Corrigendum 01 of Tender 05 of 2013

Corrigendum 01 of Tender 05 of 2013

Corrigendum 01 of Tender 05 of 2013

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

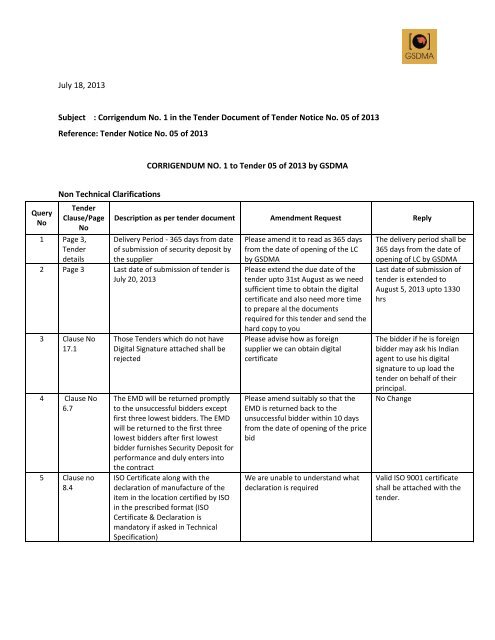

July 18, 2<strong>01</strong>3Subject : <strong>Corrigendum</strong> No. 1 in the <strong>Tender</strong> Document <strong>of</strong> <strong>Tender</strong> Notice No. <strong>05</strong> <strong>of</strong> 2<strong>01</strong>3Reference: <strong>Tender</strong> Notice No. <strong>05</strong> <strong>of</strong> 2<strong>01</strong>3CORRIGENDUM NO. 1 to <strong>Tender</strong> <strong>05</strong> <strong>of</strong> 2<strong>01</strong>3 by GSDMAQueryNoNon Technical Clarifications<strong>Tender</strong>Clause/PageNo1 Page 3,<strong>Tender</strong>detailsDescription as per tender document Amendment Request ReplyDelivery Period - 365 days from date<strong>of</strong> submission <strong>of</strong> security deposit bythe supplier2 Page 3 Last date <strong>of</strong> submission <strong>of</strong> tender isJuly 20, 2<strong>01</strong>33 Clause No17.14 Clause No6.75 Clause no8.4Those <strong>Tender</strong>s which do not haveDigital Signature attached shall berejectedThe EMD will be returned promptlyto the unsuccessful bidders exceptfirst three lowest bidders. The EMDwill be returned to the first threelowest bidders after first lowestbidder furnishes Security Deposit forperformance and duly enters intothe contractISO Certificate along with thedeclaration <strong>of</strong> manufacture <strong>of</strong> theitem in the location certified by ISOin the prescribed format (ISOCertificate & Declaration ismandatory if asked in TechnicalSpecification)Please amend it to read as 365 daysfrom the date <strong>of</strong> opening <strong>of</strong> the LCby GSDMAPlease extend the due date <strong>of</strong> thetender upto 31st August as we needsufficient time to obtain the digitalcertificate and also need more timeto prepare al the documentsrequired for this tender and send thehard copy to youPlease advise how as foreignsupplier we can obtain digitalcertificatePlease amend suitably so that theEMD is returned back to theunsuccessful bidder within 10 daysfrom the date <strong>of</strong> opening <strong>of</strong> the pricebidWe are unable to understand whatdeclaration is requiredThe delivery period shall be365 days from the date <strong>of</strong>opening <strong>of</strong> LC by GSDMALast date <strong>of</strong> submission <strong>of</strong>tender is extended toAugust 5, 2<strong>01</strong>3 upto 1330hrsThe bidder if he is foreignbidder may ask his Indianagent to use his digitalsignature to up load thetender on behalf <strong>of</strong> theirprincipal.No ChangeValid ISO 90<strong>01</strong> certificateshall be attached with thetender.

