- Page 1:

ManagingCo

- Page 5:

Contents51377Introduction. Introduc

- Page 8 and 9:

IntroductionThis field guide is int

- Page 10 and 11:

IntroductionContaminated</s

- Page 12 and 13:

IntroductionContaminated</s

- Page 14 and 15:

IntroductionContaminated</s

- Page 16 and 17:

General Considerations14Disposal of

- Page 18 and 19:

General Considerations16Disposal of

- Page 20 and 21:

General Considerationsprevents scav

- Page 22 and 23:

PlanningPlanning considerations<str

- Page 24 and 25:

Planningunits, rendering plants, <s

- Page 26 and 27:

ProceduresGeneral ConsiderationsPro

- Page 28 and 29:

ProceduresGeneral ConsiderationsFig

- Page 30 and 31:

ProceduresGeneral ConsiderationsFig

- Page 32 and 33:

ProceduresGeneral ConsiderationsFig

- Page 34 and 35:

ProceduresGeneral ConsiderationsFig

- Page 36 and 37:

ProceduresGeneral ConsiderationsFig

- Page 38 and 39:

Safety and Biosecu

- Page 40 and 41:

Safety and Biosecu

- Page 42 and 43:

Safety and Biosecu

- Page 44 and 45:

Safety and Biosecu

- Page 46 and 47:

Safety and Biosecu

- Page 48 and 49:

Safety and Biosecu

- Page 50 and 51:

Safety and Biosecu

- Page 52 and 53:

Safety and Biosecu

- Page 54 and 55:

Safety and Biosecu

- Page 56 and 57:

Safety and Biosecu

- Page 58 and 59:

Safety and Biosecu

- Page 60 and 61:

Safety and Biosecu

- Page 62 and 63:

Safety and Biosecu

- Page 64 and 65:

Safety and Biosecu

- Page 66 and 67:

Safety and Biosecu

- Page 68 and 69:

Safety and Biosecu

- Page 70 and 71:

Safety and Biosecu

- Page 72 and 73:

Safety and Biosecu

- Page 74 and 75:

Safety and Biosecu

- Page 76 and 77:

CostEconomic factorsThe relevant ec

- Page 78 and 79:

CostGeneral ConsiderationsTable 12.

- Page 80 and 81:

Thermalon piles of organic material

- Page 82 and 83:

ThermalDescriptionFixed-facility in

- Page 84 and 85:

ThermalDescriptionties, transportat

- Page 86 and 87:

ThermalDescriptionFigure 2. An air-

- Page 88 and 89:

ThermalSummaryFigure 3. Open-air bu

- Page 90 and 91:

Regulatory SynopsisThermalCoordinat

- Page 92 and 93:

Planning• Ash disposal• Firefig

- Page 94 and 95:

PlanningDo not:• Burn carcasses w

- Page 96 and 97:

PlanningThermalPlanning for open-ai

- Page 98 and 99:

ProceduresThermalProcedure for fixe

- Page 100 and 101:

ProceduresThermalProcedure for open

- Page 102 and 103:

ProceduresThermalFigure 4. Side vie

- Page 104 and 105:

SafetyThermalTable 4. Personal prot

- Page 106 and 107:

SafetyDiseases of concernViruses <s

- Page 108 and 109:

SafetyAdministration suggests estab

- Page 110 and 111:

Environmental ImpactsThermalGroundw

- Page 112 and 113:

Environmental ImpactsThermalAdditio

- Page 114 and 115:

CostDirect costsThermalThe direct f

- Page 116 and 117:

CostThermalTable 6. Estimates of di

- Page 118 and 119:

CostThermalFigure 6. Formulas to es

- Page 120 and 121:

BurialDefinition and</stron

- Page 122 and 123:

BurialTrench burialIn the trench bu

- Page 124 and 125:

BurialSummaryThe leachate from the

- Page 126 and 127:

BurialMass burial is an engineered

- Page 128 and 129:

Regulatory SynopsisBurialCoordinati

- Page 130 and 131:

PlanningPlanning considerationsCons

- Page 132 and 133:

PlanningAlso when locating a burial

- Page 134 and 135:

PlanningTrain the members of the di

- Page 136 and 137:

PlanningPlanning for trench burialW

- Page 138 and 139:

PlanningPlanning for mass burialThe

- Page 140 and 141:

ProceduresProcedure for trench buri

- Page 142 and 143:

ProceduresBurialFigure 1. Length ca

- Page 144 and 145:

ProceduresProcedure for lan

- Page 146 and 147:

ProceduresProcedure for mass burial

- Page 148 and 149:

ProceduresBurialFigure 5. Great Ort

- Page 150 and 151:

SafetyBurialTable 5. Guide<

- Page 152 and 153:

Safetyenvironmental degradation. Th

- Page 154 and 155:

Environmental ImpactsBurialGroundwa

- Page 156 and 157:

Environmental ImpactsBurialtors, wh

- Page 158 and 159:

CostBurialTable 6. Estimates of dir

- Page 160 and 161:

CostBurialEstimating the costs of f

- Page 162 and 163:

CompostingSummaryTable 1. Methods c

- Page 164 and 165:

