>sFIREROD Cartridge <strong>Heater</strong>sApplications and Technical Data (Continued)Electrical DataThe table below will assist you in selecting the correctFIREROD heater for your application, accordingto available voltage, amperage and wattage.Please note, some combinations of minimum andmaximum wattages are not available on the same heaterdiameter. If your application exceeds the limitationsshown, contact your <strong>Watlow</strong> representative.Dia.1/4 in. (6 mm)NominalNo-HeatHeated Length1/4 in. (6 mm)NominalNo-Heat12 in. (305 mm)FIRERODDiameterin.Min. Watts @ 120V 3<strong>Heater</strong> LengthMax. WattsVoltsMax.AmpereMax. 11 in.(25 mm)1 1 /2 in.(38 mm)2 in.(50 mm)120V1-phase240V1-phase480V1-phase240V3-phase1 /8 240 3.1 — 8 5 360 720 — — —1 /4 240 4.4 2 100 55 40 525 1050 — — —3 /8 240 6.7 65 35 25 800 1600 — — —1 /2 240 9.7 40 25 20 1160 2320 — — —5 /8 480 23.0 35 20 15 2760 5520 11,000 5 5480V3-phase3 /4 480 23.0 30 15 10 2760 4 5520 11,000 9550 19,1001 7 480 23.0 — 15 10 2760 4 5520 11,000 9550 4 19,100 4Number Of Circuits 6Diameterin. 1-phase 3-phase3 /4 3 11 5 2a Determined by the current carrying capacity of internal parts andlead wire. Alternate material may be available.2 For 1 /4 in. (6 mm) units with thermocouple maximum amperageis 3.1A.3 Determined by the limitation of space for resistance winding.For minimum wattage of 240VAC multiply value by four.4 Higher wattages are available using more than one set of powerleads. Multiply the wattage from the table by the applicable factor.5 Contact your <strong>Watlow</strong> representative for data.6 On 3 /4 in. (19 mm) diameter units, either three single-phase circuitsor one three-phase delta or wye circuit is available. On 1 in. (25 mm)diameter units, either five single-phase or two three-phase deltacircuits are available.7 A minimum charge per line item applies.14 WATLOW ®

Cartridge/Insertion <strong>Heater</strong>sFIREROD Cartridge <strong>Heater</strong>sMaximum Allowable Watt DensityThe following four charts detail maximum allowable wattdensities for applications that use metal, steam, air or gasheating. Please review the charts and applicable data todetermine the correct watt density for your application.Correction FactorsThese graphs depict FIRERODs used in steel parts,therefore, for stainless steel, aluminum or brass, referto applicable correction factors:1. For stainless steel, enter the graph with a fit0.0015 in. (0.04 mm) larger than actual fit.2. For aluminum and brass, enter the graph with atemperature 100°F (38°C) above actual temperature.Heating MetalsThe Maximum Watt Density— Heating Metals chart willdisplay the maximum hole fit or recommended wattdensity of the heater. Enter the chart with either knownvariable, part-fit-in-hole dimension or W/in 2 . Then, find theapplication temperature by reading up or over onthe chart.If the fit of the heater in the hole dimension is not known,it can be easily determined. Subtract the minimumdiameter of the FIREROD (nominal diameter minustolerance) from the maximum hole diameter. For example,the hole fit is 0.006 in. (0.15 mm) for a hole diameter of0.500 in. (13 mm) minus a heater diameter of 0.496 in.(12.6 mm) ±0.002 in. (0.05 mm). For FIREROD heaters insquare holes or grooves, contact your <strong>Watlow</strong>representative for the fit in hole dimension.0.1000.0900.0800.0700.0600.050Maximum Allowable Watt Density—Heating MetalsHoleFit0.040Cartridge <strong>Heater</strong>0.030Fit in Hole—in.0.0200.0100.0090.0080.0070.0060.005Fit in hole = maximum hole I.D. minusminimum heater O.D.200°F (93°C)400°F (204°C)1000°F (538°C)800°F (427°C)600°F (316°C)0.0041200°F (649°C)1400°F (760°C)0.0030.0020.00110 20 30 40 50 60 70 80 100 200 300 400 500 600 800 1000Watt Density—W/in 2WATLOW ®15

Cartridge/Insertion <strong>Heater</strong>sFIREROD Cartridge <strong>Heater</strong>sMaximum Allowable Watt Density (Continued)Watt Density vs. Ambient Air TemperatureThe Watt Density vs. Ambient Air Temperature graphshows the maximum allowable watt density when oneFIREROD is operated in air or similar gas.For FIRERODs grouped in a single row, with no less thanone diameter between elements, multiply value from thegraph by 0.95. When a reflector is placed behind theheaters, multiply the maximum allowable watt densityvalue from the graph by 0.85.Ambient Temperature—°F1600140012001000800600400Maximum Allowable WattDensity vs. Ambient Air20010 20 30 40 50 60Watt Density—W/in 2Sheath Temperature in Ambient AirThe Sheath Temperature in Ambient Air graph indicatesthe watt density required to bring a pre-oxidizedFIREROD to a given sheath temperature whenoperated in 70°F (21°C) ambient air.At 44 W/in 2 (6.8 W/cm 2 ), the sheath temperature is1450°F (784°C). At this temperature, a one-year life isexpected if cycling is not too frequent.Higher temperatures result in reduced heater life.FIREROD Sheath Temperature—°F200015001000500FIRERODSheath Temperature WhenOperated in 70°F Ambient AirNot Pre-oxidizedPre-oxidized10 20 30 40 50 60Watt Density—W/in 2Watt Density in Moving AirThe Watt Density in Moving Air graph shows themaximum allowable watt density of a FIREROD inmoving air.The air movement is expressed in feet per minute (FPM).If the air flow is known in cubic feet per minute (CFM),divide the CFM by the net-free area around the heater(ft 2 ). The net-free area is the total area of the enclosureminus the area occupied by the heater.Air Velocity Past <strong>Heater</strong>—FPM45004000350030002500200015001000Entering AirUp To 200°FMaximum AllowableWatt Density in Moving AirFIREROD–Parallel To Air FlowFIREROD–Perpendicular To Air Flow50020 40 60 80 100 120Watt Density—W/in 216 WATLOW ®140

Cartridge/Insertion <strong>Heater</strong>sFIREROD Cartridge <strong>Heater</strong>sLead and Diameter InformationStandard Lead Specifications<strong>Heater</strong>Diameterin. (mm)Max.VoltageStandardLead GaugeFiberglassSize ToleranceFiberglassStandardLead GaugePTFESizeTolerancePTFEStainless SteelHoseI.D.Stainless SteelBraidI.D.1 /8 (3) 300 24 0.044 - 0.058 24 solid 0.036 - 0.044 1 /8 1 /81 /4 (6) 300 22 0.066 - 0.078 22 0.050 - 0.058 5 /32 1 /83 /8 (10) 300 22 0.076 - 0.088 20 0.056 - 0.064 7 /32 3 /161 /2 (13) 300 18 0.089 - 0.101 20 0.074 - 0.084 9 /32 1 /45 /8 (16) 600 18 0.108 - 0.124 18 0.097 - 0.113 7 /16 3 /83 /4 (19) 600 18 0.108 - 0.124 14 0.097 - 0.113 7 /16 3 /81 (25)1 600 18 0.095 - 0.109 14 0.087 - 0.101 N/A N/ALead length tolerances:1 to 36 in. (25 to 914 mm) = - 1 /2 in. (13 mm), +1 1 /2 in. (38 mm)> 36 to 72 in. (914 to 1829 mm) = -1, +3 in. (-25 + 76 mm) 1Stainless steel hose and braid tolerances: same as lead wire.Units constructed with 480V require MGT or PTFE leads. If connectingheaters in series above 300V, MGT leads are also required.Ratings: GGS, 300V, 482°F (250°C)MGT, 600V, 842°F (450°C)PTFE, 600V, 392°F (200°C)Silicone rubber, 600V, 302°F (150°C)1 A minimum charge per line item applies.Additional Lead SpecificationsLead Gauge Nickel Ampacity N.C.C. Ampacity SPC/NPC26 2.5 4.2 6.024 stranded 3.1 5.2 7.524 solid 3.1 5.2 7.522 4.4 7.2 10.520 N/A N/A 14.018 7.6 12.6 18.016 9.7 16.1 23.014 12.5 21.0 30.012 16.8 28.0 40.010 23.0 38.5 55.0WATLOW ®17

