Evaluation and Utilisation of Fish Protein Isolate Products

Evaluation and Utilisation of Fish Protein Isolate Products

Evaluation and Utilisation of Fish Protein Isolate Products

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

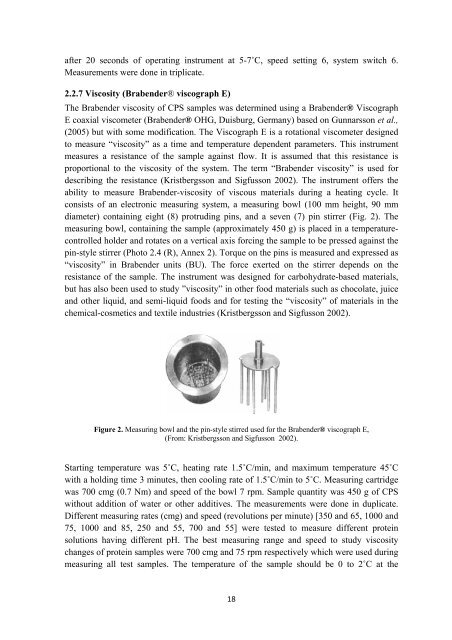

after 20 seconds <strong>of</strong> operating instrument at 5-7˚C, speed setting 6, system switch 6.Measurements were done in triplicate.2.2.7 Viscosity (Brabender® viscograph E)The Brabender viscosity <strong>of</strong> CPS samples was determined using a Brabender® ViscographE coaxial viscometer (Brabender® OHG, Duisburg, Germany) based on Gunnarsson et al.,(2005) but with some modification. The Viscograph E is a rotational viscometer designedto measure “viscosity” as a time <strong>and</strong> temperature dependent parameters. This instrumentmeasures a resistance <strong>of</strong> the sample against flow. It is assumed that this resistance isproportional to the viscosity <strong>of</strong> the system. The term “Brabender viscosity” is used fordescribing the resistance (Kristbergsson <strong>and</strong> Sigfusson 2002). The instrument <strong>of</strong>fers theability to measure Brabender-viscosity <strong>of</strong> viscous materials during a heating cycle. Itconsists <strong>of</strong> an electronic measuring system, a measuring bowl (100 mm height, 90 mmdiameter) containing eight (8) protruding pins, <strong>and</strong> a seven (7) pin stirrer (Fig. 2). Themeasuring bowl, containing the sample (approximately 450 g) is placed in a temperaturecontrolledholder <strong>and</strong> rotates on a vertical axis forcing the sample to be pressed against thepin-style stirrer (Photo 2.4 (R), Annex 2). Torque on the pins is measured <strong>and</strong> expressed as“viscosity” in Brabender units (BU). The force exerted on the stirrer depends on theresistance <strong>of</strong> the sample. The instrument was designed for carbohydrate-based materials,but has also been used to study ”viscosity” in other food materials such as chocolate, juice<strong>and</strong> other liquid, <strong>and</strong> semi-liquid foods <strong>and</strong> for testing the “viscosity” <strong>of</strong> materials in thechemical-cosmetics <strong>and</strong> textile industries (Kristbergsson <strong>and</strong> Sigfusson 2002).Figure 2. Measuring bowl <strong>and</strong> the pin-style stirred used for the Brabender® viscograph E,(From: Kristbergsson <strong>and</strong> Sigfusson 2002).Starting temperature was 5˚C, heating rate 1.5˚C/min, <strong>and</strong> maximum temperature 45˚Cwith a holding time 3 minutes, then cooling rate <strong>of</strong> 1.5˚C/min to 5˚C. Measuring cartridgewas 700 cmg (0.7 Nm) <strong>and</strong> speed <strong>of</strong> the bowl 7 rpm. Sample quantity was 450 g <strong>of</strong> CPSwithout addition <strong>of</strong> water or other additives. The measurements were done in duplicate.Different measuring rates (cmg) <strong>and</strong> speed (revolutions per minute) [350 <strong>and</strong> 65, 1000 <strong>and</strong>75, 1000 <strong>and</strong> 85, 250 <strong>and</strong> 55, 700 <strong>and</strong> 55] were tested to measure different proteinsolutions having different pH. The best measuring range <strong>and</strong> speed to study viscositychanges <strong>of</strong> protein samples were 700 cmg <strong>and</strong> 75 rpm respectively which were used duringmeasuring all test samples. The temperature <strong>of</strong> the sample should be 0 to 2˚C at the18