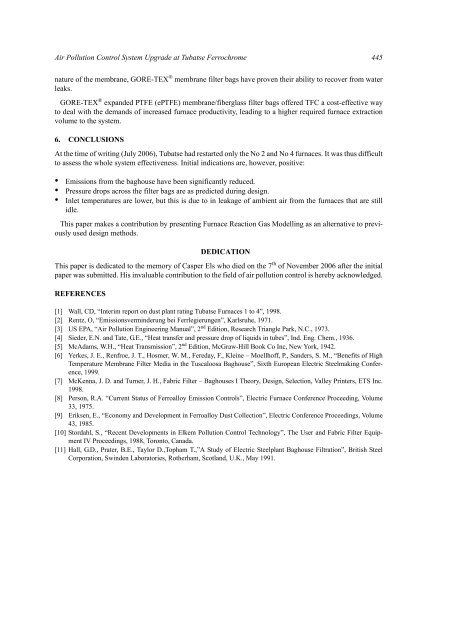

444 INFACON XIPerson [8] has explained the rel<strong>at</strong>ively high filter drag of <strong>co</strong>nventional woven fiberglass m<strong>at</strong>erial when appliedto metallurgical fume. Additionally, one <strong>co</strong>uld reasonably expect higher particul<strong>at</strong>e emissions throughthe <strong>co</strong>nventional fiberglass filter media since the filter cake must be sacrificed to maintain <strong>air</strong>flow. Whilearamid m<strong>at</strong>erial (good to 204°C) in shaker cleaning applic<strong>at</strong>ions shows lower filter drag than woven fiberglassm<strong>at</strong>erial, there is limited experience with aramid in EAF baghouses. Furthermore, in the limited caseswhere aramid had been used in EAF applic<strong>at</strong>ions, the results have not been en<strong>co</strong>uraging.Eriksen [9] and Stordahl [10] reported th<strong>at</strong> GORE-TEX ® membrane/fiberglass filter media has substantiallylower filter drag than <strong>co</strong>nventional media in metallurgical fume applic<strong>at</strong>ions. Previous work by Hall, et al [11]demonstr<strong>at</strong>ed the improved filtr<strong>at</strong>ion efficiency of GORE-TEX ® membrane filter bags in a steel EAF applic<strong>at</strong>ion<strong>at</strong> British Steel when <strong>co</strong>mpared to the results with various woven synthetic filter media <strong>at</strong> the sameinstall<strong>at</strong>ion.Difference Between Conventional and Membrane Fabric Filtr<strong>at</strong>ion TechnologiesWhen fabric filter dust <strong>co</strong>llectors became a viable technology years ago, the available fabric filter media includedwool and <strong>co</strong>ttons, then progressed to polyester, aramid, fiberglass, etc. This method of filtr<strong>at</strong>ion wasand is referred to as <strong>co</strong>nventional depth filtr<strong>at</strong>ion. W. L. Gore & Associ<strong>at</strong>es, Inc. (Gore) introduced expandedpolytetrafluoroethylene (ePTFE) membrane surface filtr<strong>at</strong>ion, offering significant advantages over <strong>co</strong>nventionaldepth filtr<strong>at</strong>ion. The <strong>co</strong>mparison of these two filtr<strong>at</strong>ion methods has been explained a number of timesin the liter<strong>at</strong>ure including the paper by Yerkes [6] <strong>co</strong>mparing the performance of polyester and GORE-TEX ®filter bags <strong>at</strong> Corus Tuscaloosa Steel.200X 600X 200X 600XFigure 9: Scanning Electron Microphotograph: Fiberglass Fabric vs ePTFE MembraneThe lower filter drag typical of GORE-TEX ® membrane filters reduces the <strong>system</strong> resistance and allowsincreased gas flow through the baghouse. With proper inspection and maintenance, GORE-TEX ® membrane/acid resistant fiberglass fabric filter bags oper<strong>at</strong>e effectively for many years. In most cases, even after fiveyears, the GORE-TEX ® membrane filter bags do not show a drop in gas flow capability or filtering efficiency.Elverd, et al [6] documented the improved furnace evacu<strong>at</strong>ion, longer bag life, lower maintenance <strong>co</strong>st, anddecreased particul<strong>at</strong>e emissions <strong>at</strong> Tennessee Alloys Corpor<strong>at</strong>ion after the install<strong>at</strong>ion of GORE-TEX ® expandedPTFE (ePTFE) membrane/fiberglass filter bags in 1993. Substantially all of those filter bags werestill in service after eight years.W<strong>at</strong>er leaks are a <strong>co</strong>mmon problem in EAF fume tre<strong>at</strong>ment <strong>system</strong>s. These w<strong>at</strong>er leaks, if carried over tothe baghouse, will blind <strong>co</strong>nventional filter media in a short time period. Since the <strong>air</strong>flow through <strong>co</strong>nventionalmedia does not re<strong>co</strong>ver after an extended w<strong>at</strong>er leak, new bags are required. Due to the hydrophobic

