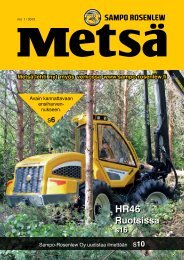

HR46 HARVESTER - Sampo-Rosenlew

HR46 HARVESTER - Sampo-Rosenlew

HR46 HARVESTER - Sampo-Rosenlew

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>HR46</strong> <strong>HARVESTER</strong>Thinning Specialist

The history of <strong>Sampo</strong> <strong>Rosenlew</strong> forest machinesThe founder of <strong>Sampo</strong> <strong>Rosenlew</strong>, mr Timo Prihti was born andraised on a farm. In Finland this means that he was used to workhard not only on the fields but also and especially in the forest.In this environment mr Prihti learned that it is not only fields thatrequire constant attention but also forest. It must be managed – andmanaged well.When mr Prihti in early 1990’s decided to continue the long industrialtraditions of company <strong>Rosenlew</strong> by launching <strong>Sampo</strong> <strong>Rosenlew</strong>,there was a demand for new products. At the same time he noticedthat management of young forest was suffering from lack of manualworkers and lack of suitable machinery. This led to a decision to startproduction of special harvesters for thinning harvesting.<strong>Sampo</strong> <strong>Rosenlew</strong> today<strong>Sampo</strong> <strong>Rosenlew</strong> is a family companyproducing machinery for agriculture andforestry. It is located in Pori, Finland. <strong>Sampo</strong><strong>Rosenlew</strong> designs and produces high qualitycombine harvesters and forest machines.The company was founded 1991. Industrialtraditions start, however, from 1853, when thepredecessor <strong>Rosenlew</strong> was founded. Combineharvester manufacturing was launched1957 and forest machines have been in theproduction since 1997.Mr Prihti is now very pleased to see that it was a good decision.Harvesters manufactured by <strong>Sampo</strong> <strong>Rosenlew</strong> are used to managehundreds of hectares young forest every day. This forest will producehigh quality wood for the needs of future generations.2 The history of <strong>Sampo</strong> <strong>Rosenlew</strong> forest machines3<strong>HR46</strong> Harvester

An enterprise has a future only if it is economically sound and forest is no exception in this rule.Economy in the forestWhen we are growing wood in a forest, we aim atmaximizing the production, and not only in the termsof volume but also in the terms of quality. Whenforest has been generated, the most important toolin controlling the wood production is thinning.The purpose of thinning is to concentrate soilproduction capacity and growth in certain chosentrees. The goal is normally to grow large treeswith high technical quality. The entire land area isreserved for the use of dense, healthy forest.The forest owner/wood producer is merely interestedin what is mentioned above. Technical detailscan only be relevant if they work for correct, goodthinning harvesting.Economy of the contractorForest contracting is economical activitythat must be profitable. Things thatmake it difficult in thinning harvestingare the small yield per hectare and thefact that the remaining trees must notbe damaged. Cost control is the mostefficient tool for a contractor in aiming forprofitability.<strong>Sampo</strong> <strong>Rosenlew</strong> forest machines aredesigned specially keeping in mind theconditions in thinning. Not only are theirtechnical features are very suitable forthinning, but they also are economicallysuperior.Appropriate size for thinning, durabilityand clear construction result to capitaland running costs that are clearly morereasonable than those of the competitors.4 Economy in the forest5<strong>HR46</strong> Harvester