6 Clause no12.137 Clause no6.6 and 6.7The bidder should arrangedemonstration <strong>of</strong> equipment / goods<strong>of</strong>fered as and when desired at theirexpense failing which his / theirtender shall liable to be ignored. Incase where samples are required tobe submitted, it should be keptready and submitted as and whendemanded in duly sealed packsuperscribed with details <strong>of</strong> <strong>Tender</strong>Notice No., Due Date, Name andAddress <strong>of</strong> Bidder, make / Modeletc. failing which <strong>of</strong>fer shall liable tobe rejected.Additional SD shall be furnished bythe bidder as decided by GSDMA atthe time <strong>of</strong> entering into contract, ifany.Please delete this and other similarclauses as they are not relevant tothis tenderdelete this clauses or please providedetailed clarification about the needfor this clauseThe clause no 12.13 isdeleted for the currenttenderNo ChangeAny shortfall in the value <strong>of</strong> the BankGuarantee, as a result <strong>of</strong>encashment by GSDMA either in fullor in part, shall be made good by theSupplier within 7 (seven) days <strong>of</strong>notice by GSDMA to the Supplier inthis behalf. Any failure by theSupplier to furnish the BankGuarantee or to enhance the Value<strong>of</strong> the Bank guarantee as statedabove shall constitute a default bythe Supplier for which GSDMA shall,without prejudice to any other rightor remedy available to it, be entitledto terminate the Contract withconsequences as indicated in Clause13.4, the provisions where<strong>of</strong> shallmutatis mutandis apply8 Clause no 7 Terms <strong>of</strong> Payment Please conform that all importduties, taxes and levies as applicablein India at the time <strong>of</strong> Import will bepaid directly by GSDMA to theconcerned departments/ authoritiesThe bidder will quoteseparate cost for vehicle i.e.CIF cost and cost in foreigncurrency for the otherservices in India to clear theconsignment from customsand Port. The payment shallbe made in Indian Rupee totheir agent equivalent t<strong>of</strong>oreign currency they havequoted for this service. Therate <strong>of</strong> conversion shall beRBI reference rate on thelast date <strong>of</strong> submission <strong>of</strong>

tenders.9 Clause no16.210 Clause no22.211 Page 34,Qualificationcriteria12 Page 55,Format <strong>of</strong>EMDSample <strong>of</strong> the goods / stores /material(s) shall be collected byInspector(s) <strong>of</strong> any authorizedrepresentative <strong>of</strong> GSDMA in themanner approved by the CEO,GSDMA, and will be sent for testingto an approved laboratory /institution. Testing fee will berecovered from the supplier. Thedecision <strong>of</strong> the testing authority willbe conclusive and final and bindingon the supplier. In all supplies,inspection & testing charges shall bepayable by the Supplier.For delivery <strong>of</strong> goods / stores /material(s) at site, the insuranceshall be obtained by the Supplier inan amount equal to 110% <strong>of</strong> thevalue <strong>of</strong> the goods from "warehouseto warehouse" (final destinations) on"All Risks" basis including War Risksand Strikes.The period <strong>of</strong> “last three financialyears” shall be from <strong>01</strong>.04.2<strong>01</strong>0 to31.03.2<strong>01</strong>3 and “last five financialyears” shall be from <strong>01</strong>.04.2008 to31.03.2<strong>01</strong>3Please delete this and other similarclauses as they are not relevant tothis tenderPlease note that it is not possible toobtain Insurance on “Warehouse toWarehouse basis” The insurance willbe from Warehouse to port <strong>of</strong>discharge. Please amend suitablyOur financial year is from 1st Januaryto 31st December – hence cannotprovide the documents for the year2<strong>01</strong>3. Please amend suitablyWe request you to kindly confirmthat the attached format <strong>of</strong> BG(which is in accordance with UniformRules for Demand Guarantees, ICCPublication No. 458) extracted fromearlier GSDMA tenders is alsoacceptable for submission <strong>of</strong> EMD inform <strong>of</strong> BG.The clause no 16.2 isdeleted for the currenttenderNo ChangeThe bidder shall provide thedetails according to the lastthree financial years andlast five financial yearsirrespective <strong>of</strong> the start andclosing date <strong>of</strong> the financialyear.The bank guarantee formatattached with the tendershall only be acceptable

