CONSTRUCTION PHASE PLAN - Shepway District Council

CONSTRUCTION PHASE PLAN - Shepway District Council

CONSTRUCTION PHASE PLAN - Shepway District Council

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

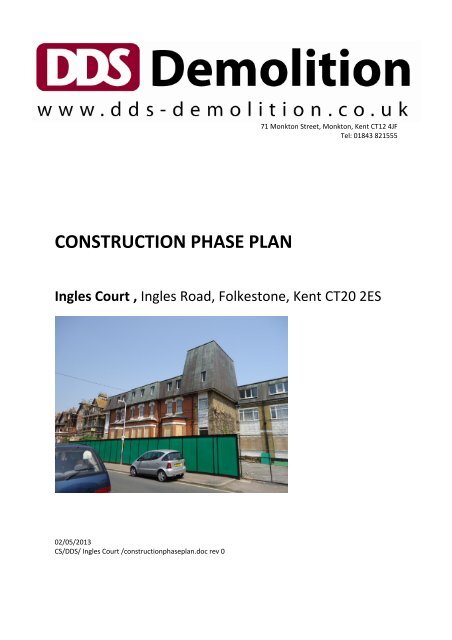

71 Monkton Street, Monkton, Kent CT12 4JFTel: 01843 821555<strong>CONSTRUCTION</strong> <strong>PHASE</strong> <strong>PLAN</strong>Ingles Court , Ingles Road, Folkestone, Kent CT20 2ES02/05/2013CS/DDS/ Ingles Court /constructionphaseplan.doc rev 0

document: CS/DDS/Ingles Court/constructionphaseplan.doc rev 0date: 10th May 2013page no: 3Contact:Tel:Fax:Mob:e-mail:Contact:Tel:Fax:Mob:e-mail:Tel:Fax:

document: CS/DDS/Ingles Court/constructionphaseplan.doc rev 0date: 10th May 2013page no: 4Contents1.0 General 71.1 Introduction 81.2 Notification F10 101.3 Project Safety Statement 112.0 Scope of Works 133.0 Executive Summary 154.0 Existing Environment 194.1 Surrounding Land Uses and Associated Considerations 204.2 Existing Buildings/Structure/Plant 224.3 Existing Services 244.4 Asbestos 264.5 Pigeon Infestation 294.6 Leptospirosis 315.0 Site Establishment 335.1 Notification 345.2 Site Access and Egress 365.3 Site Accommodation and Welfare 385.4 Site Plan 406.0 Method Statement 416.1 Works Method Statement 426.2 Addendum Method Statements 436.3 Method Statement Register 457.0 Health and Safety 467.1 Introduction 477.2 Responsibilities 507.3 Site Rules 537.4 Misconduct 567.5 Site Safety Inspection 587.6 Induction 607.7 P.P.E. Register 617.8 Risk Assessment Library 627.9 COSHH Assessment Library 637.10 Training/Plant Certificates 647.11 Permits to Work 657.12 Toolbox Talks 698.0 Emergency Procedure 718.1 Fire Services 728.2 Evacuation Plan 748.3 Medical Emergency 768.4 Bomb (Real or Hoax) 788.5 Accident Reporting and Investigation 80Page

document: CS/DDS/Ingles Court/constructionphaseplan.doc rev 0date: 10th May 2013page no: 5Contents9.0 Management 839.1 Sub-Contractor Vetting Procedure 849.2 Management Chart 859.2.1 Contact Numbers 879.2.2 Health and Safety Responsibilities 889.3 Curriculum Vitae 919.4 Communication 9210.0 Programme 9410.1 Bar Chart 9510.2 Progress 96Appendix A - Pre-Construction Information PackPage

document: CS/DDS/Ingles Court/constructionphaseplan.doc rev 0date: 10th May 2013page no: 6RevisionRevision 0 09th May 2013 - Issued for commentRevision 1Revision 2This document will be reviewed at regular intervals and revised as necessary. The details of the review will bedocumented below.Date Reviewed By Signature Comments

document: CS/DDS/Ingles Court/constructionphaseplan.doc rev 0date: 10th May 2013page no: 71.0 General

document: CS/DDS/Ingles Court/constructionphaseplan.doc rev 0date: 10th May 2013page no: 81.1 Introduction

document: CS/DDS/Ingles Court/constructionphaseplan.doc rev 0date: 10th May 2013page no: 91.1 IntroductionThe following document is applicable to all employees of DDS Demolition Ltd, Sub-contractors and their employees.The objective is to compile and assemble relevant information into one document regarding methods, proceduresand details specific to the demolition works contract of:The Former Ingles CourtIngles RoadFolkestoneKent CT20 2ESThe document will be related to all personnel involved in the project and will be updated during the contractperiod to reflect any fundamental modifications.This Construction Phase Plan will be developed prior to commencing on site to include more detail concerning sitecompound areas, demolition exclusion zones and traffic management.DDS will coordinate with operatives from other companies through:o Integration meetings with Others to cross reference the sequence of the worko Health, Safety and Environmental briefingsThe following factors need to be considered:o Access to the site and work areaso Delivery of materials and equipmento Provision of electrical power supplied by DDS generatoro Secure weatherproof site storageo Access to welfare facilities

document: CS/DDS/Ingles Court/constructionphaseplan.doc rev 0date: 10th May 2013page no: 101.2 Notification F10

document: CS/DDS/Ingles Court/constructionphaseplan.doc rev 0date: 10th May 2013page no: 142.1 Scope of WorksThe works generally comprise the strip out and demolition works to theoooooooooClient McCarthy & Stone Ltd to erect Heras/Hoarding fencing demarcate the CDM project site. DDS tocreate a demolition exclusion zones;Confirm isolation and termination of services in the building - liaise with the Client Team McCarthy &Stone ;Erect scaffolding in accordance with party wall awards.Remove asbestos containing materials;Soft strip furniture, fixtures, fittings and non-load bearing structures;Demolish structures to top of slab level;Break out slabs and hard standings;Remove all demolition, rubbish and soft strip materials arising;Leave site clean, safe and tidy on completionAs fully described in Contract Documentation.

document: CS/DDS/Ingles Court/constructionphaseplan.doc rev 0date: 10th May 2013page no: 194.0 Existing Environment

document: CS/DDS/Ingles Court/constructionphaseplan.doc rev 0date: 10th May 2013page no: 204.1 Surrounding Land Uses and Associated Considerations

document: CS/DDS/Ingles Court/constructionphaseplan.doc rev 0date: 10th May 2013page no: 214.1 Surrounding Land Uses and Associated ConsiderationsThe site is located at Ingles Road, Folkestone Kent approximately 700m to the West of Folkestone town centre.Christ Church Road and Ingles Road define the Western and Southern boundaries respectively, to the North andEast of the site are residential properties. The site comprises an L shape plot of approximately 0.17 hectares andwas a former residential care home which is three to four storeys in height.The nearest Fire Station is 0.5 miles away in located in Park Farm Road Folkestone CT19 5LT (01303 227201) thenearest Police Station is 0.2 miles away in Folkestone at Bouverie House, Bouverie Road West CT20 2SG (Tel: 101 -formerly Tel: 01303 850055).The nearest Hospital with Accident and Emergency the nearest Hospital with Accident and Emergency is 14miles away in Ashford:The Williams Harvey Hospital, Kennington Road, Willesborough, Ashford, Kent. (01233 633331).During the course of the demolition works the safety and welfare of the General Public and neighbouringoccupants is paramount. Every effort will be made to ensure disruption is minimised.

document: CS/DDS/Ingles Court/constructionphaseplan.doc rev 0date: 10th May 2013page no: 224.2 Existing Site / Buildings

document: CS/DDS/Ingles Court/constructionphaseplan.doc rev 0date: 10th May 2013page no: 234.2 Existing Site / BuildingsThe building is 3 to 4-storey and of load bearing construction with concrete slabs and brick walls. The roofis pitched with a timber frame and clad in felt.There are gardens to the front and rear of the building.

document: CS/DDS/Ingles Court/constructionphaseplan.doc rev 0date: 10th May 2013page no: 244.3 Existing Services

document: CS/DDS/Ingles Court/constructionphaseplan.doc rev 0date: 10th May 2013page no: 254.3 Existing ServicesThe arrangements for termination / diversion of services are to be carried out by Client Team McCarthy & Stone Ltd– Certificates confirming termination are to be issued by the Client Team. Any live services are to be clearly markedand identified during site induction.The termination / diversion will be confirmed prior to commencing the demolition of the building and the removalof any pipework.Protection will be placed over locations of lives services in the ground at plant crossover points in areas adjacent tothe demolition.DDS will make checks to taps, switches and sockets to confirm the termination of services into the buildings.Owing to the nature and history of the site other non-previously recorded services and alike may exist.Vigilance will be maintained during the works to ensure that should further services be discovered not previouslyrecorded, damage is nor caused to person or property.Any such discovery will be immediately reported to the Client Team.CAT detectors will be utilised and all cables traced and identified prior to breaking out ground bearing slabs etc.

