- Page 1 and 2:

Irrigation Professionals with quest

- Page 3 and 4:

Plot PlansIntroductionOne of the mo

- Page 5 and 6:

Drawing ToolsThere are just a few t

- Page 7 and 8:

Measure the PropertyTake careful me

- Page 9 and 10:

Trees, water meters, and other item

- Page 11 and 12:

Step 2 - Redraw On Graph PaperThe n

- Page 13 and 14:

SymbolsIn order to distinguish betw

- Page 15 and 16:

Make sure the drawing is dated and

- Page 17 and 18:

Step 4 - Group Sprinklers Into Zone

- Page 19 and 20:

Basic HydraulicsIntroductionHydraul

- Page 21 and 22:

How Pressure is Created By the Weig

- Page 23 and 24: Does the Shape or Size of the Conta

- Page 25 and 26: L O W24 VAC 50-60 Hz60mA INRUSH60mA

- Page 27 and 28: Factors Affecting Dynamic PressureW

- Page 29 and 30: INSIDE DIAMETER (i.d.) of the pipe:

- Page 31 and 32: LENGTH is the fourth factor affecti

- Page 33 and 34: D) SDR -Standard Dimension Ratio -

- Page 35 and 36: 1. Look in the left column (FLOW G.

- Page 37 and 38: SummaryThere is a limited amount of

- Page 39 and 40: DefinitionsUse the diagram below al

- Page 41 and 42: Calculating Dynamic Pressure at Des

- Page 43 and 44: D. Estimate Pressure Available at

- Page 45 and 46: Line #5 - Service Line: This is the

- Page 47 and 48: Line #11 - Volume Through the Meter

- Page 49 and 50: C. Calculate Dynamic Pressure at De

- Page 51 and 52: Line #16 - Pressure Loss in the Wat

- Page 53 and 54: Line #21 - Pressure Change Due to E

- Page 55 and 56: Design ProblemMany times, you will

- Page 57 and 58: III. Systems Supplied by a PumpCalc

- Page 59 and 60: D. Estimate Pressure Available at

- Page 61 and 62: Line #5 - Pressure at POC: If the P

- Page 63 and 64: Sample Problem: 13.5 GPMC) Read acr

- Page 65 and 66: D. Estimate Pressure Available at"W

- Page 67 and 68: (METERED SYSTEMS)Design Capacity an

- Page 69 and 70: (METERED SYSTEMS)Design Capacity an

- Page 71 and 72: (METERED SYSTEMS)Design Capacity an

- Page 73: (METERED SYSTEMS)Design Capacity an

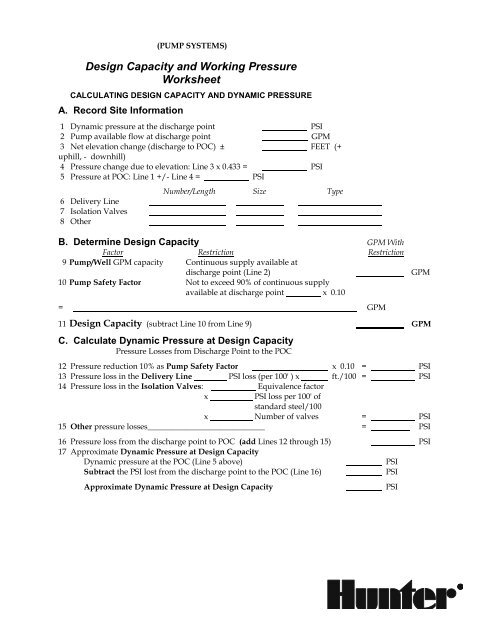

- Page 77 and 78: (PUMP SYSTEMS)Design Capacity and W

- Page 79 and 80: Sprinkler SelectionIntroductionThe

- Page 81 and 82: Spray HeadsFixed spray heads may be

- Page 83 and 84: Selecting the Proper SprinklerNow t

- Page 85 and 86: Precipitation RateExpressed in inch

- Page 87 and 88: Sprinkler Watering PatternsMost spr

- Page 89 and 90: Choosing Nozzles for Gear Driven Ro

- Page 91 and 92: 5) Sprinkler Watering Patterns - Be

- Page 93 and 94: HydrozonesA hydrozone is a portion

- Page 95 and 96: Triangular spacing is usually the p

- Page 97 and 98: and flow rate, the smaller the spri

- Page 99 and 100: perpendicular (see Figure 33). Many

- Page 101 and 102: “symmetrical” layout, and they

- Page 103 and 104: Head spacing in narrow areas is det

- Page 105 and 106: Head placement is complicated becau

- Page 107 and 108: Figure 40PGJ

- Page 109 and 110: On larger slopes, a combination of

- Page 111 and 112: SummarySprinkler head placement is

- Page 113 and 114: Backflow PreventionIntroductionBack

- Page 115 and 116: System LayoutLaying out a system be

- Page 117 and 118: Backflow Preventer LocationLocal pl

- Page 119 and 120: time. Station run time can be tempo

- Page 121 and 122: Pipe Sizing Using the Friction Loss

- Page 123 and 124: Backflow Preventer and Valve Sizing

- Page 125 and 126:

Friction LossesIntroductionCalculat

- Page 127 and 128:

5. Multiply your answer by the leng

- Page 129 and 130:

Friction Loss CalculationsZone Numb

- Page 131 and 132:

Sample Problem:1.67= 0.0167 psi los

- Page 133 and 134:

Step 2Step 3Step 4Step 5Step 6Sprin

- Page 135 and 136:

Using the acceptable 10% allowance:

- Page 137 and 138:

SummaryCalculating the friction los

- Page 139 and 140:

Friction Loss CalculationsZone Numb

- Page 141 and 142:

Friction Loss CalculationsZone Numb

- Page 143 and 144:

Precipitation RatesIntroductionToda

- Page 145 and 146:

Sprinkler Precipitation RatesVersus

- Page 147 and 148:

Area CoveredArc by Sprinkler Flow90

- Page 149 and 150:

The Sprinkler Spacing MethodThis me

- Page 151 and 152:

Use of Precipitation Rates in Lands

- Page 153 and 154:

Irrigation SchedulingIntroductionUl

- Page 155 and 156:

Crop coefficient. Different plants

- Page 157 and 158:

ET Evaporation of soil surface wate

- Page 159 and 160:

Soil Intake RateSoil texture will p

- Page 161:

What You Need to KnowAs previously