air pollution control system upgrade at tubatse ... - Pyro.co.za

air pollution control system upgrade at tubatse ... - Pyro.co.za

air pollution control system upgrade at tubatse ... - Pyro.co.za

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

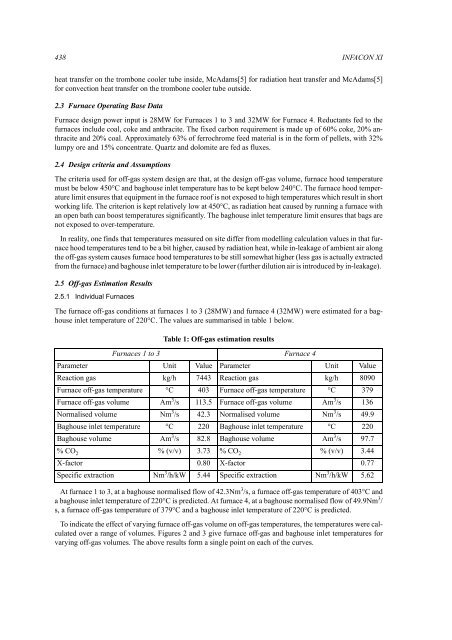

438 INFACON XIhe<strong>at</strong> transfer on the trombone <strong>co</strong>oler tube inside, McAdams[5] for radi<strong>at</strong>ion he<strong>at</strong> transfer and McAdams[5]for <strong>co</strong>nvection he<strong>at</strong> transfer on the trombone <strong>co</strong>oler tube outside.2.3 Furnace Oper<strong>at</strong>ing Base D<strong>at</strong>aFurnace design power input is 28MW for Furnaces 1 to 3 and 32MW for Furnace 4. Reductants fed to thefurnaces include <strong>co</strong>al, <strong>co</strong>ke and anthracite. The fixed carbon requirement is made up of 60% <strong>co</strong>ke, 20% anthraciteand 20% <strong>co</strong>al. Approxim<strong>at</strong>ely 63% of ferrochrome feed m<strong>at</strong>erial is in the form of pellets, with 32%lumpy ore and 15% <strong>co</strong>ncentr<strong>at</strong>e. Quartz and dolomite are fed as fluxes.2.4 Design criteria and AssumptionsThe criteria used for off-gas <strong>system</strong> design are th<strong>at</strong>, <strong>at</strong> the design off-gas volume, furnace hood temper<strong>at</strong>uremust be below 450°C and baghouse inlet temper<strong>at</strong>ure has to be kept below 240°C. The furnace hood temper<strong>at</strong>urelimit ensures th<strong>at</strong> equipment in the furnace roof is not exposed to high temper<strong>at</strong>ures which result in shortworking life. The criterion is kept rel<strong>at</strong>ively low <strong>at</strong> 450°C, as radi<strong>at</strong>ion he<strong>at</strong> caused by running a furnace withan open b<strong>at</strong>h can boost temper<strong>at</strong>ures significantly. The baghouse inlet temper<strong>at</strong>ure limit ensures th<strong>at</strong> bags arenot exposed to over-temper<strong>at</strong>ure.In reality, one finds th<strong>at</strong> temper<strong>at</strong>ures measured on site differ from modelling calcul<strong>at</strong>ion values in th<strong>at</strong> furnacehood temper<strong>at</strong>ures tend to be a bit higher, caused by radi<strong>at</strong>ion he<strong>at</strong>, while in-leakage of ambient <strong>air</strong> alongthe off-gas <strong>system</strong> causes furnace hood temper<strong>at</strong>ures to be still somewh<strong>at</strong> higher (less gas is actually extractedfrom the furnace) and baghouse inlet temper<strong>at</strong>ure to be lower (further dilution <strong>air</strong> is introduced by in-leakage).2.5 Off-gas Estim<strong>at</strong>ion Results2.5.1 Individual FurnacesThe furnace off-gas <strong>co</strong>nditions <strong>at</strong> furnaces 1 to 3 (28MW) and furnace 4 (32MW) were estim<strong>at</strong>ed for a baghouseinlet temper<strong>at</strong>ure of 220°C. The values are summarised in table 1 below.Table 1: Off-gas estim<strong>at</strong>ion resultsFurnaces 1 to 3 Furnace 4Parameter Unit Value Parameter Unit ValueReaction gas kg/h 7443 Reaction gas kg/h 8090Furnace off-gas temper<strong>at</strong>ure °C 403 Furnace off-gas temper<strong>at</strong>ure °C 379Furnace off-gas volume Am 3 /s 113.5 Furnace off-gas volume Am 3 /s 136Normalised volume Nm 3 /s 42.3 Normalised volume Nm 3 /s 49.9Baghouse inlet temper<strong>at</strong>ure °C 220 Baghouse inlet temper<strong>at</strong>ure °C 220Baghouse volume Am 3 /s 82.8 Baghouse volume Am 3 /s 97.7% CO 2 % (v/v) 3.73 % CO 2 % (v/v) 3.44X-factor 0.80 X-factor 0.77Specific extraction Nm 3 /h/kW 5.44 Specific extraction Nm 3 /h/kW 5.62At furnace 1 to 3, <strong>at</strong> a baghouse normalised flow of 42.3Nm 3 /s, a furnace off-gas temper<strong>at</strong>ure of 403°C anda baghouse inlet temper<strong>at</strong>ure of 220°C is predicted. At furnace 4, <strong>at</strong> a baghouse normalised flow of 49.9Nm 3 /s, a furnace off-gas temper<strong>at</strong>ure of 379°C and a baghouse inlet temper<strong>at</strong>ure of 220°C is predicted.To indic<strong>at</strong>e the effect of varying furnace off-gas volume on off-gas temper<strong>at</strong>ures, the temper<strong>at</strong>ures were calcul<strong>at</strong>edover a range of volumes. Figures 2 and 3 give furnace off-gas and baghouse inlet temper<strong>at</strong>ures forvarying off-gas volumes. The above results form a single point on each of the curves.