document: CS/DDS/Ingles Court/constructionphaseplan.doc rev 0date: 10th May 2013page no: 264.4 Asbestos

document: CS/DDS/Ingles Court/constructionphaseplan.doc rev 0date: 10th May 2013page no: 274.4 AsbestosRefurbishment and Demolition asbestos surveys have been carried out by Astra Uk Contracts and asbestosmaterials have been identified.Licensed WorkIn accordance with The Control of Asbestos Regulations 2012 any Licensed Works will be carried out by a SpecialistContractor.A 14 day notification (ASB5) will be required to be submitted to the HSE prior to these works commencing.The asbestos removal works will be coordinated with the strip out and demolition. A copy of the waste disposalnote and air clearance certificate will be issued for the Health & Safety File.The Method Statement will cover, but not limited to, the following: -oooooooAccess and egress requirements, transit / waste routes etc.Details of respiratory apparatus and clothing to be used to protect the operatives.Methods for the safe handling of asbestos waste.Type and location of decontamination facilities and transit procedures.Details of the type, extent and position of all enclosures, including airlock systems if required by thechosen asbestos removal method.Procedures for the safe containment, transport and ultimate disposal of asbestos waste.Separate Risk Assessments will be attached to Specialist Contractors Method Statement.There may be locations where a partial soft strip will be necessary in order to provide access to remove theasbestos.Non-Licensed WorkThe more friable a material is, the more likely it will release asbestos fibres when worked on and the greater therisk of exposure. Work which disturbs more friable materials e.g. asbestos insulation will tend to be Notifiable Non-Licensed Work (NNLW) and will require notification to the HSE. Work which disturbs the least friable materials e.g.asbestos cement can normally be treated as Non-Licensed Work (NLW) and does not need to be notified to theHSE.Asbestos containing materials (ACMs) where the asbestos is coated, covered or contained within another material,such as cement, paint or plastic are considered to be firmly bonded in a matrix, ACMs of this type in good conditioncan usually be treated as NLW but where they are significantly damaged, and so more likely to release fibres, theywill need to be treated as NNLW.The material's condition:• Has the material been damaged or is it in poor condition? – removal of ACMs in poor condition e.g. due toflood or fire damage, will normally need to be treated as NNLW; and• Will the materials' matrix be destroyed when worked on? – e.g. deteriorating textured decorative coatingse.g. 'Artex' with gel or steam to remove it, will normally need to treated as NNLW.

document: CS/DDS/Ingles Court/constructionphaseplan.doc rev 0date: 10th May 2013page no: 284.4 Asbestos (continued)NNLW materials will be notified to the HSE however these materials can be removed by a non-licensed contractorhowever the materials must be taken by a licensed carrier to a licensed tip.NLW materials will not be notified to the HSE and these materials can be removed by a non-licensed contractor.Similarly the materials must be taken by a licensed carrier to a licensed tip.DDS’s operatives have attended UKATA Asbestos Operatives Three Day Training Course and the management teamhave attended a UKATA Three Day Asbestos Supervisors course.During the removal operation the following precautions will be taken to ensure that the operatives are not exposedto fibre concentrations above the Control Limits.oooooAt the site induction, the operatives who will be involved in the removal works will undertake a thoroughinduction explaining the respective hazards and control measures, method statement and emergencyprocedures.All operatives will be issued with FFP3 ori-nasal dust masks or Sundstrom oral / nasal half masks,instructed regarding their correct fitting, cleaning and storage.Strict hygiene procedures must be maintained - No smoking, drinking or eating whilst working, removeoveralls and wash hands, arms and face thoroughly before meal breaksAll operatives will wear Type 5 disposable overalls of a suitable type that will be regularly disposed ofwhen dirty and not washed then re-worn.Under the supervision of an analyst, background monitoring may be carried out - the number of the tests,frequency and duration will depend upon the advice from the analyst.DDS’s operatives continuously work in environments where the possibility of discovering further asbestos, notpicked up on surveys or during asbestos stripping procedures, exists. Such locations are:ooooooobeneath items of heavy plantwithin items of plantin live electrical apparatussealed in pipes and ductworkin ducts / risers inaccessible at time of surveythrough concrete slabs and beams - cast in situmaterials used as permanent shutteringIf during strip out, de-planting or demolition further asbestos based materials are discovered the GeneralForeman/Site Supervisor will be notified at once and the area will be sealed off and all works in the immediate areawill cease.

document: CS/DDS/Ingles Court/constructionphaseplan.doc rev 0date: 10th May 2013page no: 294.5 Pigeon Infestation

document: CS/DDS/Ingles Court/constructionphaseplan.doc rev 0date: 10th May 2013page no: 314.6 Leptospirosis

document: CS/DDS/Ingles Court/constructionphaseplan.doc rev 0date: 10th May 2013page no: 335.0 Site Establishment

document: CS/DDS/Ingles Court/constructionphaseplan.doc rev 0date: 10th May 2013page no: 345.1 Notification

document: CS/DDS/Ingles Court/constructionphaseplan.doc rev 0date: 10th May 2013page no: 355.1 NotificationPrior to commencing on site, the following arrangements will have been made by the Client Team: -ooooooForm F10 Notification to HSETermination / diversion of supplies into the buildings and provision of the necessary temporary suppliesAll necessary awards, boundary agreements and permissionsNotification to Local Borough <strong>Council</strong> regarding Section 80 of the Building Act 1984 regarding thecommencement of demolition worksNotification to adjacent propertiesHoarding fencingPrior to commencing works on site, the following arrangements will have been made by DDS: -oooo14 day Notification to remove asbestosNotification to local Police and Fire BrigadeEstablish welfare facilitiesDDS site induction to DDS employees and subcontractorsThe condition of adjacent buildings, existing entrance roadway, street furniture, fences and boundary wallsetc. will be agreed and confirmed with the Client Team.Prior to commencing on site a meeting was arranged, involving the relevant parties to the project, in order tofinalise project details and determine outstanding information.

document: CS/DDS/Ingles Court/constructionphaseplan.doc rev 0date: 10th May 2013page no: 375.2 Site Access and EgressDDS will maintain the existing boundary Heras/Hoarding fencing already erected by Client McCarthy & Stone Ltd.Heras/Hoarding fencing gates have been incorporated into the Heras/Hoarding fencing at the site entrance byClient McCarthy & Stone Ltd. The gates will be kept closed whenever possible to prevent unauthorised entry to thedemolition site during the working day.Signs will be erected by DDS warning of the nature of the works to be undertaken and a signboard displayed withall relevant contact names including a 24hr telephone number.The fencing/hoarding will be kept closed to prevent unauthorised entry to the site during the working shift. At theend of each shift a check will be made to the security of the site to ensure it is properly secured.The local roads will be used to access the working area. All vehicles travelling along the local roads will obey thelocal speed limits.A banksman (wearing hi-vis) will be posted at the site entrance whilst marshalling wagons or delivery vehicleson/off the site. The gateman will liaise with all delivery drivers and ensure records (waste tickets etc) are in place.All deliveries to and from site, in particular H.G.V's, will be carefully coordinated to ensure minimal disruption tothe local environment is caused.Site and road conditions will be continuously monitored and adequate facilities will be provided for wheel washingand road cleaning should it be necessary.

document: CS/DDS/Ingles Court/constructionphaseplan.doc rev 0date: 10th May 2013page no: 385.3 Site Accommodation and Welfare

document: CS/DDS/Ingles Court/constructionphaseplan.doc rev 0date: 10th May 2013page no: 395.3 Site Accommodation and WelfareWelfare facilities, to comply with the requirements of Schedule 2 of CDM Regulations 2007, will be established byDDS in mobile self-contained units. These facilities will be located in site boundary in Manley Close.Electrical power will be obtained from a generator. Water will be obtained from a temporary supply.The access route from the site entrance will be clearly defined with signs and arrows.The scope and extent of these facilities will compliment the demolition being undertaken, the duration, thenumber of employees and sub-contractors on site, the weather conditions expected during the contract and thelocation of the site with respect to the facilities already present in the area.Consideration has been given to the provision of the following: -a) toilets : Yesb) washing facilities : Yesc) drying room for wet clothing : Yesd) changing facilities : Yese) messing facilities : Yesf) canteen : Yesg) first aid room : Site OfficeNumber of people Number of toilets Number of Urinals1 – 15 1 116 – 30 2 131 – 45 2 246 – 60 3 2

document: CS/DDS/Ingles Court/constructionphaseplan.doc rev 0date: 10th May 2013page no: 405.4 Site Plan

document: CS/DDS/Ingles Court/constructionphaseplan.doc rev 0date: 10th May 2013page no: 416.0 Method Statement

document: CS/DDS/Ingles Court/constructionphaseplan.doc rev 0date: 10th May 2013page no: 426.1 Works Method Statement