Cartridge/Insertion <strong>Heater</strong>sFIREROD Cartridge <strong>Heater</strong>sLead Adapter (LA)OptionsPatented LA Modification MethodThe lead adapter (LA) modification process is a powerfultool for providing a wide range of finished heaterconfigurations very quickly. The LA process allows thebase FIREROD heater to be modified into a multitudeof configurations. The base FIREROD heater can beselected to meet customers’ individual needs. The baseheater can then be customized by adding various finishingoptions like lead length, lead protection, flanges, locatingrings and right-angle constructions.Right AngleSwaged-in Flexible LeadsNo-Heat ExtensionsPTFE Seal and LeadsSilicone Rubber Seal and LeadsFlangeLocating RingThreaded FittingStainless Steel BraidStainless Steel HoseRight AngleStainlessSteel HoseRight AngleStainlessSteel Braid18 WATLOW ®

Cartridge/Insertion <strong>Heater</strong>sFIREROD Cartridge <strong>Heater</strong>sLead Adapter (LA)OptionsTwo- or Five-Day Lead Times<strong>Watlow</strong>’s FAST TRACK program allows made-to-order FIREROD cartridge heaters to be shipped in two or five days. Youcan design a FIREROD to meet your unique applications. You can choose the size, voltage, wattage, terminationoptions and your preferred lead time. To take advantage of this program contact your <strong>Watlow</strong> representative.Options 1 /4 Inch 3 /8 Inch 1 /2 Inch 5 /8 Inch 3 /4 InchSwaged-in leads 3 3 3 3 3PTFE seal and leads 3 3 3 3Right angle leads 3 3 3 3 3Stainless steel hose 3 3 3 3 3Right angle hose 3 3 3 3Stainless steel braid 3 3 3 3 3Right angle braid 3 3 3 3Straight hose with PTFE seal and leads 3 3 3 3Right angle hose with PTFE seal and leads 3 3 3 3Straight braid with PTFE seal and leads 3 3 3 3Right angle braid with PTFE seal and leads 3 3 3 3Right angle PTFE seal and leads 3 3 3 3Ground lead 3 3 3 3 3FS flange 3 3 3FM flange 3 3 3 3 3FL flange 3 3Single stainless steel fitting 3 3 3 3 3Additional lead end no-heat length 3 3 3 3 3Note: Maximum heater length is 24 inches.WATLOW ®19

Cartridge/Insertion <strong>Heater</strong>sFIREROD Cartridge <strong>Heater</strong>sLATermination OptionsLA Swaged-in Flexible LeadsLA PTFE Seal and LeadsMin. No-Heat1 in.(25 mm)Min. No-Heat1/2in.(13 mm)LA swaged-in flexible leads are used in applicationswhere a high degree of flexing exists or the leads mustbe bent sharply adjacent to the heater without exposingor breaking the conductor. The stranded wire leadsare connected internally and exit through the lead end.The overall length of the heater is extended by1 /4 in. (6 mm). To order, specify length adder code Ebringing the total lead end no-heat to 1 /2 in. (13 mm).This LA option is not available on 1 /8 in. (3 mm) diameterFIRERODs. On 1 /8 in. (3 mm) diameter FIRERODs, leadsare connected externally using a solid conductor leadwire. If stranded wire is desired on 1 /8 in. (3 mm) diameterunits, contact your <strong>Watlow</strong> representative.The LA PTFE seal and leads protect the heater againstmoisture/contamination from lubricating oil, cleaningsolvents, plastic material or fumes and organic tapes.This seal is effective to 392°F (200°C) under continuousoperation.Please note when ordering this option, that a minimumno-heat section is required to allow for construction.Additional no-heat may be required to keep the sealbelow effective temperatures. The minimum lead endno-heat required is 1 in. (25 mm). The LA cap adds3 /4 in. (19 mm) to the overall length of the heater. Toorder, specify option code T.LA Silicone Rubber Seal and LeadsNo-Heat ExtensionsMin. No-Heat1 in.(25 mm)Right Angle (Swaged-in) LeadsSwaged-in LeadsNo-HeatLengthNo-HeatLengthNo-heat extensions are recommended in applicationswhere leads may be exposed to excessive heat andrequire a cooler lead end. They are also used when heatis not required along the entire length of the FIREROD.No-heat extensions are available for most LA options indiameters of 3 /8, 1 /2, 5 /8 and 3 /4 in. (10, 13, 16 and 19mm). These extensions are designed to provide a totalno-heat length of 1, 1 1 /2, 2 or 2 1 /2 in. (25, 38, 51 or 65mm) at the lead end of FIRERODs only. Contact your<strong>Watlow</strong> representative for available LA options.The LA silicone rubber seal and leads protect the heateragainst moisture and contamination from lubricating oil,cleaning solvents, plastic material, fumes and organictapes. This seal is effective to 302°F (150°C) undercontinuous operation.Please note when ordering this option, that a minimumno-heat section is required to allow for construction.Additional no-heat may be required to keep the sealbelow effective temperatures. The minimum lead endno-heat required is 1 in. (25 mm). The LA cap adds3 /4 in. (19 mm) to the overall length. To order, specifyoption code P.20 WATLOW ®

Cartridge/Insertion <strong>Heater</strong>sMin. No-HeatFIREROD Cartridge <strong>Heater</strong>sLATermination Options (Continued)1 in.(25 mm)LA Straight Stainless Steel HoseMin. No-HeatMin. No-HeatMin. No-Heat1 in.(25 mm)LA Straight Stainless Steel BraidMin. No-HeatAn LA straight stainless steel hose provides the bestprotection against abrasion from sharp edges. It alsooffers ease of handling and wiring in abrasiveenvironments. Unless specified a 12 in. (305 mm)hose is supplied. Leads are 2 in. (51 mm) longerthan the hose but, longer leads are available.The minimum lead end no-heat required is 3 /4 in.(19 mm). This option adds 1 /2 in. (13 mm) to the overalllength. To order, specify option code H.Min. No-HeatThe LA straight stainless steel braid is designed to protectleads from abrasion against sharp edges. It is the mostMin. No-Heatflexible <strong>Watlow</strong> protective lead arrangement.Unless specified, a 12 in. (305 mm) braid is supplied.Leads are 2 in. (51 mm) Min. longer No-Heat than the braid, but longerleads are available.The minimum lead end no-heat required is 3 /4 in.(19 mm). This option adds 1 /2 in. (13 mm) to the overalllength. To order, specify option code C.LA Straight Stainless Steel Hose withPTFE Leads and SealLA Straight Stainless Steel Braid withPTFE Leads and SealMin. No-HeatAn LA straight stainless steel hose with PTFE leads andseal is the ultimate combination for providing abrasionprotection and a moisture resistant seal. Unless specified,a standard 12 in. (305 mm) hose is supplied. Leads are2 in. (51 mm) longer than the hose, but longer leads areavailable. This seal is effective up to 392°F (200°C) undercontinuous operation.The minimum lead end no-heat required is 1 in. (25 mm).This option adds 3 /4 in. (19 mm) to the overall length. Toorder, specify option code G.Min. No-HeatThe LA straight stainless steel braid with PTFE leads andseal is <strong>Watlow</strong>’s most flexible lead protection witha moisture resistant seal. Unless specified, a 12 in.(305 mm) braid is supplied. Leads are 2 in. (51 mm)longer than the braid, but longer leads are available.This seal is effective up to 392°F (200°C) undercontinuous operation.The minimum lead end no-heat required is 1 in. (25 mm).This option adds 3 /4 in. (19 mm) to the overall length. Toorder, specify option code F.WATLOW ®21