Air Pollution Control System Upgrade <strong>at</strong> Tub<strong>at</strong>se Ferrochrome 445n<strong>at</strong>ure of the membrane, GORE-TEX ® membrane filter bags have proven their ability to re<strong>co</strong>ver from w<strong>at</strong>erleaks.GORE-TEX ® expanded PTFE (ePTFE) membrane/fiberglass filter bags offered TFC a <strong>co</strong>st-effective wayto deal with the demands of increased furnace productivity, leading to a higher required furnace extractionvolume to the <strong>system</strong>.6. CONCLUSIONSAt the time of writing (July 2006), Tub<strong>at</strong>se had restarted only the No 2 and No 4 furnaces. It was thus difficultto assess the whole <strong>system</strong> effectiveness. Initial indic<strong>at</strong>ions are, however, positive:• Emissions from the baghouse have been significantly reduced.• Pressure drops across the filter bags are as predicted during design.• Inlet temper<strong>at</strong>ures are lower, but this is due to in leakage of ambient <strong>air</strong> from the furnaces th<strong>at</strong> are stillidle.This paper makes a <strong>co</strong>ntribution by presenting Furnace Reaction Gas Modelling as an altern<strong>at</strong>ive to previouslyused design methods.DEDICATIONThis paper is dedic<strong>at</strong>ed to the memory of Casper Els who died on the 7 th of November 2006 after the initialpaper was submitted. His invaluable <strong>co</strong>ntribution to the field of <strong>air</strong> <strong>pollution</strong> <strong><strong>co</strong>ntrol</strong> is hereby acknowledged.REFERENCES[1] Wall, CD, “Interim report on dust plant r<strong>at</strong>ing Tub<strong>at</strong>se Furnaces 1 to 4”, 1998.[2] Rentz, O, “Emissionsverminderung bei Ferrlegierungen”, Karlsruhe, 1971.[3] US EPA, “Air Pollution Engineering Manual”, 2 nd Edition, Research Triangle Park, N.C., 1973.[4] Sieder, E.N. and T<strong>at</strong>e, G.E., “He<strong>at</strong> transfer and pressure drop of liquids in tubes”, Ind. Eng. Chem., 1936.[5] McAdams, W.H., “He<strong>at</strong> Transmission”, 2 nd Edition, McGraw-Hill Book Co Inc, New York, 1942.[6] Yerkes, J. E., Renfroe, J. T., Hosmer, W. M., Fereday, F., Kleine – Moellhoff, P., Sanders, S. M., “Benefits of HighTemper<strong>at</strong>ure Membrane Filter Media in the Tuscaloosa Baghouse”, Sixth European Electric Steelmaking Conference,1999.[7] McKenna, J. D. and Turner, J. H., Fabric Filter – Baghouses I Theory, Design, Selection, Valley Printers, ETS Inc.1998.[8] Person, R.A. “Current St<strong>at</strong>us of Ferroalloy Emission Controls”, Electric Furnace Conference Proceeding, Volume33, 1975.[9] Eriksen, E., “E<strong>co</strong>nomy and Development in Ferroalloy Dust Collection”, Electric Conference Proceedings, Volume43, 1985.[10] Stordahl, S., “Recent Developments in Elkem Pollution Control Technology”, The User and Fabric Filter EquipmentIV Proceedings, 1988, Toronto, Canada.[11] Hall, G.D., Pr<strong>at</strong>er, B.E., Taylor D.,Topham T.,”A Study of Electric Steelplant Baghouse Filtr<strong>at</strong>ion”, British SteelCorpor<strong>at</strong>ion, Swinden Labor<strong>at</strong>ories, Rotherham, S<strong>co</strong>tland, U.K., May 1991.