71 Monkton Street, Monkton, Kent CT12 4JFTel: 01843 821555Ingles CourtIngles Road , Folkestone, Kent CT20 2ESDEMOLITION METHOD STATEMENT12 th may 2013kpml/dds/Ingles Court/methodstatement.doc rev 0

document: kpml/dds/inglescourt/methodstatement.doc rev 0date: 12 may 2013page no: 2Section Contents Page1.02.03.04.05.06.07.08.09.010.011.012.0IntroductionScope of WorksSite Establishment (prior to commencement)Site Establishment (on site)Asbestos RemovalScaffold ErectionSoft StripStructural DemolitionCOSHH Assessment LibraryRisk Assessment LibraryHealth and Safety NotesConclusion36781618192124252628Appendix ASite Induction ProformaSite Induction RegisterPersonal Protective Equipment RegisterMethod Statement RegisterMethod Statement AddendumPrepared By: P Seymour Authorised By: J PreeceSigned:P SeymourDated: 12 th May 2013Signed:Dated:

document: kpml/dds/inglescourt/methodstatement.doc rev 0date: 12 may 2013page no: 31.0 IntroductionWith this Method Statement, DDS Demolition Ltd will illustrate how the demolition of Ingles Court, InglesRoad, Folkestone, Kent CT20 2ES will be carried out for McCarthy & Stone (Client).DDS will be Principal Contactor for the duration of the demolition stage of the Contract – To be Confirmed.The site contains structures of differing construction.At the northern end the building is 3-story and of load bearing brick construction with timber floors and atimber framed mansard roof structure.The southern end is of more recent construction and comprises a 3-storey reinforced concrete frame, rc floorsand external brick cladding.A basement partially extends beneath the footprint of the building.DDS are 9001, 14001 & 18001 compliant and proud of our respected reputation within the ConstructionIndustry for the successful completion of sensitive demolition contracts.DDS have good local knowledge having previously carried out successful demolition projects in Folkestone andthe surrounding areas.All demolition works will be carried out in accordance with BS 6187:2011 - Code of Practice for Demolition.

document: kpml/dds/inglescourt/methodstatement.doc rev 0date: 12 may 2013page no: 41.0 Introduction (continued)DDS are fully aware that the key to a successful contract will be to fully segregate and protect the GeneralPublic and adjacent properties from the impact of the demolition works – both visually and physically, fromdebris, dust, noise & vibration.A hoarding has already been erected around the site, by McCarthy & Stone, to prevent access and create ademolition exclusion zone. Dust will be controlled with a fine water spray and where possible the demolitionwill be carried out a 360° excavator fitted with a combination of multi-purpose processor and selector grabattachments.Access to the adjacent buildings and premises will be maintained at all times – Marshalls will be positioned onthe pavement when demolishing structures adjacent to the site boundary.The demolition will be progressed gradually and will always be governed by safety. The method, routes ofaccess and techniques may change as the condition of the structures unfolds.A Refurbishment & Demolition Asbestos Survey Report Ref: AS/03112-RDS/JO dated 09/05/2013 was carriedout by Astra UK Ltd. Asbestos materials were identified. This report however did not access all areas andtherefore is incomplete. A further intrusive survey will be required.The services to the site were live. McCarty & Stone have terminated the electrical supply who will issuecertification accordingly. DDS will isolate the water supply prior to soft strip / demolition commencinghowever a temporary supply will be maintained for dust suppression.The site is located in the centre of Folkestone near to the railway station, coastline and harbour. The area ispredominantly residential.The nearest Fire Station is Folkestone Fire Station, 0.5 miles away in Park Farm Road CT19 5LT (Tel: 01303227201) and the nearest Kent County Constabulary is 0.2 miles away in Folkestone at Bouverie House,Bouverie Road West CT20 2SG (Tel: 101 - formerly Tel: 01303 850055).The nearest Hospital with Accident and Emergency is 14 miles away in Ashford:Ashford William Harvey HospitalCountry: EnglandAddress:Kennington Road, WillesboroughAshford, Kent01233 633331This hospital has an Accident and Emergency departmentContact:Telephone: 01233 633331Call NHS 111 if you urgently need medical help or advicebut it's not a life-threatening situation.Maintaining a Safety First AttitudeHealth and Safety is an integral aspect of our business and it is essential that everyone remains vigilant at alltime. Site operations by their very nature are hazardous and this is particularly the case when asbestosremoval and demolition are involved.The site will be managed by a full time, non-working, Site Supervisor.

document: kpml/dds/inglescourt/methodstatement.doc rev 0date: 12 may 2013page no: 51.0 Introduction (continued)Asbestos removal requires thorough planning, construction of airtight enclosures and meticulous procedureswhilst stripping asbestos materials to ensure fibres are not released into the atmosphere causing localisedcontamination.Demolition is dynamic with changes on site occurring very quickly. Everyone must be aware of the need toobserve safe working practices and implement all the controls that have been identified in the appropriateMethod Statements and Risk Assessments.DDS employees or subcontractors are not expected to work unsafely nor are they expected to work in unsafeenvironments. Everyone also has a legal and moral duty to report unsafe conditions and when applicable stopwork. If possible employees are asked to contribute to the identification of methods and means of achievingcontinuous improvement.The wearing of the correct PPE is of prime importance. Operatives will wear:• Hi-vis jacket / vest• Eye protection - BS EN 166B Grade 1 impact;• Protective gloves - BS EN 374;• Helmet – BS EN 397; Black (Supervisor), Red (Operative), Blue (Visitor)• Safety Boots – BS EN 345;• Dust Mask - BS EN 143;• Burning eye goggles/visor to BS EN 169;• Veraflo TR300 – Powered Air Respirator BS EN 12941; and• Ear defenders - BS EN 352 (when required).All personnel working on DDS sites are expected to follow the following basic rules:• If it is not safe do not do it; do not let your workmates do it.• If you see something that is unsafe, report it to your supervisor immediately, don’t walk by.• If you are unsure about something or do not understand the task, speak up and ask.

document: kpml/dds/inglescourt/methodstatement.doc rev 0date: 12 may 2013page no: 62.0 Scope of WorksThe works generally comprise the asbestos removal, strip out and demolition works of the existing buildings:oconfirm isolation and termination of services to the structures – Liaise with McCarthy & Stone;o remove asbestos materials –as detailed on Astra UK Ltd Ref: AS/03112-RDS/JO dated 09/05/2013;ooooooooerect scaffolding to external elevations where detailed in Party Wall agreements;soft strip services, fixtures, fittings and non-load bearing structures;demolish buildings down to u/s slab level depth 0.2m;breakout basement and basement slab;breakout foundations depth 1.0m;breakout hardstandings depth 0.2m;backfill basement with selected demolition arisings; andremove all demolition arisings, rubbish and soft strip materials arising.NB: No allowance has been made for removal of contaminated ground.

document: kpml/dds/inglescourt/methodstatement.doc rev 0date: 12 may 2013page no: 73.0 Site Establishment (prior to commencement)The CDM Coordinator will make the following arrangement: -oF10 form under C.D.M. requirementsPrior to commencing on site, the following arrangement will have been made by McCarthy & Stone: -oooNotification to Local Borough <strong>Council</strong> regarding Section 80 of the Building Act 1984 regarding thecommencement of demolition works;Termination of electrical services into the site and provision of the necessary temporary supplies; andErect hoardings to enclose the site.Prior to commencing on site, the following arrangements will have been made by DDS: -oooNotification to local Police and Fire Brigade;Erect demolition exclusion zones – Heras fencing; andEstablish site compound and welfare facilities.All necessary Planning Consents, awards, party wall / boundary agreements and permissions will be arrangedby McCarthy & Stone and in place before commencing works on site.The condition of existing road surfaces, street furniture and pavements will be agreed and confirmed withMcCarthy & Stone.DDS will carry out a photographic condition survey of the site.Prior to commencing on site a meeting will be arranged, involving the relevant parties to the project, in orderto finalise project details and confirm access & egress routes, drop zones and site welfare areas.