Cartridge/Insertion <strong>Heater</strong>sFIREROD Cartridge <strong>Heater</strong>sLARight Angle OptionsLA Right Angle LeadsLA Right Angle Stainless Steel Hose withPTFE Leads and SealMin. No-HeatLA right angle leads are used in applications with a highdegree of flexing and when space limitations are critical.Stranded lead wires are connected internally (swaged-in)and exit at a 90 degree angle at the end of the heater.To order, specify option code R.Minimum No-Heat RequiredMin. No-Heat in. (mm)Dia. 1 /4 3 /8 1 /2 5 /8 3 /4In. (mm) 13 /16 (21) 3 /4 (19) 13 /16 (21) 13 /16 (21) 13 /16 (21)Min. No-HeatTo order right angle leads with PTFE leads and seals,specify option code B.LA Right Angle Stainless Steel HoseMin. No-Heat1½ in.(38 mm)An LA right angle stainless steel hose with PTFE leadsand a seal is the ultimate combination for providingabrasion protection and a moisture resistant seal withwiring convenience. Unless specified, a 12 in. (305 mm)hose is supplied. Leads are 2 in. (51 mm) longer than thehose but longer leads are available. This seal is effectiveto 392°F (200°C) under continuous operation.The minimum lead end no-heat required is 1 1 /2 in.(38 mm). This option adds 1 1 /4 in. (32 mm) to overalllength on stock units.To order, specify option code M.Note: This option is not available on 1 /4 in. (6 mm)diameter.Min. No-Heat1 in.(25 mm)An LA right angle stainless steel hose is provided forwiring convenience. Like the LA straight stainless steelhose, it protects leads from abrasion against sharp edges.Unless specified, a 12 in. (305 mm) hose is supplied.Leads are 2 in. (51 mm) longer than the hose, but longerleads are available.Diameter 3 /81 /25 /83 /4Adder length in. (mm) 3 /4 (19) 3 /4 (19) 3 /4 (19) 7 /8 (22)Min. no-heat in. (mm) Min. No-Heat 1 (25) 1 (25) 1 (25) 1 1 /8 (29)To order specify option code W.Note: This option is not available on 1 /4 in. (6 mm)diameter.22 WATLOW ®

Cartridge/Insertion <strong>Heater</strong>sFIREROD Cartridge <strong>Heater</strong>sLARight Angle Options (Continued)LA Right Angle Stainless Steel BraidMounting OptionsLA Stainless Steel Threaded FittingsStandard Fitting LocationAAn LA right angle stainless steel braid is provided forwiring convenience. It protects leads from abrasionagainst sharp edges.Unless specified, a 12 in. (305 mm) braid is supplied.Leads are 2 in. (51 mm) longer than the braid, but longerleads are available.Diameter Min. No-Heat/8 1 /2 5 /8 3 /4Adder length in. (mm) 3 /4 (19) 3 /4 (19) 3 /4 (19) 7 /8 (22)Min. no-heat in. (mm) 1 (25) 1 (25) 1 (25) 1 /8 (3)Min. No-HeatTo order, specify option code Y.Note: This option is not available on 1 /4 in. (6 mm)diameter.Min. No-HeatMin. No-HeatMin. No-Heat1 in.(25 mm)LA Right Angle Stainless Steel Braid withPTFE Leads and Seal1½ in.(38 mm)The LA right angle stainless steel braid with PTFE leadsand seal is <strong>Watlow</strong>’s most flexible lead protection witha moisture resistant PTFE seal and wiring convenience.Unless specified, a 12 in. (305 mm) braid is supplied.Leads are 2 in. (51 mm) longer than the braid, but longerleads are available. This seal is effective up to 392°F(200°C) under continuous operation.The minimum lead end no-heat required is 1 1 /2 in.(38 mm). This option adds 1 1 /4 in. (32 mm) to theoverall length on stock units.To order, specify option code A.Note: This option is not available on 1 /4 in. (6 mm)diameter.Fitting overlaps the unheated section and is silver soldered tothe sheath.Threaded fittings allow fast, water-tight installation ofthe heater into a threaded hole. These fittings are 304stainless steel, other stainless steel alloys are availableupon request. Double threaded fittings are also available.Minimum UnheatedPlease see page 33 for threaded fitting specifications.Provide the location of the fittings if no-heat extensionoption is requested. Specify the location for option B.LeadArrangementCrimped LeadsSwaged-in LeadsSTR SS HoseSTR SS BraidPTFE Seal & LeadsSilicone Seal & LeadsOptional Fitting LocationStandard Fitting 1LocationDimension Ain. (mm)1 /4 (6)5 /16 bd (8)1 /2 c (13)1 /2 (13)7 /8 (22)7 /8 (22)a The location of the threaded fitting from the thread end of the fittingto the lead end of the heater.All optional fitting locations are available only with LA no-heatextensions. Contact your <strong>Watlow</strong> representative for details.b On 1 /4 in. diameter FIREROD only “A” dimension is 7 /16 in. (11.1 mm).c On 1 /4 in. diameter FIREROD only “A” dimension is 5 /8 in. (15.9 mm).4 On 5 /8 in. and 3 /4 in. the fitting is located at 7 /8 in. from the lead endusing a 3 /4 in. no-heat extension. In order to locate at 5 /16 in., thefitting must be epoxied.BWATLOW ®23

Cartridge/Insertion <strong>Heater</strong>sFIREROD Cartridge <strong>Heater</strong>sLAMounting OptionsFlanges1⁄16 in. (1.6 mm)(nominal)Locating Ring0.14 in. (3.6 mm)C DHStainless steel flanges are a convenient mounting methodto position a heater within an application. The flange isstaked on and located 1 /4 in. (6 mm) from the lead end.The flange can be located up to 2 1 /4 in. (57 mm) from thelead end if it is over a no-heat section. Use this option incombination with most LA configurations.To order, specify flange, size and locations.Flange SpecificationsFIRERODin. (mm)Diameter Flangein. Size D C H1 /4, 3 /8, 1 /2 FS 1 (25) 3 /4 (19) 0.144 (4)1 /4, 3 /8, 1 /2/8, 3 /4FM 1 1 /2 (38) 1 1 /8 (29) 0.156 (4)5 /8, 3 /4 FL 2 (51) 1 1 /2 (38) 0.201 (5)A stainless steel locating ring can be used as a retainingcollar to position a FIREROD if mounting requirements arenot critical.For LA, specify the location if the no-heat extensionoption is requested. On FIRERODs with crimped on leadswithout the LA option, the locating ring will be located onthe last 1 /4 in. (6 mm).To order, specify locating ring.Locating Ring SpecificationsDiameter 1 /4 3 /8 1 /2 5 /8 3 /4Ring O.D.in. (mm) 1 /2 (13) 5 /8 (16) 3 /4 (19) 7 /8 (22) 1 (25)24 WATLOW ®