<strong>HR46</strong> HarvesterLess damage to soilProfitable decisions are made in the cabin<strong>Sampo</strong> <strong>Rosenlew</strong> <strong>HR46</strong> cabin is a silent, safeand comfortable place for the operator. Visibilityis good even to tree tops. There are also speciallights on the roof pointing upwards to ensure thenecessary visibility. The outside dimensions andforms are planned to minimize damage for thetrees and for the cabin.<strong>HR46</strong> is easy to useA small harvester is easy to move fromsite to another. Since <strong>Sampo</strong> <strong>Rosenlew</strong><strong>HR46</strong> is a 4-wheel harvester, it is alsopractical to drive on the road. Filters andlubrication points are easy to reach,which helps to make service measuresrapidly. This leaves more time forproductive harvesting work.TRAIL DEPTH<strong>HR46</strong>harvester6 wheelharvesterUnbeatable maneuverability<strong>Sampo</strong> <strong>Rosenlew</strong> <strong>HR46</strong> is specially designed forthinning conditions. The maneuverability of theharvester is unique thanks to big turning angleand small dimensions. This helps the harvesterto move in the terrain and makes the work qualitybetter. It also helps the forwarder to work moreefficiently.Design is very practical<strong>Sampo</strong> <strong>Rosenlew</strong> <strong>HR46</strong>-harvester designis a result of thorough consideration.Maneuvering in the dense young forestrequires that the outer surface is evenand clean. It helps to avoid damagesboth for the remaining trees and for theharvester. Visibility is unlimited to alldirections without blind areas.33 mm 140 mmSoft soil category 3<strong>HR46</strong> - Small but strongPlenty of power is packed in the small dimensionsof <strong>HR46</strong>. The diesel torque is high already inlow rpm. The big hydraulic pump in work circuitutilizes the engine power in full. Harvesting workgoes on swiftly, and the tree trunks are runningthrough the head without pauses.There is reason<strong>Sampo</strong> <strong>Rosenlew</strong> <strong>HR46</strong> – harvester haseverything that is necessary. What is notneeded has been left away. This meansthat the capital and running cost is lowbut the production is, however, higherthan what many heavier competitors cando. HR 46 is the choice of a reasoningcontractor.<strong>Sampo</strong> <strong>Rosenlew</strong> <strong>HR46</strong> wheel size: 650/60-26.56-wheel harvester wheel size front 650/45-22.5 (bogie),rear 650/60-26.5Trail depth comes from a calculation model forforest machine ground pressure and trail depth.This model was developped by the researchinstitutes VTT and Metsäteho Oy. For furtherinformation please consult www.metsateho.fi.6 <strong>HR46</strong> Harvester7<strong>HR46</strong> Harvester

Technical Specification<strong>Sampo</strong>-thinningWeight Weight at work 8, 000-9, 500 kgLength4900 mmWidth2100-2400 mmWheelbase2735 mmGround clearance670 mmHeight3140 mmEngine Agco Power 44 CTA, max. 84 kW @ 2200 rpmFuel tank135 lTransmission Type HydrostaticTurning radius4020 mmSteering angle 50°Speed0-13 km/hTraction force130 kNmWheels Front and rear 500/70-28, 600/55-26.5, 540/65-28, 650/60-26.5Hydraulics Pump Rexroth A10V0 135cc/ 297 l/min/2200 rpmHydraulic oil tank110 lWorking pressure230 barElectrics Batteries 24 V, 2 x 145 AhCharging generator100 ACrane Reach 7,1 mLifting torque, gross55 kNmTurning torque17 kNmHead Keto 51-55Kesla 18RHNisula 400HMax. delimbing diametern. 320 mmcomputerMotomitBrakes Type Multi-disk brakesCabinStandardsWindowsQuiet safety cab(FOPS, ROPS, OPS)12 mm polycarbonate<strong>Sampo</strong><strong>Rosenlew</strong> <strong>HR46</strong> –harvester is able to utilize<strong>Sampo</strong> -thinningmethod. The basic idea is that since thethinning harvester is small and very maneuverable, itcan move in the forest outside the road system, which isopened for the forwarder. This brings many benefits.1. The distance between forwarder roads can beflexibly changed.2. Forwarder road system can be very clear withstraight roads.3. If the terrain is difficult, the roads can be takento the best possible routes.4. After thinning the density of trees is same in allparts of the forest.Limit of the areaStrip road that is openedfor the forwarderRoute where only smallharvester can move10 Specification11<strong>Sampo</strong>-thinning

<strong>Sampo</strong> <strong>Rosenlew</strong> LtdKonepajanranta 2AP.O. Box 50FI-28101 Pori, FinlandTel. +358 207 550 555Fax. +358 2 632 6546www.sampo-rosenlew.fiThis brochure is used globally. The availability of the technical specications, options and accessories described may vary from country to country. Do contact your local dealer to check the latest information. <strong>Sampo</strong> <strong>Rosenlew</strong>reserves the right to make changes to the technical specications, options, accessories, appearance, colours, etc of the forest machine without prior notice in accordance with local conditions or requirements.