document: kpml/dds/inglescourt/methodstatement.doc rev 0date: 12 may 2013page no: 84.0 Site Establishment (on site)Site ManagementDue to the nature of demolition all works will be carried out with extreme caution. Vigilance regarding thestructural integrity of the buildings will be maintained at all times by operatives and Site Supervisor.It is imperative that all instructions are clearly communicated and understood. By the very nature of the worksmethods, direction of progress, access routes etc will vary from day to day, hour by hour.The DDS Site Supervisor will provide all verbal instructions to DDS operatives. There will be a senior DDSManager present on site for the duration of the works.If McCarthy & Stone / Design Team Staff have any requirements for access to the demolition site with regardinspection these requirements must be directed through the DDS Site Supervisor.The DDS Site Supervisor will ensure that the necessary arrangements to allow access, and the subsequentimplications, are thoroughly considered.All visitors to site will be escorted by DDS Site personnel.InductionPrior to commencing on site all DDS site operatives and subcontractors who will be involved with the projectwill attend a DDS Project Specific Induction course. Part of the induction process will be to ensure that theoperatives are aware of the proximity of the adjacent buildings, the method statement with the associatedRisk and COSHH assessments of their task, proximity of pedestrians and vehicles, location of any hazardousmaterials, location of live services, emergency procedures, location of fire points and 'no-go' areas ie. DropZones etc.Site working hours will be:08.00 – 18.00h Monday to Friday08.00 – 14.00h SaturdayToolbox talks will be given to operatives weekly by the Site Manager.Preparation1. Select a talk that is relevant to current operations.2. Read through the talk and decide on which points are relevant to your workforce.3. Are there any aids you can use to demonstrate your talk e.g. use of disc cutters - have one available.4. Check the area is safe - e.g. not in a congested work area.5. Keep distractions to a minimum.Task LightingThe works will generally be carried out during daylight hours however, if conditions dictate, task lighting willbe established to illuminate working areas. Emergency escape routes will be illuminated accordingly.

document: kpml/dds/inglescourt/methodstatement.doc rev 0date: 12 may 2013page no: 94.0 Site Establishment (on site) (continued)Site Emergency ProceduresIn the case of an emergency the following procedure shall be employed:The person who discovers the emergency shall call 999.Inform which emergency services are required.Wait until the location has been confirmed before ending the call.DDS staff shall direct the emergency service to the scene of the incident. DDS will send a Banksman to assistwith directing any emergency vehicles.DDS will provide trained first aiders with a first aid kit located in the site office.McCarthy & Stone will be notified as soon as possible after the incident.It is a requirement of The Reporting of Incidents, Diseases and Dangerous Occurrence Regulations 1995 (asamended 2012) that certain type of accidents, dangerous occurrences and diseases are reported to the Healthand Safety Executive. If the accident is reportable to the HSE then a member of management will fill in thedetails required on the official online form (F2508, F2508A) within the time period specified. Seven-dayaccidents will be reported to the local HSE office within fifteen days. Major injuries and dangerous occurrenceswill be reported immediately to the HSE by telephone with a report issued within fifteen days. Records of allaccidents will be kept for at least 3 years.All Lost Time Accidents (LTAs) and Riddor will be reported to McCarthy & Stone at the earliest opportunity.Traffic Management PlanThe site is located on Ingles Road and Christ Church Road near to the centre of Folkestone therefore passenger/ traffic flows will be maintained at all times. Similarly adequate safe pedestrian routes and access to adjacentproperties will be maintained.All local speed limits will be observed.A banksman (wearing hi-vis) will be posted at the site entrance whilst marshalling wagons or delivery vehicleson/off the site. There is sufficient room on site for vehicles to drive onto the site, turn, and drive of the site in aforward gear.The gateman will liaise with all delivery drivers and ensure records (waste tickets etc) are in place.The roadway adjacent to the site will be regularly swept during the course of the working day to maintaincleanliness and to minimise the mess that vehicles leaving the site can cause.All deliveries to and from site, in particular H.G.V's, will be carefully controlled to ensure minimal disruption tothe local environment is caused. All flatbed delivery vehicles will have a hand rail / edge protection system tobe used when loading / unloading.Site and road conditions will be continuously monitored and adequate facilities will be provided for wheelwashing and road cleaning should it be necessary.

document: kpml/dds/inglescourt/methodstatement.doc rev 0date: 12 may 2013page no: 104.0 Site Establishment (on site) (continued)Site BoundaryMcCarthy & Stone will have erected hoarding to demarcate the site boundary.In the location of the crossovers gates will be incorporated into the hoarding – the gates may require wideningT.B.C.The gates will be kept closed whenever possible to prevent unauthorised entry to the site during the workingshift. At the end of each shift a check will be made to the security of the site.DDS will erect Heras fencing to create exclusion zones within the site (Welfare compound).Heras fencing panels will be lifted, carried and positioned by two operatives. The feet will be lifted, carried andpositioned by one operative. The fencing panels will be double clipped. Every 5 or 6 panels the fencing will betriangulated to stabilise the fence line.Site Accommodation and WelfareWelfare facilities (Site Office, changing room, drying room, canteen, toilets, washing facilities) will beestablished by DDS and will be serviced by a temporary water supply (clearly marked). These facilities will belocated adjacent to the site entrance and fenced off to create a compound area.

document: kpml/dds/inglescourt/methodstatement.doc rev 0date: 12 may 2013page no: 114.0 Site Establishment (on site) (continued)Electrical power will be obtained from a temporary supply.The access route from the site entrance will be clearly defined.The scope and extent of these facilities will compliment the demolition being undertaken, the duration, thenumber of employees and sub-contractors on site, the weather conditions expected during the contract andthe location of the site with respect to the facilities already present in the area.Hazardous materialAsbestos – See section 5.0.The windows have been boarded up however there has been unauthorised entry into the buildings. Squattersmay have used the buildings. A thorough visual inspection will be carried out for syringes and other drugparaphernalia.During the soft strip / demolition of the buildings vigilance will be maintained to identify if any furtherhazardous materials are present.Fluorescent tubes cannot be disposed of with normal waste. They will be collected and inserted into cardboardtubes. The tubes will be taken separately to a licensed disposal facility. Similarly paint tins, fridges, televisionsand air conditioning units will be separated and disposed of accordingly.Plasterboard will be segregated and placed into separate skips.Fenced areas, to store / contain hazardous items prior to removal from site, will be designated ControlledWaste Zones.Fuel will be delivered to site and stored in a ‘Fuel Safe’ double skinned bowser and only competent personsusing serviceable equipment will undertake local refuelling of plant on site.The fuel bowser will be locked at all times when not in use. A Spill Kit will be kept on site, local to the works, incase of fuel spillage.A drip tray will be positioned beneath any items of static plant.ServicesOne of the main risks during strip out and demolition is penetrating live services. It is essential that allprecautions be taken to prevent any such occurrences.The arrangements for the termination / isolation of electrical services into the site will be made by McCarthy &Stone. Certification confirming termination / isolation will be provided accordingly.Any live services remaining will be clearly marked and identified during site induction.DDS will isolate the water supply and maintain a temporary supply for dust suppression.

document: kpml/dds/inglescourt/methodstatement.doc rev 0date: 12 may 2013page no: 124.0 Site Establishment (on site) (continued)Works will be carried out to conform to the requirements of Health & Safety Executive Guidance Note GS6‘Avoidance of Danger from Overhead Cables’, and the National Joint Utilities document ‘Recommendations onthe Avoidance of Danger from Underground Electricity Cables’.Prior to breaking out any ground bearing slab a CAT scan will be carried out to determine if there are anyunrecorded live services.A marked up drawing showing the position of any capped / terminated services will be produced by McCarthy& Stone for the Health & Safety File.Environmental ProceduresDDS aim to recycle 97% of materials arising.DDS will seek to promote the conservation and sustainable use of natural resources and to minimiseenvironmental pollution in all its own activities and, where possible, by its influence over others.DDS’s objective is to minimise the environmental impact of all our operations and to this end will review all itspolicies, services and activities and act wherever necessary, to meet this commitment.Consideration will be given to substitution of polluting substances with “greener” alternatives whereverpossible.Steps will be taken to ensure asbestos fibre release is within tolerances and smoke, dust, noise, and vibrationnuisance is minimised. The potential for which will be identified during the assessment process, which willinclude COSHH assessments.Wherever possible waste will be reused, reclaimed or recycled, however where waste has to be disposed of allwaste disposals will be transported by registered carriers and removed to registered disposal sites.Documentation will be held on site demonstrating compliance with this.Liquid pollutants will not be allowed to enter watercourses. All liquid storage will be bunded wherever there isa risk, locked when not in use and spill kits will be provided on site.Noise StrategyDDS will use all reasonably practicable means to protect the adjacent buildings from the detrimental effects ofnoise.DDS will work in accordance with the BS5228 Code of Practice which contains information and procedures forthe control of noise on construction sites.DDS will use only those items of plant producing minimum noise levels and noisy activities will be examinedwith the aim of introducing control measures, and where possible, locate plant and machinery as far as isreasonably practicable from sensitive receptors.DDS will also produce evidence of plant maintenance of all engine driven plant and vehicles. Vehicles engines,including dumpers will be switched off when the vehicle is idle or whilst being loaded. Attenuation equipmentfor tools, plant and machinery, where provided will be maintained in good condition and correctly fitted.