13 Page 22Section IITerms andconditions<strong>of</strong> contractClause 7PaymentTermsThe payment shall be made to theSupplier as under: (a) AdvancePayment: Ten (10) percent <strong>of</strong> thecontract price shall be paid withinthirty (30) days <strong>of</strong> signing <strong>of</strong> thecontract and upon submission <strong>of</strong>claim and a bank guarantee forequivalent amount valid until thevehicles and equipment aredelivered and in the form providedin the bidding document or anotherform acceptable to the Purchaser.(This bank guarantee is a secondbank guarantee in addition to theBank Guarantee for Security Deposit)(b) On Shipment: Eighty (80) percent<strong>of</strong> the contract price <strong>of</strong> the goodsshipped shall be paid throughirrevocable confirmed letter <strong>of</strong> creditopened in favor <strong>of</strong> the supplier in abank in its country, upon submission<strong>of</strong> documents as mentioned inClause 21 <strong>of</strong> Section II <strong>of</strong> the <strong>Tender</strong>document (c) On Acceptance: Ten(10) percent <strong>of</strong> the contract price <strong>of</strong>goods received shall be paid withinthirty (30) days <strong>of</strong> receipt <strong>of</strong> thegoods upon submission <strong>of</strong> claimsupported by the acceptancecertificate issued by the Purchaser.14 Page 3 Last date <strong>of</strong> submission <strong>of</strong> tenderTechnical as well as Price bid <strong>of</strong>fer15 Page 7,Clause 6.1EMD <strong>of</strong> Euro 68,000The price bid should be in two parts.One part would be the CIF Prices tobe quoted by the OEM in foreigncurreny for which the tenderedpayment terms shall apply. Theother part shall be the cost <strong>of</strong> InlandTransportation, C & F charges at theport and other misc. Charges thatmay be applicable at the time <strong>of</strong>bringing the vehicle from port t<strong>of</strong>inal destination payable to theIndian Authorized Representative inINDIAN RUPEES. Since Import dutiesand taxes vary on currency exchangerate as well as the duty structurefixed by the Central Govt., the sameshould not be included in the scope<strong>of</strong> the bidder. Therefore the ImportDuty, CVD and other statutorycharges payable by an importer shallbe directly paid to the customsdepartment by GSDMAVema factories and <strong>of</strong>ficies remainclosed during the month <strong>of</strong> July forAnnual Summer Holidays. It wouldnot be possible to get BankGuarantees as well as a detaileddocuments as required inPrequalification Criteria. The bidclosing date may please be extendeduntil end <strong>of</strong> August 2<strong>01</strong>3.It is requested to lower the EMDamount.Ref Query no 8Refer Query no 2No Change16 Clause 6.5page 817 Page 4 Point4EMD in the form <strong>of</strong> BG valid for 6monthsPrice BidSince the bid validity is also 6months, should the BG validity bemore than that?Is foreign currency accepted inonline bids? We can quote only CIFprice in foreign currency. Theapplicable customs duty will becalculated by customs when theshipment arrives. Will there beNo ChangeRef Query no 8

provision to quote Indian ServiceCharges in INR separately?18 Page 26,clause 16.119 Page 34,QualificationcriteriaInspection & TestingAuthorized dealer experienceHow many <strong>of</strong>ficials would be sent forinspection?The experience criteria asked inthese sections pertain to themanufacturer or the dealer as well?Please clarifyThe inspection <strong>of</strong> vehiclewill be carried out by threepersonsThe experience criteriaasked in these sectionspertain to theManufacturer’s experience