Cartridge/Insertion <strong>Heater</strong>sFIREROD Cartridge <strong>Heater</strong>sLAMineral Insulated (MI) Leads"Metal toMetal Seal"304 SS SheathMineral InsulationNickel ConductorTransitionPTFE LeadsMI leads handle both high temperatures andcontamination, and resist other problems includingabrasion and excessive vibration. The metal seal andswaged-in formable MI cable leads can handletemperatures up to 1500°F (815°C). The lead endseal resists moisture and other forms of contamination,including gases, oils, plastic drool, solvents and water.This LA option is also available as a manufactureditem. Specify MI leads and seal, as well as volts, watts,cable length, lead length and type. Unless specified,6 in. (152 mm) of MI cable and 12 in. (305 mm) of PTFEleads will be supplied. To order, specify option code J.Note: A minimum charge per line item applies.Benefits• Increases heater life• Minimizes down time• Resists moisture contamination• Allows a cartridge heater to be used where it was notpreviously possible• Resists abrasion and vibration• Forms and bends to fit the contours of wiring raceways• Protects against high temperatures without additionalinsulationTypical Applications• Vacuum forming• Plastic molding• Medical device manufacturing• Food handling equipment• Zinc die-castingTechnical DataMax. temp. of cable: 1500°F (815°C)Max. temp. of cable to lead transition: 300°F (149°C)(where flexible leads attach to cable)Cable sheath material: 304 SSConductor material: nickelMax. voltage: 240VLead TypesPTFE 392°F (200°C) – T<strong>Heater</strong> Max. Conductor Cable Transition Cable Length Max.Diameter Current Diameter Diameter Diameter Min. Max. Min. Voltage Lengthin. Amperes in. in. in. in. Bend Radius in. Adder3 /8 7.0 0.044 0.108 0.230 6 72 0.225 240 G ( 3 /8)1 /2 7.0 0.044 0.108 0.230 6 72 0.225 240 K ( 9 /16)5 /8 9.7 0.062 0.138 0.250 6 72 0.280 240 L ( 5 /8)3 /4 9.7 0.062 0.138 0.250 6 72 0.280 240 L ( 5 /8)This information pertains to standard FIREROD heaters.WATLOW ®25

Cartridge/Insertion <strong>Heater</strong>sFIREROD Cartridge <strong>Heater</strong>sLA OptionsMinimum Length Adders Per Diameter Per OptionOptionOption in. (mm) Code<strong>Heater</strong> Diameter 1 /4 (6) 3 /8 (9.5) 1 /2 (13) 5 /8 (15.9) 3 /4 (19)Swaged-in leads E 1 /4 (6) E 1 /4 (6) E 1 /4 (6) E 1 /4 (6) E 1 /4 (6) NoneRight angle leads K 9 /16 (14) J 1 /2 (13) K 9 /16 (14) K 9 /16 (14) K 9 /16 (14) RPTFE seal and leads — — N 3 /4 (19) N 3 /4 (19) N 3 /4 (19) N 3 /4 (19) TRight angle PTFE seal and leads — — N 3 /4 (19) N 3 /4 (19) N 3 /4 (19) N 3 /4 (19) BSilicone seal and leads — — N 3 /4 (19) N 3 /4 (19) N 3 /4 (19) N 3 /4 (19) PStraight hose J 1 /2 (13) J 1 /2 (13) J 1 /2 (13) J 1 /2 (13) J 1 /2 (13) HRight angle hose — — N 3 /4 (19) N 3 /4 (19) N 3 /4 (19) R 7 /8 (22.2) WStraight hose with PTFE seal and leads — — N 3 /4 (19) N 3 /4 (19) N 3 /4 (19) N 3 /4 (19) GStraight braid J 1 /2 (13) J 1 /2 (13) J 1 /2 (13) J 1 /2 (13) J 1 /2 (13) CRight angle braid — — N 3 /4 (19) N 3 /4 (19) N 3 /4 (19) R 7 /8 (22) YRight angle braid with PTFE seal and leads — — 1E 1 1 /4 (32) 1E 1 1 /4 (32) 1E 1 1 /4 (32) 1E 1 1 /4 (32) AStraight braid with PTFE seal and leads — — N 3 /4 (19) N 3 /4 (19) N 3 /4 (19) N 3 /4 (19) FRight angle hose with PTFE seal and leads — — 1E 1 1 /4 (32) 1E 1 1 /4 (32) 1E 1 1 /4 (32) 1E 1 1 /4 (32) MLA options are available for all FIRERODs, except the1 /8 in. diameter size. To order any of these options,please build the order number by specifying the <strong>Watlow</strong>part number, length adder code, option code and leadlength.Ordering Example: The order numberJ12A89-N72W74 indicates an order for a 12 in.(305 mm) FIREROD with 72 in. (1830 mm) right anglestainless steel hose and 74 in. (1880 mm) leads. Theoverall heater length equals 12 3 /4 in. (324 mm).Note: No-heat extensions are available for most LAoptions in diameters of 3 /8, 1 /2, 5 /8 and 3 /4 in. Contactyour <strong>Watlow</strong> representative for available LA options.To order any of these dimensions, please specify theapplicable length adder code shown.No-Heat Length Adder CodesNo-HeatOptionLengthin. (mm) Adder Code1 3 /4 (19) N1 1 /4 (32) 1E1 3 /4 (44) 1N2 1 /4 (56) 2E26 WATLOW ®

Cartridge/Insertion <strong>Heater</strong>sFIREROD Cartridge <strong>Heater</strong>sNon-Lead Adapter (LA)Modification Coding<strong>Watlow</strong> offers heaters in various diameters, lengths andvolt-wattage combinations that are ready for shipping.Basic modifications can be made and heaters are shippedthe same day. Modifications include flanges, threadedfittings, locating rings, ceramic beads and crimped onleads. Following is a list of all available non-LA mountingand pin option codes.Mounting Option CodesBA - Small flange FS (available on 1 /4, 3 /8 and 1 /2 in.)BB - Medium flange FM (available on 1 /4, 3 /8, 1 /2, 5 /8 and3 /4 in.)BC - Large flange FL (available on 5 /8 and 3 /4 in.)BD - Locating ring (available on 1 /4, 3 /8, 1 /2, 5 /8 and3 /4 in.)BG - Single stainless steel fittingBH - Double stainless steel fittingBY - Stainless steel reversedPin Option CodesAA - Short pins 3 /8 in. (10 mm)AB - Medium pins 5 /8 in. (16 mm)AC - Long pins 1 3 /4 in. (45 mm)AD - Stagger pinsAE - Ceramic beads 1 /2 in. (13 mm)AF - Ceramic beads 3 /4 in. (19 mm)AG - Ceramic beads 1 in. (25 mm)AH - Ceramic beads 1 1 /4 in. (32 mm)AJ - Ceramic beads 1 1 /2 in. (38 mm)Crimped-on LeadsCeramic BeadsLocating RingThreaded FittingWATLOW ®27

Cartridge/Insertion <strong>Heater</strong>sFIREROD Cartridge <strong>Heater</strong>sMade-to-OrderStraight OptionsSwaged-in Flexible Leads1 in. (25 mm) Min. No-HeatStraight Stainless Steel Hose1¼ in. (32 mm)Min. No-Heat¼ in. (6 mm)No-Heat12 in. (305 mm)Standard¼ in. (6 mm)No-HeatSwaged-in flexible leads are used in applications wherea high degree of flexing exists or leads must be bentsharply adjacent to the heater without exposing orbreaking the conductor. Stranded wire leads areconnected internally and exit through the lead end.Lead wire type is high temperature fiberglass. Themaximum temperature of the standard fiberglass endpiece is 842°F (450°C). Unless specified, 12 in. (305 mm)leads are supplied.The minimum lead end for no-heat is 1 in. (25 mm) min.or 12 percent of overall heater length. Additional no-heatmay be required to keep the end piece and leads belowthe maximum operating temperatures.PTFE Seal and Leads1 in. (25 mm)Min. No-Heat¼ in. (6 mm) No-HeatA PTFE seal and leads protect the heater againstmoisture and contamination from cleaning solvents,plastic material, fumes and organic tapes. This seal iseffective up to 392°F (200°C) under continuous operation.The PTFE seal and leads have a minimum lead endunheated section of 1 in. (25 mm). Additional no-heat maybe required to keep the seal below its maximum operatingtemperature.A straight stainless steel hose provides the bestprotection against abrasion from sharp edges. Italso offers ease of handling and wiring in abrasiveenvironments.Unless specified, a 12 in. (305 mm) hose is supplied.Leads are 2 in. (51 mm) longer than the hose.Option adds 1 /4 in. (6 mm) to overall length of heater.Note: This option is available with PTFE leads and seal.Minimum no-heats are longer. Contact your <strong>Watlow</strong>representative for details.Straight Stainless Steel Braid1¼ in. (32 mm)Min. No-Heat¼ in. (6 mm)No-HeatA straight stainless braid is designed to protect leadsfrom abrasion against sharp edges and is <strong>Watlow</strong>’s mostflexible protective lead arrangement.Unless specified, a 12 in. (305 mm) braid is supplied.Leads are 2 in. (51 mm) longer than the braid.This option adds 1 /4 in. (6 mm) to overall length of heater.Note: This option is available with PTFE leads and seal.Minimum no-heats are longer. Contact your <strong>Watlow</strong>representative for details.28 WATLOW ®