document: kpml/dds/inglescourt/methodstatement.doc rev 0date: 12 may 2013page no: 134.0 Site Establishment (on site) (continued)All operatives will be instructed at safety induction to ensure that noise levels are kept to a minimum and thatunnecessary shouting, abusive language or other verbal disruptions are forbidden.Dust Suppression StrategyDDS will use all reasonably practicable means to protect the adjacent buildings from the detrimental effects ofdust.The controlled use of fine water sprays will be employed to assist in the reduction of dust emissions. DDS willensure that all waste water arising is contained in such a manner that it does not give rise to flooding or createnuisance outside the working area. In addition, systems will be in place to prevent demolition debris enteringthe existing site drainage, local sewers and streams.The controlled use of fine water sprays (Hose or Jet Washer) will be used during the demolition, processingand removal of materials from site.Waste materials, including empty containers, paper, waste or debris, will be placed in designated wastedisposal skips placed around the site and not allowed to be blown about the site and adjacent area.All containers will be totally enclosed or covered by nets/tarpaulins to prevent escape of dust or wastematerials during loading and transfer from site to authorised waste recycling/disposal centres.The burning of rubbish or any other material on Site will be strictly prohibited.Hand Arm VibrationThere will be a minimal requirement to use hand held breakers during the demolition process and thereforethe exposure to Hand Arm Vibration will not be significant.Before using hand held breakers, or similar, a ‘Max Usage Period in 8 hours’ value will be calculated for eachtool.These operations will be monitored – Operatives will be rotated and will receive Health Surveillance ifconditions dictate.Safety MeetingsDDS's nominated safety advisors Prime Safety UK Ltd will visit the site at fortnightly (minimum) intervals. Asafety inspection will be carried out and resulting comments on the report implemented.Prime Safety UK Ltd will report to DDS Site Supervisor and a copy of the safety reports submitted to McCarthy& Stone).Weekly progress meetings will be held between DDS and McCarthy & Stone.

document: kpml/dds/inglescourt/methodstatement.doc rev 0date: 12 may 2013page no: 144.0 Site Establishment (on site) (continued)Drop ZoneDuring the demolition of the structure, the working face will become a Drop Zone. The Drop Zone will be thearea that demolition debris is transferred to slab level prior to loading away.The area will be clearly marked with fencing panels / bunting tape to prevent inadvertent access or will becontrolled by verbal co-ordination between the Topman / banksman and the 360° excavator driver.During the demolition of the Reading Room, Marshalls, in radio/visual contact with site personnel, will beposted on the footpath to warn of approaching pedestrians / vehicles etc.All demolition works will cease, if safe to do so, until the pedestrians / vehicles have passed by. If it is not safeto stop the demolition then the pedestrians / vehicles will be asked to wait at a safe distance until it is safe topass.Hot WorksDue to the timber present within the buildings DDS will take all reasonable steps to avoid the outbreak of fire,particularly during 'hot' work involving the use of naked flame or intense heat.A 'Hot-Works' permit to work system will be enforced when any works of this nature are undertaken and fireextinguishers will be prominent. Hot works will cease 1 hour before the end of a working shift and the areathoroughly checked by the Fire watchman prior to leaving site.It will be impressed on the workforce that the site has a ‘No Smoking’ policy and will prevent the accumulationof rubbish on the site.Oxygen and Propane bottles will be stored outside, segregated in a lockable cage in an upright position andprotected from impact – the position will be agreed on site and marked up on the site plan. Fire extinguisherswill be positioned adjacent to the storage area.The correct colour coded hoses will be used. All hoses, cutting equipment, arresters and regulators will bevisually checked prior to connection to gas bottles.All hose and terminal connections to cutting equipment and regulators / arresters will be checked for leaks.In addition to the regular PPE, during hot works operatives will wear an Airstream helmet, fire retardantoveralls, gauntlets and goggles. Consideration will be given to welding apron and boots where flame cutting isundertaken.All Terrain Telescopic HandlerWhere necessary, access to carry out the works at height will be provided from a manriding platformsupported by an all terrain telescopic handler.When in location the manriding platform will provide the edge protection local to the workface.The platform has anchor points on which to attach safety harnesses with fall restraint lanyard.

document: kpml/dds/inglescourt/methodstatement.doc rev 0date: 12 may 2013page no: 154.0 Site Establishment (on site) (continued)The operator will be certificated and experienced with works of this nature.The ground conditions will be noted to ensure the surface is level, free from debris and stable.The conditions overhead will be noted to ensure operatives on the platform are not at risk from loose debris,protrusions etc.The ‘all terrain’ telescopic handler has a Safe Working Load of 1 tonne and there is a SWL indicator in the cab.Mobile TowersWork at height may also be accessed using mobile aluminium towers. Mobile towers will be erected by PASMAcertificated persons in accordance with the manufacturer’s instructions.• The tower will be erected on a level stable surface.• The wheels will be locked to prevent movement during use.• The tower will not be repositioned whilst persons are on the working platform.• The purpose-built access ladder will be used to climb to the working platform – operatives will notclimb up the outside of the tower.• Outriggers will be used if necessary to increase the base-to-height ratio.• Equipment will be passed up to the operatives on the working platform.LeptospirosisGood personal hygiene must be maintained since there is a risk of contracting Weil’s disease if rats arepresent.The bacteria can get into your body through cuts and scratches and through the lining of the mouth, throatand eyes after contact with infected urine or contaminated water such as in sewers, ditches, ponds and slowflowing rivers. Rat urine may also contaminate animal feedstuffs on farms.The disease starts with a flu-like illness with a persistent and severe headache. Report any illness to yourdoctor – tell your doctor about your work. Leptospirosis is much less severe if it is treated promptly.If the level of rat infestation dictates a specialist contractor will be employed to fumigate / bait the affectedareas.

document: kpml/dds/inglescourt/methodstatement.doc rev 0date: 12 may 2013page no: 165.0 Asbestos RemovalA Refurbishment & Demolition Asbestos Survey Report Ref: AS/03112-RDS/JO dated 09/05/2013 was carriedout by Astra UK Ltd. Asbestos materials were identified.Both Licensed and Non-Licensed asbestos materials were identified.Licensed WorkAny Licensed Asbestos removal works will be carried out by Specialist Licensed Sub-Contractor.A 14 day notification (ASB5) will be required to be submitted to the HSE prior to these works commencing.The asbestos removal works will be coordinated with the strip out and demolition. A copy of the wastedisposal note and air clearance certificate will be issued for the Health & Safety File.The Method Statement will cover, but not limited to, the following: -oooooooAccess and egress requirements, transit / waste routes etc.Details of respiratory apparatus and clothing to be used to protect the operatives.Methods for the safe handling of asbestos waste.Type and location of decontamination facilities and transit procedures.Details of the type, extent and position of all enclosures, including airlock systems if required by thechosen asbestos removal method.Procedures for the safe containment, transport and ultimate disposal of asbestos waste.Separate Risk Assessments will be attached to Specialist Contractors Method Statement.There may be locations where a partial soft strip will be necessary in order to provide access to remove theasbestos.Non-Licensed WorkThe more friable a material is, the more likely it will release asbestos fibres when worked on and the greaterthe risk of exposure. Work which disturbs more friable materials e.g. asbestos insulation will tend to beNotifiable Non-Licensed Work (NNLW) and will require notification to the HSE. Work which disturbs the leastfriable materials e.g. asbestos cement can normally be treated as Non-Licensed Work (NLW) and does notneed to be notified to the HSE.Asbestos containing materials (ACMs) where the asbestos is coated, covered or contained within anothermaterial, such as cement, paint or plastic are considered to be firmly bonded in a matrix, ACMs of this type ingood condition can usually be treated as NLW but where they are significantly damaged, and so more likely torelease fibres, they will need to be treated as NNLW.