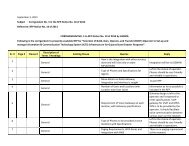

QueryNoTechnical Clarifications<strong>Tender</strong>Clause/PageNo Description as per tender document Amendment Request Reply1 Clause No 3.2 Height to working cage bottom : 53 mtrs Please specify the cage load at working height<strong>of</strong> 53 mtrs – It should be the SWL as specifiedin clause no 3.62 Clause No 5.2 All the operations shall be electrohydraulicallyoperated with the help <strong>of</strong>hydraulic cylinders and chains / Wireropes for telescopic function and for cageleveling system. The system shall bepurpose built to provide smooth take<strong>of</strong>f,variable speed range and smoothslowdown (buffering system) based onthe criteria laid down under EN 1777 &EN280 or any other relevant standardsapplicable for these kind <strong>of</strong> vehicles.3 Clause No 5.3 There shall be two or three booms: thefirst main boom with telescopicextensions providing direct movementand the other articulated boom withvertical movement <strong>of</strong> approx. 180degrees, there shall preferably a thirdboom with vertical movement <strong>of</strong> approx.130 degrees to enable a person climbdown from the cage to the ladder on thesecond boom. The other booms shallprovide an up-and-over capability <strong>of</strong>approx. 12 m throughout its verticalmovement. Based on the selectedoutrigger position and cage load, thesystem selects automatically themaximum outreaches to all directions.The system capacity shall enable variousoutreach curves for each direction. Theworking area <strong>of</strong> the boom shall be dividedin to 15 to 17 sectors. The size <strong>of</strong> eachsector shall automatically be definedbased on position <strong>of</strong> outriggers. Theoutreach control system shall practicallybe infinitely variable.4 Clause No 9.2 The Jacks shall be H-type construction,each outrigger shall have two separatehydraulic cylinders, the first <strong>of</strong> whichpushes the horizontal outrigger beam outand the second shall push the vertical Jackdown.We suggest that the words wire rope should bedeleted as Chains are more safer and sturdierwhich lasts much longer than wire ropes andare relatively maintenance free.Please clearly state the number <strong>of</strong> boomsrequiredWe suggest that the remote control should beable to allow all operations including Autoleveling - We fail to understand why autoleveling requirement has been excluded.Please amend suitablyThe height <strong>of</strong> theHydraulic platform shallbe 53 mtrs withspecified SWL 450 Kgs.In the cage, Noreduction <strong>of</strong> SWL incage is allowed at theheight <strong>of</strong> 53 mtrs.No ChangeThe vehicle shall eitherbe provided with twoor three booms. The 3 rdboom should beindependentNo Change

5 Clause No11.16 Clause No11.37 Clause No13.18 Clause No20.19 Clause No30.1 & 30.2The working cage shall be fixed to thethird articulated boom (optional), in sucha way that there is a safe and easy way toand from the boom ladders through aninward opening door <strong>of</strong> the cage rear side.No climbing over the cage railing will beallowed. The working cage should fullycomply with the safety requirement <strong>of</strong>EN1777 & EN 280.The cage shall be designed for 450 Kgworking load and shall be tested with 25% dynamic overload.There shall be a separate battery drivenHydraulic pump, which providesindependent means <strong>of</strong> hydraulic power incase <strong>of</strong> failure <strong>of</strong> main engine. The batterypump can be operated from all controlpanels. There shall be a separate singlecylinder diesel engine <strong>of</strong> HATZ make,(silent pack) mounted at suitable placewhich will provide independent means <strong>of</strong>hydraulic power in case <strong>of</strong> failure <strong>of</strong> mainengine <strong>of</strong> vehicle. The Diesel engine shallhave sufficient power to drive all themovements <strong>of</strong> the booms but at areduced speed. The Engine shall be ableto start from all control panels.The monitor shall be made <strong>of</strong> light alloyand fitted with jet / fog nozzle <strong>of</strong> Akronmake with maximum capacity <strong>of</strong> 3800LPM.The manufacturer’s service engineer shallundertake the training for a week in theoperation (for at least 8 people) andmaintenance (For at least 2 people) <strong>of</strong> theaerial ladder platform for the operationalstaff. Cost on this account shall beincluded in the <strong>of</strong>fer.The training regarding the repairs,maintenance, <strong>of</strong> the chassis and AerialLadder Platform including all systems shallbe imparted to the engineers/ workshopstaff <strong>of</strong> the Fire Service staff for a period<strong>of</strong> one week at the Fire service HQ /training center. The successful tenderershall supply free <strong>of</strong> cost all the tools andaccessories required for the training.Please specify whether you want the thirdboom or not instead <strong>of</strong> making it OptionalPlease specify that the cage SWL shall betested with the operational boom fullyextended.We suggest that a hand pump shall also beprovided apart from the battery pump andDiesel pump for the back up <strong>of</strong> the hydraulicsystem. Please amend suitablyPlease amend to read as Akron or TFT makePlease clarify whether the total duration <strong>of</strong> thetraining will be one week or two weeksThe specs allow two orthree boom designsubject to compliance<strong>of</strong> requirement <strong>of</strong> otherconditions <strong>of</strong> thisclause.The testing <strong>of</strong> the cageshall be as perparameters specified inthe standards inDynamic and staticconditions.No ChangeThe monitor shall bemade <strong>of</strong> light alloy andfitted with jet / fognozzle <strong>of</strong> Akron orElkart or TFT make withmaximum capacity <strong>of</strong>3800 LPM.The supplier has toprovide one weektraining for operationand handling <strong>of</strong> vehicleto fire brigadeoperational personneland one week servicetraining for engineers.10 Clause No 32 Inspection Please specify the duration <strong>of</strong> the inspection The inspection shall befor the total/completeunit minimum for 4