Cartridge/Insertion <strong>Heater</strong>sFIREROD Cartridge <strong>Heater</strong>sMade-to-OrderRight Angle OptionsRight Angle LeadsAdder LengthMin. No-HeatRight Angle Stainless Steel BraidAdder LengthMin. No-Heat¼ in. (6 mm)No-Heat¼ in. (6 mm)No-HeatRight angle leads are used in applications with a highdegree of flexing and when space limitations are critical.Standard lead wires are connected internally (swaged-in)and exit at a 90° angle at the end of the heater.Diameter 1 /4 3 /8 1 /2 5 /8 3 /4Adder length in. (mm) 1 /4 (6) 1 /4 (6) 5 /16 (8) 7 /16 (11) 7 /16 (11)Min. no-heat in. (mm) 1 1 /4 (32) 1 1 /4 (32) 1 5 /16 (33) 1 7 /16 (37) 1 7 /16 (37)Note: This option is available with PTFE leads and seal.Minimum no-heats are longer. Contact your <strong>Watlow</strong>representative for details.Right Angle Stainless Steel HoseA right angle stainless steel braid is provided for wiringconvenience. It protects leads from abrasion againstsharp edges.Unless specified, a 12 in. (305 mm) hose is supplied.Leads are 2 in. (51 mm) longer than the hose.Diameter 1 /4 3 /8 1 /2 5 /8 3 /4Adder length in. (mm) 5 /16 (8) 3 /8 (10) 9 /16 (14) 11 /16 (17) 13 /16 (21)Min. no-heat in. (mm) 1 5 /16 (33) 1 3 /8 (35) 1 9 /16 (40) 1 11 /16 (43) 1 13 /16 (46)Note: This option is available with PTFE leads and seal.Minimum no-heats are longer. Contact your <strong>Watlow</strong>representative for details.Adder LengthMin. No-Heat¼ in. (6 mm)No-HeatA right angle stainless steel hose is provided for wiringconvenience. It protects leads from abrasion againstsharp edges.Unless specified, a 12 in. (305 mm) hose is supplied.Leads are 2 in. (51 mm) longer than the hose.Diameter 1 /43 /81 /25 /83 /4Adder length in. (mm) 5 /16 (8) 3 /8 (10) 9 /16 (14) 11 /16 (17) 13 /16 (21)Min. no-heat in. (mm) 1 5 /16 (33) 1 3 /8 (35) 1 9 /16 (40) 1 11 /16 (43) 1 13 /16 (46)Note: This option is available with PTFE leads and seal.Minimum no-heats are longer. Contact your <strong>Watlow</strong>representative for details.WATLOW ®29

Cartridge/Insertion <strong>Heater</strong>sFIREROD Cartridge <strong>Heater</strong>sMade-to-OrderTermination OptionsSilicone Rubber Seal and LeadsPost TerminalsMin. No-Heat1 in.(25 mm)Made-to-order silicone rubber seal and leads protectthe heater against moisture and contamination fromlubricating oil, cleaning solvents, plastic material, fumesand organic tapes. This seal is effective up to 302°F(150°C) under continuous operation.Silicone rubber seal and leads for made-to-order unitsgreater than 10 in. (250 mm) long comprise a minimumno-heat section of approximately 12 percent of theoverall length. Longer no-heat sections are availableif required.¾ in.(19 mm)½ in. 5⁄8 in.(13 mm) (15.9 mm)Post terminals provide a quick, secure connectionwith ring or fork connectors or bus bars. Threaded6-32 studs are soldered to the solid power pins.Nuts and washers are provided.Post terminals are available on FIREROD heaters of5 /8, 3 /4 and 1 in. (16, 19 and 25 mm) diameter. On 1 in.(25 mm) diameters, pins are straight. To order, specifypost terminals.Epoxy SealUL ® Listed PlugsMin. No-Heat1 in.(25 mm)Epoxy seals help protect the heater againstmoisture and contamination from lubricating oil, cleaningsolvents, plastic material, fumes and organic tapes.These seals are effective up to 250°F (121°C) undercontinuous operation.Epoxy seals can be ordered only on units greater than1 /8 in. (3 mm) in diameter with crimped on leads. Theminimum no-heat section at the lead end is 1 in. (25 mm).Longer no-heat sections are available upon request.To order, specify epoxy seal.UL ® listed plugs are a safe, convenient installationmethod, especially when frequent connection ordisconnection is required. These plugs have a nylondead front, a molded-in cord grip and straight orTwist-Lock ® blades with or without ground.Use UL ® listed plugs with a stainless steel hose, conduit,braid or lead wires with sleeving. To order, specifyUL ® listed plugs.Ceramic Bead InsulationGround LeadGround leads are a safety feature to protect both workersand equipment. This configuration is not available on alloptions. Contact your <strong>Watlow</strong> representative for additionalinformation. To order, specify ground lead.Ceramic bead insulation protects the leads from highambient temperatures above 842°F (450°C).The beads fit over solid conductors that extend to reacha cooler area where flexible wires can be attached.This option is not available on 1 /8 in. (3 mm) diameterleads. The maximum available length on FIRERODs is12 in. (305 mm). To order, specify ceramic beads andlength, and additional lead length.30 WATLOW ®

Cartridge/Insertion <strong>Heater</strong>sFIREROD Cartridge <strong>Heater</strong>sMade-to-OrderOptionsPassivationDuring the manufacturing and handling of stainless steel,particles of iron or tool steel may embed in the sheath. Ifthey are not removed, particles may corrode and producerust spots. In critical sheath contact applications for themedical industry, passivation will remove free iron fromthe sheath. To order, specify 316L stainless steelsheath and passivation.Note: A minimum charge per line item applies.Thermocouple TypesASTM Conductor Characteristics Temperature RangeCode Positive Negative °F (°C)J Iron Constantan(Magnetic) (Non-Magnetic) 0 to 1400 (-20 to 760)(White)(Red)K Chromel ® Alumel ®(Non-Magnetic) (Magnetic) 0 to 2300 (-20 to 1260)(Yellow) (Red)For other ISA types, contact your <strong>Watlow</strong> representative.Style AStyle BStyle C1/2 in.(13 mm)No-HeatIndividually Controlled Heat ZonesIndividually controlled heat zones offer the flexibility tocontrol temperature by zones, along the length of theFIREROD heater. This is an advantage for heatingrequirements of certain applications, such as seal bars.This internal construction can be ordered on 5 /8, 3 /4 and1 in. (16, 19 and 25 mm) diameter FIREROD heaters.To order, specify individually controlled heat zonesand wattage and length per zone.Note: A minimum charge per line item applies.Internal ThermocoupleStyle A internal thermocouples can be used toevaluate heat transfer efficiency of an application. Thismeasurement can help to cut energy costs and increaseheater life. The ungrounded junction is located in theheater core to monitor the internal temperature ofthe heater.The Style B internal thermocouple provides a goodapproximation of part temperature and is locatedanywhere along the length of the heater. Due to variationsin production, this style may be grounded or ungrounded.This junction is located adjacent to the inside heatersheath in the center of the heated section unlessotherwise specified. A 1 /2 in. (13 mm) unheated sectionis required.A Style C internal thermocouple is useful in applicationswhere material flows past the end of the heater, asin plastic molding. This grounded junction is embedded ina special end disc. Unless requested, the disc end isnot mechanically sealed.To order, specify internal thermocouple, Style A, Bor C and thermocouple ASTM Type J or K.If not specified, 12 in. (305 mm) thermocouple leadsare supplied.AvailabilityAll styles are available on all diameters with the exceptionof 1 /8 in. (3.2 mm) diameter, which is available only withStyle C, and 1 in. (25 mm) which is available only withStyle A and B.WATLOW ®31