document: kpml/dds/inglescourt/methodstatement.doc rev 0date: 12 may 2013page no: 175.0 Asbestos Removal (continued)The material's condition:• Has the material been damaged or is it in poor condition? – removal of ACMs in poor condition e.g.due to flood or fire damage, will normally need to be treated as NNLW; and• Will the materials' matrix be destroyed when worked on? – e.g. deteriorating textured decorativecoatings e.g. 'Artex' with gel or steam to remove it, will normally need to be treated as NNLW.NNLW materials will be notified to the HSE however these materials can be removed by a non-licensedcontractor however the materials must be taken by a licensed carrier to a licensed tip.NLW materials will not be notified to the HSE and these materials can be removed by a non-licensedcontractor. Similarly the materials must be taken by a licensed carrier to a licensed tip.The ACMs are in good condition and therefore NLW.DDS will remove the NLW asbestos materials detailed on Survey Report Ref: AS/03112-RDS/JO dated09/05/2013.The asbestos materials will be damped down with water and carefully removed, keeping whole where possiblethen placed by hand into a polythene lined lockable skip. At the end of each shift the skip will be encapsulatedwith polythene if not removed from site.The skip will be taken by a licensed carrier to a Licensed tip.A copy of the waste disposal note will be issued to McCarthy & Stone.DDS’s operatives have attended UKATA Asbestos Operatives Three Day Training Course and the managementteam have attended a UKATA Three Day Asbestos Supervisors course.During the removal operation the following precautions will be taken to ensure that the operatives are notexposed to fibre concentrations above the Control Limits:ooooAt the site induction, the operatives who will be involved in the removal works will undertake athorough induction explaining the respective hazards and control measures, method statement andemergency procedures;All operatives will be issued with FFP3 ori-nasal dust masks or Sundstrom oral / nasal half masks,instructed regarding their correct fitting, cleaning and storage. Face fit tests for operatives using RPEwill be provided;Strict hygiene procedures must be maintained - No smoking, drinking or eating whilst working,remove overalls and wash hands, arms and face thoroughly before meal breaks;All operatives will wear Type 5 disposable overalls of a suitable type that will be regularly disposed ofwhen dirty and not washed then re-worn; andIf during strip out, de-planting or demolition further asbestos based materials are discovered McCarthy &Stone will be notified at once, the area will be sealed off and all works in the immediate area will cease.

document: kpml/dds/inglescourt/methodstatement.doc rev 0date: 12 may 2013page no: 186.0 Scaffold ErectionWhere detailed in the Party Wall awards the external elevations of the building will be enclosed byindependent scaffolds clad in monarflex.The monarflex attached to the scaffold will be heavy-duty, the purpose of which is to provide the necessaryprotection to the general public and neighbouring properties by containing the dust and light debris within thedemolition site.The scaffold, providing protection during the demolition of the external fabric, will be fully boarded at alllevels. Any debris on the boards will be cleared regularly to prevent excessive build up and subsequentoverloading.The scaffold will be double boarded on the bottom lift and a sheet of heavy-duty polythene sandwichedbetween the boards. This will prevent debris dropping through the scaffold.The scaffold will be based off the existing ground.General Scaffold Notes• All scaffolds will be erected in accordance with SG4:10, TG20:08, EN12811 and The Work at HeightRegulations 2005.• A method statement will be issued separately and the design is to be approved.• The scaffold erection and dismantling will be strictly supervised by a competent scaffold foreman inconjunction with our site manager.• The Scafftag system will be operated. All scaffold structures will be commissioned and a handovercertificate obtained prior to use. The scaffold inspection register will be completed and updatedweekly.• The scaffold will be tied around existing structural elements in accordance with good workingpractice.• All scaffolds will be struck progressively along with the demolition, maintaining a height of 1.5mabove all working levels.• The operatives will be in possession of a current CISRS (Construction Industry Scaffolder’s RecordScheme) certificate or similar approved.• All operatives will wear the appropriate P.P.E. including harnesses and comply with the site rules.• The appointed scaffold sub-contractor will be recognised as experienced, accomplished and familiarwith this type of work.In compliance with CDM Regulations 2007, the appointed scaffold sub-contractor will be interviewed to assesscompetence and suitability for the contract.

document: kpml/dds/inglescourt/methodstatement.doc rev 0date: 12 may 2013page no: 197.0 Soft StripThe buildings will be soft stripped ahead of the demolition to remove rubbish, fixtures, fittings and non-loadbearing structures.By soft stripping the buildings the demolition hardcore will be processed more efficiently - all combustiblematerials are removed and contamination of the recycled hardcore is minimised.Vigilance regarding the structural integrity of the buildings will be maintained at all times by operatives andSite Supervisor.When all known hazardous materials have been removed and any live services terminated and confirmed, thesoft stripping of the buildings and subsequent removal of internal debris, can commence.The soft strip materials will be removed by hand and loaded outside the buildings using the existing entrances.A 360° excavator fitted with grapple attachment will remove the debris, segregate and load into skips to beremoved from site.

document: kpml/dds/inglescourt/methodstatement.doc rev 0date: 12 may 2013page no: 207.0 Soft Strip (continued)Working progressively through the buildings the following items will be broken down using a combination ofhand tools ie: Mattock, wrecking bar, sledge hammer, etc in a general soft stripping exercise: -LocationAction• Floors Removal of all floor coverings and carpets etcRemoval of all rubbish, furniture, equipment and stockpiledmaterials• Walls Removal of non load bearing walls, plasterboard and partitions,cills, light fittings and fixed shelvingWood panelling finishes to the walls will be carefully removed forsalvage• Ceilings Removal of any suspended ceiling tiles, plasterboard finishes,suspension systems and light fittings• Doors Panelled doors will be carefully removed for salvage• Toilets Stripping out and removal of all toilet fixtures and fittingsincluding toilet pans, sinks and cubicles• Kitchen Removal of all kitchen equipment, sinks and cupboard units• Electrical and mechanicalservicesRemoval of all surface mounted electrical and mechanical cablingand pipeworkAny work at height will be accessed by using mobile towers or podium steps.Ceiling hangers, trunking, conduit, pipework and other non-structural metalwork will be cut out usingoxygen/propane burning equipment, angle grinder or dismantled mechanically.All materials will be segregated into separate waste streams to remove rubbish, plasterboard, timber andmetal products.By regularly removing the accumulated debris, the potential fire risk, that loose combustible material imposes,is minimised / removed.The debris will be taken off site and a copy of all waste tickets will be issued to McCarthy & Stone as part of theSite Waste Management Plan.

document: kpml/dds/inglescourt/methodstatement.doc rev 0date: 12 may 2013page no: 218.0 Structural DemolitionDEMOLITIONThe removal of the mansard roof will be carriedout using hand held tools accessed from amanriding platform supported by an all terraintelescopic handler.The timber roof trusses will be progressivelydemolished, accessed from the telehandler /man riding platform or scaffold, usingchainsaws or hand held tools and separatedfrom the demolition hardcore material.In accordance with the Party Wall awards theend bay at the northern end of the building willbe demolished using hand held tools accessedfrom the scaffolding.The remainder of the external brickwork wallsand structure will be demolished using a 360°excavator fitted with hydraulic multiprocessorgrapple / bucket attachment. The demolitionoperation will be executed in a controlledmanner.As the demolition progresses the timber joistswill be pulled from the building using the 360°excavator fitted with hydraulic grappleattachment.The reinforced concrete frame and slab will be progressively demolished using a 360° excavator fitted withhydraulic multiprocessor and cracker attachment.Materials will fall within the designated drop zone, away from the site boundaries. Hardcore bunds will becreated with the debris arising to control the spread of demolition debris at ground level.The demolition will be carefully stepped at floor levels so as not to create a totally vertical face.Floor levels will be continuously cleared to prevent overloading of slabs and external walls.The demolition operation will be executed in a controlled manner, ensuring the section being crunched orpulled over is not excessive in size and weight. Where possible, complete elements (plant, equipment, beams,columns, panels) will be lifted down to ground level, in the jaws of the cruncher, where they can be processedmore efficiently.This method will minimise noise emissions and vibration transfer to adjacent properties and thus permitcontinued working throughout the working day.The scaffold will be dismantled as the demolition progresses.

document: kpml/dds/inglescourt/methodstatement.doc rev 0date: 12 may 2013page no: 228.0 Structural Demolition (continued)The 360° excavator operator will be certificated, skilled and very experienced with this method of demolition.A Banksman, in radio contact with the 360° excavator operator, will stand at a safe distance to guide and helpcontrol the demolition process.If dust levels within the site are elevated during the course of the works operatives will wear oral/nasal dustmasks and ensure arms and legs are covered to minimise exposure to the dust.The utilisation of a fine water spray directed at the point of demolition will control dust migration.The quantity of water emitted by the spray will be regulated and controlled to prevent any flooding at groundlevel.If of a suitable quality the bricks will be transferred to a stockpile, away from the demolition zone, to becleaned of mortar and stacked on pallets.The basement, ground bearing slabs, hardstandings and foundations will be broken out using a 360° excavatorfitted with bucket or hydraulic breaker attachment.Where detailed in the Party Wall award foundations will remain in-situ.The tarmac materials will be loaded into 8-wheeled tipper wagons and removed from site.Voids, created by removing the footings, will be backfilled with crushed arisings or graded to level the site.