days.11 Clause 1.5 The working height <strong>of</strong> the Aerial LadderPlatform shall not be less than 53 mtrs(cage bottom)The cage bottom height <strong>of</strong> the Aerial LadderPlatform shall not be less than 53 meters fromthe Ground and the Horizontal workingoutreach with 450 Kg Cage Load shall not beless than 23 meters12 Clause 3.2 Height to working cage bottom : 53 mtrs Please confirm that the cage bottom height <strong>of</strong>53 meters shall be available with full safeworking load <strong>of</strong> 450 Kgs. No reduction inworking load from 450 Kgs shall be acceptablefor 53 meter cage bottom height13 clause 5.2 All the operations shall be electrohydraulicallyoperated with the help <strong>of</strong>hydraulic cylinders and chains / Wireropes for telescopic function and for cageleveling system.14 Clause 5.3 There shall be two or three booms: thefirst main boom with telescopicextensions providing direct movementand the other articulated boom withvertical movement <strong>of</strong> approx. 180degrees, there shall preferably a thirdboom with vertical movement <strong>of</strong> approx.130 degrees to enable a person climbdown from the cage to the ladder on thesecond boom.15 Clause 9.19 In addition, the following controls shall beprovided on jack control panel: A fullfunctional cordless remote with a 100metres range to be provided for the allboom and water monitor movements,except for auto leveling system.The same may be amended to ”chain” only.Wire ropes can cause maintanence as well assafety issue in longer run. By diluting suchimportant safety aspect, it is possible that annon-safe product may be quoted bymanufacturers.A three boom system is much better than a 2boom system. Not only does it facilitates easyentry in to the cage, independantly movingthird boom can provide more versatility inoperations for the operators in case if difficultlocations are to be accessed. We have attacheda few drawings and pictures showing how thethree boom system with independent control<strong>of</strong> the third boom can be more advantageous.We request you to amend the clause as under :There shall be three booms, the first mainboom with telescopic extensions providingdirect movement and the other articulatedboom with vertical movement <strong>of</strong> approx. 180degrees, and the third boom with verticalmovement <strong>of</strong> approx. 130 degrees. The otherbooms shall provide an up-and-over capability<strong>of</strong> min. 12 m throughout its verticalmovement. The cage boom should haveindependent functioning Controls and shall notbe a mere member <strong>of</strong> the cage leveling systemWe do not understand why a very importantfeature such as ’Auto Levelling’ is to be left out<strong>of</strong> the Cordless Remote Control. Any reputedmanufacturer must be able to provide thisfeature on the cordless remote control. Out <strong>of</strong>all other functions, the Auto Levelling Functionis the utmost function that requries a CordlessRemote Control. Hence the the word ’exceptfor’ must be replaced with ’including’Refer Query No 1Refer Query No 1No ChangeRefer Query No 3No Change

