air pollution control system upgrade at tubatse ... - Pyro.co.za

air pollution control system upgrade at tubatse ... - Pyro.co.za

air pollution control system upgrade at tubatse ... - Pyro.co.za

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

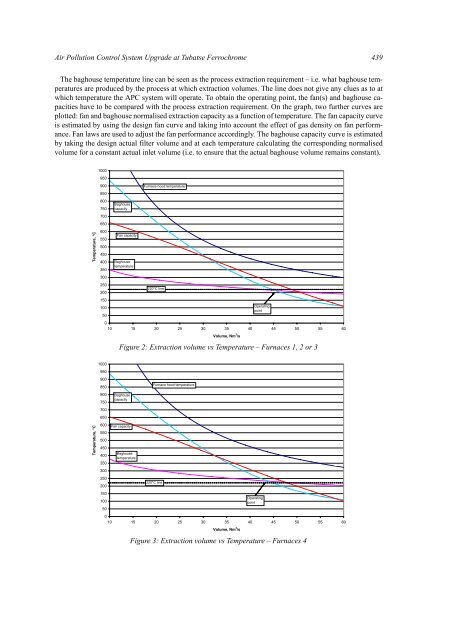

Air Pollution Control System Upgrade <strong>at</strong> Tub<strong>at</strong>se Ferrochrome 439The baghouse temper<strong>at</strong>ure line can be seen as the process extraction requirement – i.e. wh<strong>at</strong> baghouse temper<strong>at</strong>uresare produced by the process <strong>at</strong> which extraction volumes. The line does not give any clues as to <strong>at</strong>which temper<strong>at</strong>ure the APC <strong>system</strong> will oper<strong>at</strong>e. To obtain the oper<strong>at</strong>ing point, the fan(s) and baghouse capacitieshave to be <strong>co</strong>mpared with the process extraction requirement. On the graph, two further curves areplotted: fan and baghouse normalised extraction capacity as a function of temper<strong>at</strong>ure. The fan capacity curveis estim<strong>at</strong>ed by using the design fan curve and taking into ac<strong>co</strong>unt the effect of gas density on fan performance.Fan laws are used to adjust the fan performance ac<strong>co</strong>rdingly. The baghouse capacity curve is estim<strong>at</strong>edby taking the design actual filter volume and <strong>at</strong> each temper<strong>at</strong>ure calcul<strong>at</strong>ing the <strong>co</strong>rresponding normalisedvolume for a <strong>co</strong>nstant actual inlet volume (i.e. to ensure th<strong>at</strong> the actual baghouse volume remains <strong>co</strong>nstant).1000950Temper<strong>at</strong>ure, °C90085080075070065060055050045040035030025020015010050BaghousecapacityFan capacityBaghousetemper<strong>at</strong>ureFurnace hood temper<strong>at</strong>ure220°C lineOper<strong>at</strong>ingpoint010 15 20 25 30 35 40 45 50 55 60Volume, Nm 3 /sFigure 2: Extraction volume vs Temper<strong>at</strong>ure – Furnaces 1, 2 or 31000950Temper<strong>at</strong>ure, °C900Furnace hood temper<strong>at</strong>ure850800 Baghousecapacity750700650600 Fan capacity550500450Baghouse400temper<strong>at</strong>ure350300250220°C line200150Oper<strong>at</strong>ing100point50010 15 20 25 30 35 40 45 50 55 60Volume, Nm 3 /sFigure 3: Extraction volume vs Temper<strong>at</strong>ure – Furnaces 4