document: kpml/dds/inglescourt/methodstatement.doc rev 0date: 12 may 2013page no: 238.0 Structural Demolition (continued)The basement box will be battered back (depending upon the location of ground contamination) or backfilledwith selected demolition arisings.MATERIALSAll materials will be segregated into separate waste streams to remove rubbish, timber and metal products.The roof tiles will be salvaged and stacked on pallets to be removed from site. If of a suitable quality the brickswill be transferred to a stockpile, away from the demolition zone, to be cleaned of mortar and stacked onpallets.Hardcore will be taken to an offsite crushing facility for recycling. Timber will be sent off site for reuse orpulping. Metal products will be smelted for reuse.By continuously processing materials arising, unobstructed access around a relatively tidy site is maintained.DDS are licensed to produce, transport and receive/dispose of waste materials so these operations can be kept'in house' at our waste recycling centre at Richborough, Sandwich.A copy of the Duty of Care - Waste Transfer Note, detailing description, producer and carrier of waste, will bekept on site and available for inspection.The debris will be taken off site and a copy of all waste tickets will be issued McCarthy & Stone as part of theSite Waste Management Plan.

document: kpml/dds/inglescourt/methodstatement.doc rev 0date: 12 may 2013page no: 249.0 COSHH Assessment LibraryIn accordance with the COSHH Regulations 2002, made under the Health and Safety at Work etc. Act 1974, thehealth of persons exposed to substances hazardous to health in the workplace will be protected. Theregulations impose duties upon employers and their employees.Substances hazardous to health in the workplace are either materials or products imported into the workplaceor products produced by the processes. DDS will ensure that the exposure of employees to substanceshazardous to health is either prevented or, where this is not reasonably practicable, adequately controlled.So far as is reasonably practicable, the prevention or adequate control of exposure will be secured bymeasures other than personal protective equipment.Where measures taken do not prevent, or provide, adequate control of exposure then, in addition to takingthose measures, DDS will provide employees with, and ensure proper use of, suitable personal protectiveequipment that will adequately control their exposure.A library of COSHH assessments will be attached in conjunction with the method statement.The substances are those expected to be encountered during the course of the demolition works but the list isnot limited.Products used in any asbestos removal process will be included in future documentation and any furthersubstances discovered or used as a result of a change in method will be subsequently added to this section.

document: kpml/dds/inglescourt/methodstatement.doc rev 0date: 12 may 2013page no: 2510.0 Risk Assessment LibrarySimilarly, in accordance with The Management of Health and Safety At Work Regulations 1999 DDS will assessall work practices to be encountered during the contract and produce Risk Assessments referring to the worstcase situation for activities not eliminated by the method of works chosen as defined in the MethodStatement.The Risk Assessment will reflect both the likelihood that harm will occur and its severity to employees andother people who may be affected such as visiting contractors and members of the public.A Risk Assessment is not an end in itself. It is a management tool that allows dangers to be evaluated andsuitable measures to be taken to prevent damage or harm from occurring.A library of Risk Assessments relative to this building will be attached in conjunction with the MethodStatement.The Risk Assessments Library will be updated throughout the contract should conditions change and/or newmethods preferred.

document: kpml/dds/inglescourt/methodstatement.doc rev 0date: 12 may 2013page no: 2611.0 Health and Safety NotesThe Health, Safety and Welfare of operatives, visitors and the general public are of prime importance to theCompany. Our Health & Safety consultants will carry out fortnightly site audits. Copies of the reports will beavailable on site for inspection.All personnel on site will carry out their work in accordance with the Company's Safety Policy. In addition tothe requirements of this policy, the following considerations will also be observed: -ooThe site will be deemed a 'Hard Hat Site' and the wearing of protective helmets, gloves, goggles, hi-visjackets and steel toe-capped boots will be required by both site operatives and visitors at all times. Alloperatives will hold current CSCS cards.All operatives and visitors will be required to report to and sign in a Visitors Book on arrival at site.Visitors will be requested not to enter the working areas until a member of the site staff is available toact as a guide.o All site operatives will be given an induction talk covering the following: -• the Works Method Statement.• the Health and Safety at Work Act.• the Company's Policy for health, safety and welfare.• fire procedures (including the location and use of extinguishers).• first aid - name and location of first aider, introduction to them, position of first aid boxes andrules for their use.• use and availability of protective clothing and equipment.• general hazards in and around work area.• specific hazards in work area• procedures for reporting accidents, injuries and property damage.• safe systems of work, where applicable.• welfare - location of canteens, toilets etc. and any other welfare matters.ooooooooCITB certification, or equivalent, for all 360° excavator operators will be provided. In addition thecertification for the machines will be kept in the site file. Copies of all the relevant information will beissued.Adequate supplies of goggles, gloves, ear defenders, eye protection, dust masks and other safetyequipment will be available on site at all times.A personal protection equipment register will be completed and signed by each operative on receiptof the above.Access platforms, scaffolding, cranes, excavators and lifting equipment will be checked regularly inaccordance with current regulations.All machinery, compressors, pneumatic tools etc. will be fitted with silencers of approved types.All works are to be carried out in accordance with the New Demolition Code of Practice BS6187.All of the works are to be under the direct control of an experienced foreman.Regular toolbox talks will be given to the site operatives.

document: kpml/dds/inglescourt/methodstatement.doc rev 0date: 12 may 2013page no: 2711.0 Health and Safety Notes (continued)oooooWarning signs and notices are to be prominently displayed in and around the site.All access routes are to be kept free from obstructions at all times. Debris materials will becontinuously cleared to prevent excessive build up.Where there is a risk from falling, double handrails are to be erected or all works are to be carried outwith MEWP, scaffolding or tower for safe man access.A First Aider and proper first aid kit, commensurate with the total number of site personnel, is to bemaintained on site.Any future changes to the Method Statement will be agreed with the Contracts Manager prior toexecution and the Method Statement appended accordingly.

document: kpml/dds/inglescourt/methodstatement.doc rev 0date: 12 may 2013page no: 2812.0 ConclusionWhilst this statement has been produced specifically for this contract, should it be necessary to amend,deviate or alter due to safety or any other valid reason, a revised method can be agreed by our respective siterepresentatives and an addendum statement produced. This may take the form of a verbal statement followedup by a written statement.Any changes or variations to the original scope of works may have financial implications.DDS will provide a site team of skilled management and operatives to ensure that the contract is carried outwithin the programme period. All necessary precautions will be taken to prevent any disturbance,inconvenience or nuisance to the occupiers and users of adjoining neighbouring properties and the generalpublic.

APPENDIX A

Site InductionContract Ingles Court, Ingles Road, Folkestone, Kent CT20 2ES Date:ReferenceSite Induction to be given by: DDS Demolition LtdI confirm I have been given information about and understand the following: -• the Method Statements relevant to the project.• the Health and Safety at Work Act.• the Company's Policy for health, safety and welfare; especially dedicated Risk and COSHHassessments.• Site Rules• Fire procedures (including the location and use of extinguishers).• first aid - names and locations of First Aid Appointed Persons and introduction to them, position offirst aid boxes and rules for their use.• use and availability of protective clothing and equipment.• general hazards in and around work area.• specific hazards in work area.• procedures for reporting accidents, injuries and property damage.• safe systems of work, where applicable.• welfare - location of mess room, toilets etc. and any other welfare matters.Signed .............................. Print Name .................................Position ..............................

Site Induction RegisterContract Ingles Court, Ingles Road, Folkestone, Kent CT20 2ES Date:Site Induction to be given by: DDS Demolition LtdOPERATIVESI confirm I have received a Site Induction.NAME SIGNATURE DATEI confirm the above have received the Site Induction.Signed ................................. Print Name .................................Position(Foreman) (Site Manager) (Project Manager) delete as appropriate

Personal Protective Equipment RegisterCONTRACT No:SITE:DATE:Ingles Court, Ingles Road, Folkestone, Kent CT20 2ESHelmetGlovesITEMTYPEStandardConstruction IssueRiggerSupplied By Supplied By Available onDDS .......................... SiteEye ProtectionGogglesHearingProtectionDust ProtectionFoul WeatherGearR.P.EFoot ProtectionHI VisibilityClothingSafetyHarnessClear BurningEar PlugDefenders3M Non ToxicParticleWaterproofJacket & TrousersAir StreamHelmetSafety BootWellingtonsWaistcoatFull BodyInertia ReelSIGNED……………………………………………PRINT NAME……………………………POSITION………………………………………….COMPANY . . ……………………………

Method Statement RegisterContract Ingles Court, Ingles Road, Folkestone, Kent CT20 2ES Date:Method Statement RefMethod Statement to be issued by: DDS Demolition LtdOPERATIVESI confirm I have had an explanation of our Method Statement and understand the Safe Systems of Work employed.NAME SIGNATURE DATEI confirm the above have had the detailed Method Statement, incorporating the necessary Safe Systems of Work, explainedto them for the safe completion of the task.Signed ................................. Print Name .................................Position(Foreman) (Site Manager) (Project Manager) delete as appropriate