16 Clause 11.1 The working cage shall be fixed to thethird articulated boom (optional), in sucha way that there is a safe and easy way toand from the boom ladders through aninward opening door <strong>of</strong> the cage rear side17 Clause 11.2 The cage shall be made <strong>of</strong> tubularaluminium pr<strong>of</strong>ile with high durability.18 Clause 11.3 The cage shall be designed for 450 Kgworking load and shall be tested with 25% dynamic overload19 Clause 26.1 The system shall incorporate simple testscreens to enable testing <strong>of</strong> the workingcage and the turntable control panels. Thetests shall also cover display unit, pushbuttons, joysticks and control lamps20 Clause No 2.1 The chassis shall be Volvo make FM 4008x421 Clause No 2.5 The gearbox should be fully automatictypeThe word ’Optional’ must be removed. All themanufacturers do have a Hydraulic Platformwhich has a three boom system. Allowing suchrelaxation will only allow inferior products tobe quoted. When the cage is attached to thethird boom, the entry into the cage from theladders become very easy. Please see thepicture for a better understanding. Our supply<strong>of</strong> 55 meter unit to Ahmedabad Fire Servicemay be inspected and compared with a 2boom system available with Gandhinagar FireService for better understanding <strong>of</strong> the aspect.Cage made out <strong>of</strong> Stainless Steel are muchbetter in terms <strong>of</strong> longer life and corrossionresistance. Stainless Steel is much better incomparision to Aluminium since the cage willbe constantly subjected to water, foam, heatand hence corrossion. Hence the MOC bechanged to Stainless Steel.Please add the following: The cage load <strong>of</strong> 450Kgs shall be available for operation even whenthe third boom (i.e. the cage boom) is fullyextended.Vema Control Systems are 'SELF DIAGNOSTICFULL FEEDBACK' Systems. This means thatwhen a component like a Joystick, Push Buttonetc fails, the indication immediately is shownon the main display. Hence, our system doesnot require any test screens for testing <strong>of</strong> suchcomponents. Please confirm this is acceptable.The Bronto F55 RLX is light enough to bemounted on 6x4 Volvo FM400 as the GVW is31 tons against permissible GVW <strong>of</strong> 35 tons <strong>of</strong>the Volvo chassis. Please see attachedquotation drawing. Please allow 6x4 chassis aswell.The I-Shift automated gear box would bebetter for the Volvo trucks in our opinion. It isa electronically controlled splitter and rangechangetransmission designed for automaticgear changing with the possibility <strong>of</strong> manualshifts. Attached is some information. Pleaseallow I-Shift automatic gear box as well.22 Clause No 3.3 Cage load is 450 kg It is suggested to improve the parameter to500 kg as it can now be supplied by othersuppliers as well. Can this be amended to 500kg?23 Clause No 3.1 Maximum outrigger width mentioned is7.0 metersIn F55 RLX this is 8,0 m giving the superioroutreach possibilities, see also the attachedoutreach diagram. Because <strong>of</strong> the variablejacking according to our opinion there is notany reason for restricting the max outriggerwidth. Anyhow, with this 7,0m outrigger widthRefer Query no 5The cage shall be made<strong>of</strong> tubular/squarealuminium/ stainlesssteel/steel pr<strong>of</strong>ile withhigh durability.Refer Query No 6No ChangeNo ChangeThe specificationsstipulates fullyautomatic transmissionwhich means there isno need for changingthe gears by drivers andthere shall be no clutchpedal. If I shift fallsunder this categorythen it is acceptable.No Change.No Change