Cartridge/Insertion <strong>Heater</strong>sFIREROD Cartridge <strong>Heater</strong>sMade-to-OrderOptionsDistributed Wattage1/4 in. (6 mm)No-HeatDistributed wattage varies the watt density alongthe length of the heater. This construction techniquecompensates for heat losses along the edges of heatedparts and is ideal for seal bar applications.To order, specify distributed wattage and give thelength and wattage for each section.Note: A minimum charge per line item applies.Dual VoltageHeatedLength1/4 in. (6 mm)No-HeatWhen the FIREROD requires the flexibility of operating ontwo voltages, dual voltage internal construction should beused. Dual voltage is not compatible for all lead options.Contact your <strong>Watlow</strong> representative for availability. Toorder, specify dual voltage and voltage requirements.Note: A minimum charge per line item applies.Centerless GrindingCenterless grinding can be used to furnish precisiondiameters to permit closer heater-to-part fit allowinghigher watt densities to be used.For centerless ground heaters, the heater must havePTFE seal and leads (maximum 12 in. (305 mm) leadlength) or crimped on leads. Longer lead lengths areavailable, but require an external connection. Thelength of a FIREROD available for centerless grindingdepends on the construction. Please contact your<strong>Watlow</strong> representative for assistance. To order, specifycenterless grinding.FIRERODActualDiameterPrecision Diameterin.in.1 /4 0.241 ± 0.00053 /8 0.363 ± 0.00051 /2 0.488 ± 0.00055 /8 0.613 ± 0.00053 /4 0.738 ± 0.00051 1 0.984 ± 0.00051 A minimum charge per line item applies.Bolt <strong>Heater</strong>sThe high performance FIREROD can be upgraded with aconduit box and wooden handle.When inserted into a hollow bolt, this heater lengthensthe bolt by heat expansion allowing the nut to be furtherwrench-tightened. The FIREROD bolt is then de-energizedand removed. Upon cooling, the bolt contracts to atight fit.Performance Capabilities• Part temperatures up to 1000°F (540°C)• Maximum watt density up to 100 W/in 2 (15.5 W/cm 2 )5 in. (127 mm)No-HeatWooden HandleNickel-ChromiumResistance Wire4 in. (101 mm) Conduit Boxwith Post Terminals1 in. (25 mm) No-HeatMagnesiumOxide InsulationAlloy 800SheathDiameter ±0.005 in.Maximum VoltsMaximum Amperes120 Maximum Watts240 Maximum Watts1 PH 4803 PH AvailableFIREROD Bolt Specifications0.4962409.71,1602,320——0.621480232,7605,52011,000—Note: Minimum charge per line item applies.0.746480465,52011,00022,000YES0.996480465,52011,00022,000YES32 WATLOW ®

Cartridge/Insertion <strong>Heater</strong>sFIREROD Cartridge <strong>Heater</strong>sMade-to-OrderMounting OptionsThreaded FittingsFlangesLead End Flush WithHex Standard Location1⁄16 in. (1.6 mm)(nominal)0.250 in.Min. No-HeatOptional Location¼ in. (6 mm)Standard LocationOptional FittingLocationOptional FittingLocationCDThreaded fittings allow fast, water-tight heater installationinto a threaded hole. Standard fittings are 304 stainlesssteel and welded to the heater sheath. Other materialsare available upon request. Double threaded fittings arealso available.Unless specified, the fitting hex is located flush with thelead end.Threaded Fittings Specifications<strong>Heater</strong>Diameterin.Pipe ThreadSize (NPTF)in. (mm)Single ThreadFitting Lengthin. (mm)Double ThreadFitting Lengthin. (mm)1 /4 1 /8 (3) 1 /2 (13) 7 /8 (22)3 /8 1 /4 (6) 5 /8 (16) 1 5 /16 (49)1 /2 3 /8 (10) 3 /4 (19) 1 3 /8 (35)5 /81 /2 (13) 7 /8 (22) 1 13 /16 (46)3 /43 /4 (19) 1 (25) 1 13 /16 (46)1 1 (25) 1 (25) 1 1 /2 (38)0.140" (3.6 mm)Locating Rings0.140 in. (3.6 mm)HStainless steel flanges are a convenient mountingmethod and can be used to position a heater withinan application. The standard location is 1 /4 in. (6 mm)from the lead end. However, a specific location maybe requested in any location along the no-heat section.Unless specified, flanges are staked to the sheath.To order, specify flange size and location.Flange SpecificationsFIRERODDiameterin.FlangeSizeDin. (mm)Cin. (mm)Hin.1 /8, 1 /4, 3 /8, 1 /2 FS 1 (25) 3 /4 (19) 0.1441 /4, 3 /8, 1 /2,/8, 3 /4FM 1 1 /2 (38) 1 1 /8 (28) 0.1565 /8, 3 /4, 1 FL 2 (51) 1 1 /2 (38) 0.201A stainless steel locating ring can be used as a retainingcollar to position a FIREROD heater if mountingrequirements are not critical. Standard locating rings arestaked to the heater sheath.To order, specify locating ring and location.Locating Ring SpecificationsOptional LocationFlush With Lead EndStandard LocationDiameter - in. 1 /43 /8 1 /2 5 /8 3 /4Ring O.D.in. (mm) 1 /2 (13) 5 /8 (16) 3 /4 (19) 7 /8 (22) 1 (25)WATLOW ®33

Cartridge/Insertion <strong>Heater</strong>sExtendedCapabilityExtended Capabilities ForCustom Cartridge <strong>Heater</strong>sSpecial cartridge heaters can be engineered and designedto meet the most difficult applications and the highestquality standards. From nuclear power plants to openheart surgeries, <strong>Watlow</strong> cartridge heaters with extendedcapabilities are exceeding customer expectations. Formore than 80 years, emphasis on sound engineering andquality control has established <strong>Watlow</strong> as a preferredsupplier for many high-performance heating requirements.For large opportunities, a solution for you can beengineered to accommodate:• Custom diameters• High watt density applications• Long heater lengths• Low current leakage constructions• Special testing and inspection• Non-destructive testing: x-ray, helium leak tests andstart up verification• Integrated thermostats• Value added integration of the <strong>Watlow</strong> heater into asub-assembly• Complete documentation packages: approvaldrawings, material traceability, inspection traceabilityand other compliance documents.10 ft(3 m)High Performance Cartridge <strong>Heater</strong>s<strong>Watlow</strong> has developed a wide range of heaters and assembliesto meet requirements for the most demanding applications.<strong>Watlow</strong> can engineer and manufacture heaters with low leakageconstructions, integrated temperature controls or limits andunique customer hardware and connectors.Nuclear Pressurizer <strong>Heater</strong>s<strong>Watlow</strong> has provided specialized heaters to the nuclear industryfor more than 40 years. <strong>Watlow</strong> pressurizer heaters are highlyreliable and manufactured to meet the exacting standards of thenuclear industry.34 WATLOW ®