CompostingIn the first phase of com

- Page 166 and 167: CompostingSummaryFigure 2. An examp

- Page 168 and 169: CompostingSummaryEnd productThe end

- Page 170 and 171: CompostingFigure 3. Carcasses on to

- Page 172 and 173: CompostingSummaryFigure 6. Loading

- Page 174 and 175: CompostingFigure 8. A 200-foot-long

- Page 176 and 177: Compostingparameters such as moistu

- Page 178 and 179: CompostingSummaryFigure 12. Two vie

- Page 180 and 181: Regulatory synopsisCoordination <st

- Page 182 and 183: PlanningPlanning considerationsWhen

- Page 184 and 185: PlanningCompostingTable 2. Carcass

- Page 186 and 187: PlanningComposting184Planning for i

- Page 188 and 189: PlanningCompostingTable 3. Minimum

- Page 190 and 191: Proceduresposting materials). These

- Page 192 and 193: ProceduresCompostingFigure 15. Cros

- Page 194 and 195: ProceduresUse self-propelled or tow

- Page 196 and 197: ProceduresCompostingOdor evaluation

- Page 198 and 199: Procedurescompacting the windrow ba

- Page 200 and 201: Proceduresprevent the contamination

- Page 202 and 203: ProceduresCompostingProcedures for

- Page 204 and 205: SafetyDiseases of concernComposting

- Page 206 and 207: BiosecurityOf paramount importance

- Page 208 and 209: Environmental ImpactsCompostingAir

- Page 210 and 211: CostComposting208Table 5. Initial i

- Page 212 and 213: CostCompostingFigure 18. Formulas f

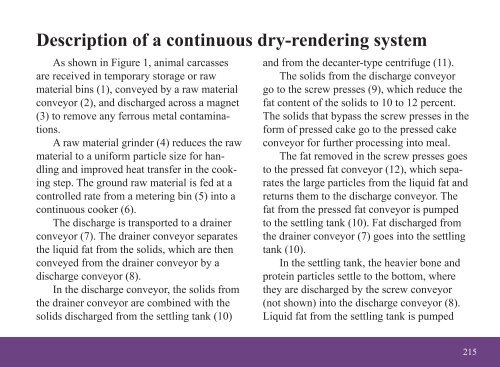

- Page 214 and 215: RenderingDefinition and</st

- Page 218 and 219: Renderinginto the centrifuge (11),

- Page 220 and 221: RenderingSummaryFigure 2. Two views

- Page 222 and 223: Regulatory SynopsisRenderingPolluti

- Page 224 and 225: PlanningRenderingTable 1. Some of t

- Page 226 and 227: ProceduresKeep unauthorized personn

- Page 228 and 229: SafetyRenderingTable 2. Personal pr

- Page 230 and 231: SafetyOnce the safety of the render

- Page 232 and 233: BiosecurityThe air flowing through

- Page 234 and 235: Environmental ImpactsRenderingSome

- Page 236 and 237: CostRenderingTable 3. Estimates of

- Page 238 and 239: CostRenderingFigure 4. (Continued)I

- Page 240 and 241: Alkaline hydrolysisSummaryTable 1.

- Page 242 and 243: Alkaline hydrolysisSummaryFigure 2.

- Page 244 and 245: Alkaline hydrolysisSummaryGeneral d

- Page 246 and 247: Regulatory SynopsisAlkaline hydroly

- Page 248 and 249: PlanningPlanning considerationsAlka

- Page 250 and 251: ProceduresAlkaline hydrolysisTable

- Page 252 and 253: ProceduresAlkaline hydrolysisMobile

- Page 254 and 255: ProceduresAlkaline hydrolysisFigure

- Page 256 and 257: SafetyAlkaline hydrolysisTable 3. P

- Page 258 and 259: SafetyNotes on safetyHeat stress: S

- Page 260 and 261: Environmental Impacts Alkaline hydr

- Page 262 and 263: CostCosts and issu

- Page 264 and 265: CostAlkaline hydrolysisTable 6. Est

- Page 266 and 267:

CostAlkaline hydrolysisFigure 7. (C

- Page 268 and 269:

DigestionSummaryTable 1. Methods co

- Page 270 and 271:

Digestioncannot be recovered with a

- Page 272 and 273:

Digestion3. Acetogenesis: The volat

- Page 274 and 275:

DigestionA sequential-batch system

- Page 276 and 277:

Regulatory SynopsisDigestionCoordin

- Page 278 and 279:

Regulatory SynopsisDigestionThe dec

- Page 280 and 281:

PlanningDigestionFigure 3. Operatio

- Page 282 and 283:

PlanningTo prevent explosions, prov

- Page 284 and 285:

ProceduresDigestioning the mixed ma

- Page 286 and 287:

ProceduresCarcass biogas production

- Page 288 and 289:

SafetyDigestionTable 2. Gui

- Page 290 and 291:

SafetyExposure to extremely high te

- Page 292 and 293:

Environmental ImpactsDigestionGroun

- Page 294 and 295:

CostThe cost breakdown for anaerobi

- Page 296 and 297:

CostDigestionTable 4. Estimates per

- Page 298 and 299:

CostDigestionFigure 8. Formulas to

- Page 300 and 301:

Emerging MethodsSummaryDefinition <

- Page 302 and 303:

Emerging MethodsSummaryGasification

- Page 304 and 305:

Emerging MethodsSummaryTable 1. Gas

- Page 306 and 307:

Emerging MethodsSummaryFigure 3. Vi

- Page 308 and 309:

Emerging MethodsSummaryFigure 4. An

- Page 310 and 311:

Emerging MethodsSummaryThermal depo

- Page 312 and 313:

Emerging MethodsSummarydried animal

- Page 314 and 315:

Emerging MethodsSummaryOther consid

- Page 316:

Emerging MehodsSummaryAlternative d