24 Clause No 5.3 Up and over capability <strong>of</strong> approx. 12 m isrequired25 Clause No 5.5 The first boom shall be able to elevate inthe range <strong>of</strong> -3 degree to +85 degree.26 Clause No 9.1 All jacks and horizontal beams shall behot-dip galvanized for better corrosionprotection.27 Clause No 9.3 Each wheel shall be provided with <strong>of</strong>fgroundsensors28 Clause No 9.2 The stabilizing system shall alsoincorporate axle-locking mechanismthe required outreach is available in F55 RLXunit. Do you have any objections to this?In F55 RLX it is 10.5 meters. This is due todifferent boom designs <strong>of</strong> differentmanufacturers. Please note that the BrontoF55 RLX provides much more benefitsexceeding your specifications including lighterin weight, more outreach, more cage load etc.Please accept 10.5 meters and amend.In F55 RLX this is 0 to 84 degrees. When therequired down reach is reached in F55 RLX, 6meters is achieved instead <strong>of</strong> the required 5meters, therefore the minus angle has nomeaning. According to our opinion the range <strong>of</strong>the 1 st boom should be deleted or changedfrom 0 to 84 degrees.Ours is paint technique for corrosionprotection. Please accept and amend.In Bronto F55 RLX, it is a built-in safetymechanism in the outrigger operation that ischecking that the wheels are <strong>of</strong>f the groundand only then allowing the boom movements.The safety feature as required by you is therebut in a different way. Please accept andamend.This used to be case many years ago. But now,the axle lock is not necessary in our Bronto F55RLX units anymore. Please accept and amend.29 Clause No 9.2 Wireless remote control The wireless remote control is not installed atthe outrigger panel. Are the features 9.19.1 to9.19.6 asked to be provided in the wirelessremote control or on the outrigger panel?There is a separate radio remote control foroutrigger with 20 meter range if required byyou. Please see attached. We do provide 100meters range Radio remote control for allboom and water monitor movements. Pleaseclarify.Up and over capabilityspecified is approx. 12m which means weallow +/- 10 %.The first boom shall beable to elevate in suchway and angle that itshall allow to raise acage upto the height <strong>of</strong>53 mtrs (upto cagebottom) and also thedown reach <strong>of</strong> the cageshall be nor less than 5mtrs. Preferably theangle <strong>of</strong> first boom shallbe between -3 to +85degree.All jacks and horizontalbeams shall be hot-dipgalvanized or shotblasted for bettercorrosion protectionbefore painting.Each wheel shall beprovided with <strong>of</strong>fgroundsensors or thejack legs shall haveground pressuresensors and systemshould not allow to liftthe booms unless thereis enough groundpressure on jacks andvehicle is correctlylevelled.The stabilizing systemshall also incorporateaxle-locking mechanismif required.No Change