Method Statement AddendumContract Ingles Court, Ingles Road, Folkestone, Kent CT20 2ES Date:Prepared By:Method Statement Ref:Authorised By:Signed:Dated:Signed:Dated:Method Statement to be issued by: DDS Demolition Ltd1. SCOPE OF WORKS2. RISK ASSESSMENT CONTROL MEASURES3. PPE4. LABOUR & <strong>PLAN</strong>T5. METHOD

document: CS/DDS/Ingles Court/constructionphaseplan.doc rev 0date: 10th May 2013page no: 436.2 Addendum Method Statements

ContractPrepared By:Signed:Dated:Method Statement AddendumMethod Statement Ref:Authorised By:Signed:Dated:Date:Method Statement to be issued by: DDS Demolition Ltd1. SCOPE OF WORKS2. RISK ASSESSMENT CONTROL MEASURES3. PPE4. LABOUR & <strong>PLAN</strong>T5. METHOD

document: CS/DDS/Ingles Court/constructionphaseplan.doc rev 0date: 10th May 2013page no: 446.2 Addendum Method StatementsThis section will be added to and updated during the course of the contract with specific, detailed methods suchas:-ooAsbestos RemovalDemolition

document: CS/DDS/Ingles Court/constructionphaseplan.doc rev 0date: 10th May 2013page no: 456.3 Method Statement Register

ContractMethod Statement RegisterDate:Method Statement to be issued by: DDS Demolition LtdOPERATIVESI confirm I have had an explanation of our Method Statement and understand the Safe Systems of Work employed.NAME SIGNATURE DATEI confirm the above have had the detailed Method Statement, incorporating the necessary Safe Systems of Work, explainedto them for the safe completion of the task.Signed ................................. Print Name .................................Position(Foreman) (Site Manager) (Project Manager) delete as appropriate

document: CS/DDS/Ingles Court/constructionphaseplan.doc rev 0date: 10th May 2013page no: 467.0 Health & Safety

document: CS/DDS/Ingles Court/constructionphaseplan.doc rev 0date: 10th May 2013page no: 477.1 Introduction

document: CS/DDS/Ingles Court/constructionphaseplan.doc rev 0date: 10th May 2013page no: 487.1 IntroductionThe Health, Safety and Welfare of operatives, visitors and the general public are of prime importance to theCompany. Our Health & Safety consultants will carry out fortnightly site audits. Copies of the reports will beavailable on site for inspection.All personnel on site will carry out their work in accordance with the Company's Safety Policy. In addition to therequirements of this policy, the following considerations will also be observed: -ooThe site will be deemed a 'Hard Hat Site' and the wearing of protective helmets, gloves, goggles, hi-visjackets and steel toe-capped boots will be required by both site operatives and visitors at all times. Alloperatives will hold current CSCS cards.All operatives and visitors will be required to report to and sign in a Visitors Book on arrival at site. Visitorswill be requested not to enter the working areas until a member of the site staff is available to act as aguide.o All site operatives will be given an induction talk covering the following: -• the Works Method Statement.• the Health and Safety at Work Act.• the Company's Policy for health, safety and welfare.• site rules• fire procedures (including the location and use of extinguishers).• first aid - name and location of first aider, introduction to them, position of first aid boxesand rules for their use.• use and availability of protective clothing and equipment.• general hazards in and around work area.• specific hazards in work area• procedures for reporting accidents, injuries and property damage.• safe systems of work, where applicable.• welfare - location of canteens, toilets etc. and any other welfare matters.ooooooooCITB certification, or equivalent, for all 360° excavator operators will be provided. In addition thecertification for the machines will be kept in the site file. Copies of all the relevant information will beissued.Adequate supplies of goggles, gloves, ear defenders, eye protection, dust masks and other safetyequipment will be available on site at all times.A personal protection equipment register will be completed and signed by each operative on receipt ofthe above.Access platforms, scaffolding, cranes, excavators and lifting equipment will be checked regularly inaccordance with current regulations.All machinery, compressors, pneumatic tools etc. will be fitted with silencers of approved types.All works are to be carried out in accordance with the New Demolition Code of Practice BS6187.All of the works are to be under the direct control of an experienced foreman.Regular toolbox talks will be given to the site operatives.

document: CS/DDS/Ingles Court/constructionphaseplan.doc rev 0date: 10th May 2013page no: 497.1 Introduction (continued)ooooooWarning signs and notices are to be prominently displayed in and around the site.All access routes are to be kept free from obstructions at all times. Debris materials will be continuouslycleared to prevent excessive build up.Oxygen and Propane bottles will be stored outside in a lockable cage – the position will be agreed on siteand marked up on the site plan.Where there is a risk from falling, double handrails are to be erected or all works are to be carried outwith MEWP, scaffolding or tower for safe man access.A First Aider and proper first aid kit, commensurate with the total number of site personnel, is to bemaintained on site.Any future changes to the Method Statement will be agreed with the Contracts Manager prior toexecution and the Method Statement appended accordingly.For completed copies of PPE Register, Risk, Manual Handling and COSHH assessments see following sections.

document: CS/DDS/Ingles Court/constructionphaseplan.doc rev 0date: 10th May 2013page no: 507.2 Responsibilities

document: CS/DDS/Ingles Court/constructionphaseplan.doc rev 0date: 10th May 2013page no: 517.2 ResponsibilitiesThe CLIENT must:o Appoint CDM coordinator. *o Appoint Principal Contractor. *o Check competence and resources of all appointees.o Ensure there are suitable management arrangements for the project including welfare facilities.o Allow sufficient time and resources for all stages.o Provide pre-construction information to designers and contractors.o Make sure that the construction phase does not start unless there are suitable welfare facilities, andconstruction phase plan in place.o Provide information relating to the health and safety file to the CDM coordinator.o Retain and provide access to the health and safety file.* There must be a CDM coordinator and principal contractor until the end of the construction phaseThe CDM COORDINATOR must:oooooooAdvise and assist the client with his/her duties.Notify HSE.Co-ordinate health and safety aspects of design work and cooperate with others involved with theproject.Facilitate good communication between client, designers and contractors.Liaise with principal contractor regarding ongoing design.Identify, collect and pass on preconstruction information.Prepare/update health and safety file.The DESIGNER must:ooooEliminate hazards and reduce risks during design.Check client is aware of duties and CDM coordinator has been appointed.Provide information about remaining risks.Provide any information needed for the health and safety file.The PRINCIPAL CONTRACTOR must:oooooooPlan, manage and monitor construction phase in liaison with contractor.Prepare, develop and implement a written plan and site rules. (Initial plan completed before theconstruction phase begins).Give contractors relevant parts of the plan.Make sure suitable welfare facilities are provided from the start and maintained throughout theconstruction phase.Check competence of all appointees.Ensure all workers have site inductions and any further information and training needed for the work.Consult with the workers.In addition the PRINCIPAL CONTRACTOR must ensure:ooooThat there is a communication system to impart health and safety information to contractors (this is likelyto be a regular site meeting with compulsory attendance).That there is co-operation on safety matters between contractors.That the site is secure and will not allow access to those who are not authorised to be on site.Compliance with the Construction Phase Plan, site rules and health and safety legislation by contractorson site.

document: CS/DDS/Ingles Court/constructionphaseplan.doc rev 0date: 10th May 2013page no: 527.2 Responsibilities (continued)The CONTRACTOR must ensure:oooooThat they understand the Construction Phase Plan.That the risks not addressed in the Construction Phase Plan are brought to the attention of the principalcontractor for inclusion in the Construction Phase Plan.That they have a system in place to discuss health and safety matters with their staff and sub-contractors.That they have a system in place for collecting all the necessary information for inclusion in the safety file.That they will undergo a site safety induction training course.

document: CS/DDS/Ingles Court/constructionphaseplan.doc rev 0date: 10th May 2013page no: 537.3 Site Rules

document: CS/DDS/Ingles Court/constructionphaseplan.doc rev 0date: 10th May 2013page no: 547.3 Site RulesThis section details the rules and standards, which relate to all employees at work, contractors and visitors. It is theresponsibility of all to obey these rules and to behave in a safe manner whilst at work.The site rules will be related to the workforce during the Site Induction and a copy of the site rules will be posted inthe site changing room.Deliberate contravention of these rules shall be considered a break in employee's contracts of employment and, atthe discretion of the management, shall lead to instant dismissal.It should also be borne in mind that contravention of the Health and Safety Legislation is a criminal offence andthat prosecution can be taken against the employee by the enforcing authority.