Cartridge/Insertion <strong>Heater</strong>sExtended Capabilities ForFIREROD Cartridge <strong>Heater</strong>sMade-to-OrderTermination OptionsLow Electrical LeakageThis construction technique minimizes current leakageof the heating element. It is especially useful in criticalmedical applications where low set point ground faultinterrupts are used.Low electrical leakage is available on 3 /8, 1 /2, 5 /8 and3 /4 in. (10, 13, 16 and 19 mm) diameter FIRERODheaters.To order, specify low electrical leakage.SJO CordMin. No-Heat1 1 /4 in.(32 mm)SJO cord is used in low temperature applications wherelead wires require protection against moisture or whenUL ® listed plugs are needed. This cord is limited to140°F (60°C) under continuous operation.FIREROD heaters greater than 10 in. (250 mm) have aminimum no-heat section of approximately 12 percent+ 1 /4 in. (6 mm) of the overall length.To order, specify either two conductor or threeconductor as well as overall length.Terminal BoxOptionsBent FIREROD1 /4 in.(6 mm)HeatedBend Radius1 /4 in.(6 mm)1 in.min.(25 mm)UnheatedExtendedCapabilityIn applications where leads must exit at an angle,a bend can be made in the unheated section only.Heated sections may be on either side of the bend.It is recommended that the heater be bent at the<strong>Watlow</strong> factory.A 304 stainless steel sheath is used on bent FIRERODheaters. If the sheath temperature exceeds 1000°F(540°C), contact your <strong>Watlow</strong> representative.See dimensions noted on the chart or contact your<strong>Watlow</strong> representative if application needs exceedlimitations shown.FIREROD Min. Required BendDiameter No-Heat Length Radiusin. in. (mm) in. (mm)1 /4 2 1 /4 (56) 1 /2 (13)3 /8 2 3 /8 (60) 1 /2 (13)1 /2 2 7 /8 (72) 3 /4 (19)5 /8 3 5 /16 (83) 1 (25)3 /4 3 13 /16 (98) 1 1 /4 (32)4 in.(100 mm)Mounting OptionsLA Brass Threaded Fittings1 1 /2 in.(38 mm)1The no-heatsection is thesame as unitswith threadedfittings.1*A 4 in. (100 mm) NEMA 1 octagonal terminal box ismounted on a flange or a threaded fitting. Boxes have1 /2 in. (13 mm) conduit knockouts for electrical connection.Hazardous location (NEMA 4 and NEMA 7) terminal boxesare also available. Contact your <strong>Watlow</strong> representative fordetails. Terminal boxes are available on 1 /2 in. (13 mm)through 1 in. (25 mm) diameter FIREROD heaters.To order, specify terminal box and NEMA type.WATLOW ®Standard Fitting LocationOptional Fitting LocationFitting overlaps the unheated section and is silver soldered tothe sheath.Threaded fittings allow fast, water-tight installation of theheater into a threaded hole. These fittings are brass, otheralloys are available upon request. Double threaded fittingsare also available.Minimum UnheatedPlease see page 33 for threaded fitting specifications.Provide the location of the fittings if no-heat extensionoption is requested. Specify the location for option B.AB35

Cartridge/Insertion <strong>Heater</strong>sExtended Capabilities ForHigh-Temperature (HT) FIREROD ®<strong>Heater</strong>sThe <strong>Watlow</strong> HT FIREROD heater is especially designedfor high temperature platen applications up to 1600°F(871°C). The HT FIREROD heater utilizes the sameindustry leading design principles used on all <strong>Watlow</strong>FIREROD products. Advancing the FIREROD heaterenables it to withstand application temperatures up to400°F (204°C) higher than standard cartridge heaters.HT FIREROD design features, which are important in hightemperature applications, include:• A specially constructed end seal that is virtually airtightto reduce the effects of resistance wire oxidation• A high-temperature sheath that is treated to improveits emissivity for better heat transferPerformance Capabilities• Platen temperatures up to 1600°F (871°C)• Maximum watt density up to 100 W/in 2 (15.5 W/cm 2 )• Maximum voltage up to 277VAC ground• Length tolerance of +0, -4 percent standard diameters;+0, -8 percent for special diameterMade-to-Order AvailabilityNominalActualDiameter Diameter Max.in. in. Amperes1 /2 0.496 ± 0.004 105 /8 0.580 ± 0.004 230.621 ± 0.004 233 /4 0.710 ± 0.004 460.746 ± 0.004 461 0.960 ± 0.004 460.996 ± 0.006 46Contact your <strong>Watlow</strong> representative for special diameter requests.Features and BenefitsHigh-temperature seal• Reduces exposure to the atmosphere, whichminimizes oxidation of the winding wires resulting inlonger element lifeNote: The first 2 in. (51 mm) must be outside of theplaten in free air and less than 1000°F (538°C).Alloy 800 sheath• Transfers heat more efficientlyHigh emissivity sheath• Provides better heat transfer and longer lifeFiberglass InsulatedCrimped-on LeadsInsulationBootsOptionalCeramicBeadsHighTemperatureSeal*ConductorPinsNickel-chromiumResistance Wire* First 2 in. (51 mm) at lead end must be kept below 1000°F (538°C).Typical Applications• Thermo plastic• Super plastic forming of titanium aircraft parts• Diffusion bonding to laminate and shape titaniumExtendedCapabilityMgO InsulationAlloy 800 Sheath3 in. (76 mm)Min. No-Heat Section36 WATLOW ®

Cartridge/Insertion <strong>Heater</strong>sExtendedCapabilityExtended Capabilities ForHigh-Temperature (HT) FIREROD<strong>Heater</strong>sApplications and Technical DataOptions• Thermocouples• Independently controllable heat zones• Distributed wattage0.1000.0900.0800.070Maximum Allowable Watt Density -Heating Metals• Flanges0.060• Post terminals• Conduit NEMA boxes0.050• Bent FIREROD0.040To consider the HT FIREROD for your application, usethe recommended Maximum Watt Density graph shown.Fit in Hole (in.)0.0300.0201600°F1500°F1400°F1200°F1300°F0.0100.0090.0080.0070.0060.00530 40 50 60 70 80 90 100Watt Density—W/in 2WATLOW ®37