30 Clause No11.231 Clause No11.732 Clause No17.733 Clause No18.1The cage shall be made <strong>of</strong> tubularaluminium pr<strong>of</strong>ile with high durability.The dimensions <strong>of</strong> the working cage shallbe approx. 2.0 m (length) x 1.0 m (width) x1.1 m (height) and it shall be fitted withfour inward opening doors located atsuitable places to enable safe access tothe cage.The dimensions <strong>of</strong> the rescue platformshall be approx. 1.2 m 0.6 mAn overload warning system shall befitted to give audible and visual warning incase <strong>of</strong> exceeding the safe working loadand boom movements shall be stopped.The system/ mechanism shall be manuallyoverridden by push button.The bodywork requirement is stainlesssteel pr<strong>of</strong>iles.Bronto F55 RLX has a steel cage, which is morefire endurance and stronger compared toaluminum. According to our opinion, work cagefrom steel tube frame shall be accepted. Pleasenote we have much larger work cage. Therequirement for four doors is not realistic, but3 doors shall be sufficient. Please accept andamend.In Bronto F 55 RLX it is 1.36m x 0.5m. Pleaseaccept and amend.In the case <strong>of</strong> overload, the Bronto systemallows for only inward movements to allowsafely to retract. In our opinion, the manualover-ride button can cause harm if theoperator is allowed to operate outwards.Please accept and amend.We are using aluminium pr<strong>of</strong>iles for bodywork.Please accept and amend..The cage shall be made<strong>of</strong> tubular/squarealuminium/stainlesssteel/steel pr<strong>of</strong>ile withhigh durability. Thedimensions <strong>of</strong> theworking cage shall beapprox. 2.0 m (length) x1.0 m (width) x 1.1 m(height) and it shall befitted with three or fourinward opening doorslocated at suitableplaces to enable safeaccess to the cage.The dimensions <strong>of</strong> therescue platform shallnot be less than 1.25 mlength X 0.5 m width.An overload warningsystem shall be fitted togive audible and visualwarning in case <strong>of</strong>exceeding the safeworking load and boommovements shall bestopped and only allowretraction movementonly. The manuallyoverridden system/mechanism shallpreferably be providedfor tactical manoeuvresin case <strong>of</strong> extremeemergency.The bodyworkrequirement is stainlesssteel or aluminiumpr<strong>of</strong>iles34 Page 50Clause no 31Warranty for complete unit includingchassis for 24 months35 Clause No. 1.1 It shall comprise <strong>of</strong> main boom withTelescopic sections and one or twoArticulated BoomsBronto provides warranty for thesuperstructure <strong>of</strong> the Aerial Ladder Platform.The chassis warranty will be provided by thechassis manufacturer’s <strong>of</strong>fice in India, Volvo inthis caseWe suggest two sections shall be used onearticulated and one telescopicThe chassis is integralpart <strong>of</strong> hydraulicplatform and same isprocured directly bysuper structuremanufacturer hencethe supplier should giveback to back warrantyfor chassis from thedate <strong>of</strong> commissioning<strong>of</strong> vehicle at finaldestination.No Change

36 Clause No. 5.3 There shall be two or three booms: thefirst main boom with telescopicextensions providing direct movementand the other articulated boom withvertical movement <strong>of</strong> approx. 180degrees, there shall preferably a thirdboom with vertical movement <strong>of</strong> approx.130 degrees to enable a person climbdown from the cage to the ladder on thesecond boom37 Clause No. 5.8 All necessary hydraulic, electric, air etc.lines up to the cage shall be installedinside the booms, thus being wellprotected38 Clause No. 9.6 The automatic jacking system shall becontrolled by handheld remote controlbox provided with backlit push buttons forfollowing operations39 Clause No.17.1140 Clause No.24.1There shall be a “bleed down” system,which can be operated from working cageand turntable control panels, to lower thebooms and bring the working cage downonto the ground even if no hydraulicpressure is available with manual rotationmechanismA telescopic rescue ladder system shall beattached on the right hand side <strong>of</strong> thebooms. The design shall be such that itforms a direct and continuous rescue waywith no crossover platforms or similarobstacles at the boom jointsWe suggest against use <strong>of</strong> more articulatedbooms for security reasonsPlease note that this design is globally criticizednow because <strong>of</strong> maintenance issues (In case <strong>of</strong>leakages it will not be immediately visible, ashousing is inside). For any maintenance(hydraulic or electrical) the booms will have tobe dismounted. Thus, better design would beto have all necessary hydraulic , electrical , airetc lines to be mounted outside the booms forbetter accessability for maintenance. Pleasealso note only one manufacturer uses this type<strong>of</strong> constructionPlease note as per the EN1777 there must be acontrol command located on each side <strong>of</strong> thevehicle in order to have a clear view <strong>of</strong> eachstabilizer. Remote control is not allowed.Again, this type <strong>of</strong> construction is being usedby only one manufacturerPlease note that as per EN1777 Bleed downsystem is not allowed because <strong>of</strong> safetyreasonsPlease note that a larger number <strong>of</strong> articulatedsections and rescue ladders shall increase risk<strong>of</strong> fall/injuryRefer Query No 3No ChangeAll the European ALPmanufacturers aremaking vehiclescomplying to EN 1777and we will ensure typetest certificate <strong>of</strong>particular model at thetime <strong>of</strong> documentscrutiny.No ChangeNo ChangeR BannerjiCEO, GSDMA