Cartridge/Insertion <strong>Heater</strong>sFIREROD Cartridge <strong>Heater</strong>s<strong>Heater</strong> Part NumbersDiameterin.Sheath Lengthin. (mm) Volts WattsWatt DensityW/in 2 (W/cm 2 )Approx. Net Wt.lbs (kg) Part Number1 /8 1 (25.0) 24 20 104 (16) 0.02 (0.009) C1A-9600 11 (25.0) 24 25 130 (20) 0.02 (0.009) C1A-9601 11 (25.0) 24 30 157 (24) 0.02 (0.009) C1A-9602 11 (25.0) 48 20 104 (16) 0.02 (0.009) C1A-9603 11 (25.0) 48 40 208 (32) 0.02 (0.009) C1A-9604 11 (25.0) 50 50 260 (40) 0.02 (0.009) C1A-9605 11 1 /4 (32.0) 120 25 87 (13) 0.02 (0.009) C1E141 1 /4 (32.0) 120 50 174 (18) 0.02 (0.009) C1E131 1 /4 (32.0) 240 35 113 (27) 0.02 (0.009) C1E421 1 /2 (38.0) 120 30 78 (12) 0.02 (0.009) C1J51 1 /2 (38.0) 120 60 156 (24) 0.02 (0.009) C1J62 (51.0) 120 50 87 (13) 0.02 (0.009) C2A42 (51.0) 120 100 174 (27) 0.02 (0.009) C2A51 /4 1 (25.0) 120 80 208 (32) 0.02 (0.009) E1A511 (25.0) 120 100 260 (40) 0.02 (0.009) E1A521 (25.0) 120 150 390 (60) 0.02 (0.009) E1A531 (25.0) 240 100 250 (39) 0.02 (0.009) E1A661 1 /4 (32.0) 120 75 130 (20) 0.02 (0.009) E1E411 1 /4 (32.0) 120 100 173 (27) 0.02 (0.009) E1E421 1 /4 (32.0) 120 150 260 (40) 0.02 (0.009) E1E431 1 /4 (32.0) 240 225 390 (60) 0.02 (0.009) E1E611 1 /2 (38.0) 120 50 65 (10) 0.02 (0.009) E1J391 1 /2 (38.0) 120 100 130 (20) 0.02 (0.009) E1J401 1 /2 (38.0) 120 150 195 (30) 0.02 (0.009) E1J411 1 /2 (38.0) 240 175 228 (35) 0.02 (0.009) E1J491 1 /2 (38.0) 120 200 260 (40) 0.02 (0.009) E1J421 1 /2 (38.0) 240 200 260 (40) 0.02 (0.009) E1J521 1 /2 (38.0) 240 250 325 (50) 0.02 (0.009) E1J352 (51.0) 120 80 68 (11) 0.03 (0.014) E2A1362 (51.0) 120 100 87 (13) 0.03 (0.014) E2A552 (51.0) 240 125 108 (17) 0.03 (0.014) E2A822 (51.0) 120 150 130 (20) 0.03 (0.014) E2A562 (51.0) 240 150 130 (20) 0.03 (0.014) E2A772 (51.0) 120 200 173 (27) 0.03 (0.014) E2A572 (51.0) 240 200 173 (27) 0.03 (0.014) E2A502 (51.0) 120 250 217 (33) 0.03 (0.014) E2A722 (51.0) 240 250 215 (33) 0.03 (0.014) E2A762 (51.0) 240 300 260 (40) 0.03 (0.014) E2A832 1 /2 (64.0) 120 250 159 (25) 0.03 (0.014) E2J802 1 /2 (64.0) 240 250 159 (25) 0.03 (0.014) E2J493 (76.0) 120 100 52 (8) 0.04 (0.018) E3A483 (76.0) 120 200 104 (16) 0.04 (0.018) E3A493 (76.0) 240 200 104 (16) 0.04 (0.018) E3A603 (76.0) 240 250 128 (20) 0.04 (0.018) E3A1243 (76.0) 120 300 156 (24) 0.04 (0.018) E3A503 (76.0) 240 300 156 (24) 0.04 (0.018) E3A514 (102.0) 120 100 37 (6) 0.04 (0.018) E4A284 (102.0) 120 200 74 (11) 0.04 (0.018) E4A294 (102.0) 240 200 74 (11) 0.04 (0.018) E4A324 (102.0) 120 300 111 (17) 0.04 (0.018) E4A304 (102.0) 240 300 111 (17) 0.04 (0.018) E4A6RAPID SHIP heaters are manufactured to standard specifications. 12 inch crimped on GGS Ieadssupplied unless otherwise specified.1 12 inch GGS swaged-in leads, no additional options available.RAPID SHIP• Next day shipmentCONTINUED38 WATLOW ®

Cartridge/Insertion <strong>Heater</strong>sFIREROD Cartridge <strong>Heater</strong>s<strong>Heater</strong> Part NumbersDiameterin.Sheath Lengthin. (mm) Volts WattsWatt DensityW/in 2 (W/cm 2 )Approx. Net Wt.lbs (kg) Part Number1 /4 4 1 /2 (114.0) 120 200 64 (10) 0.05 (0.023) E4J305 (127.0) 240 350 101 (16) 0.05 (0.023) E5A455 (127.0) 120 400 113 (18) 0.05 (0.023) E5A575 (127.0) 240 400 113 (18) 0.05 (0.023) E5A346 (152.0) 240 400 94 (14) 0.06 (0.027) E6A468 (203.0) 240 800 136 (21) 0.08 (0.036) E8A763 /8 1 (25.0) 120 55 95 (15) 0.03 (0.014) G1A711 (25.0) 120 100 172 (26) 0.03 (0.014) G1A291 (25.0) 120 150 259 (40) 0.03 (0.014) G1A381 (25.0) 240 200 344 (53) 0.03 (0.014) G1A831 1 /4 (32.0) 120 100 115 (18) 0.03 (0.014) G1E911 1 /4 (32.0) 120 125 144 (22) 0.03 (0.014) G1E741 1 /4 (32.0) 120 150 172 (27) 0.03 (0.014) G1E921 1 /4 (32.0) 240 150 172 (27) 0.03 (0.014) G1E931 1 /4 (32.0) 120 200 230 (35) 0.03 (0.014) G1E941 1 /4 (32.0) 240 200 230 (35) 0.03 (0.014) G1E951 1 /4 (32.0) 120 400 426 (66) 0.03 (0.014) G1E991 1 /2 (38.0) 120 50 43 (7) 0.04 (0.018) G1J251 1 /2 (38.0) 120 75 65 (10) 0.04 (0.018) G1J701 1 /2 (38.0) 120 80 68 (11) 0.04 (0.018) G1J661 1 /2 (38.0) 120 100 86 (13) 0.04 (0.018) G1J591 1 /2 (38.0) 240 100 86 (13) 0.04 (0.018) G1J1101 1 /2 (38.0) 240 125 106 (16) 0.04 (0.018) G1J1821 1 /2 (38.0) 120 150 129 (20) 0.04 (0.018) G1J311 1 /2 (38.0) 240 150 129 (20) 0.04 (0.018) G1J391 1 /2 (38.0) 120 200 173 (27) 0.04 (0.018) G1J851 1 /2 (38.0) 240 200 173 (27) 0.04 (0.018) G1J731 1 /2 (38.0) 120 250 216 (33) 0.04 (0.018) G1J861 1 /2 (38.0) 240 250 216 (33) 0.04 (0.018) G1J541 3 /4 (45.0) 120 125 86 (13) 0.05 (0.023) G1N451 3 /4 (45.0) 120 175 122 (19) 0.05 (0.023) G1N461 3 /4 (45.0) 120 250 172 (27) 0.05 (0.023) G1N431 3 /4 (45.0) 240 250 172 (27) 0.05 (0.023) G1N322 (51.0) 120 50 29 (5) 0.06 (0.027) G2A532 (51.0) 120 75 42 (7) 0.06 (0.027) G2A1922 (51.0) 120 100 57 (9) 0.06 (0.027) G2A842 (51.0) 240 100 57 (9) 0.06 (0.027) G2A762 (51.0) 120 150 86 (13) 0.06 (0.027) G2A562 (51.0) 240 150 86 (13) 0.06 (0.027) G2A812 (51.0) 120 200 115 (18) 0.06 (0.027) G2A1272 (51.0) 240 200 115 (18) 0.06 (0.027) G2A372 (51.0) 120 250 144 (22) 0.06 (0.027) G2A472 (51.0) 240 250 144 (22) 0.06 (0.027) G2A732 (51.0) 120 300 172 (27) 0.06 (0.027) G2A1392 (51.0) 240 300 172 (27) 0.06 (0.027) G2A982 (51.0) 120 400 230 (36) 0.06 (0.027) G2A1532 (51.0) 240 400 230 (36) 0.06 (0.027) G2A1462 (51.0) 120 500 282 (44) 0.06 (0.027) G2A952 (51.0) 240 500 282 (44) 0.06 (0.027) G2A972 1 /4 (57.0) 120 75 37 (6) 0.07 (0.032) G2E882 1 /4 (57.0) 120 125 62 (10) 0.07 (0.032) G2E89RAPID SHIP heaters are manufactured to standard specifications. 12 inch crimped on GGS Ieadssupplied unless otherwise specified.RAPID SHIP• Next day shipmentCONTINUEDWATLOW ®39