320386-001 - AO Smith Water Heaters

320386-001 - AO Smith Water Heaters

320386-001 - AO Smith Water Heaters

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Installation Instructions and Use & Care GuideRESIDENTIAL GAS WATER HEATERSFVIR GAS WATER HEATER(FLAMMABLE VAPOR IGNITION RESISTANT)FOR SPACE HEATING AND POTABLE WATER HEATING ONLY.NOT FOR USE IN MOBILE HOMES.This water heater complies with ANSI Z21.10.1-currentedition regarding the accidental or unintended ignition offl ammable vapors, such as those emitted by gasoline.For Your SafetyAN ODORANT IS ADDED TO THE GAS USEDBY THIS WATER HEATER.• Safety Instructions• Installation• Operation• Care and Maintenance• Troubleshooting• Parts ListINSTALLER:• AFFIX THESE INSTRUCTIONS TO OR ADJACENTTO THE WATER HEATER.OWNER:• RETAIN THESE INSTRUCTIONS AND WARRANTYFOR FUTURE REFERENCE. RETAIN THEORIGINAL RECEIPT AS PROOF OF PURCHASE.WARNING: Gas leaks can not always be detected bysmell.Gas suppliers recommend that you use a gas detectorapproved by UL or CSA.For more information, contact the your gas supplier.If a gas leak is detected, follow the “WHAT TO DO IF YOUSMELL GAS” instructions.WARNING: If the information in theseinstructions is not followed exactly, a fireor explosion may result causing propertydamage, personal injury or death.— Do not store or use gasoline or otherflammable vapors and liquids in thevicinity of this or any other appliance.— WHAT TO DO IF YOU SMELL GAS• Do not try to light any appliance.• Do not touch any electrical switch;do not use any phone in yourbuilding.• Immediately call your gas supplierfrom a neighbor’s phone. Follow thegas supplier’s instructions.• If you cannot reach your gassupplier, call the fire department.— Installation and service must beperformed by a qualified installer,service agency or the gas supplier.LOW LEADCOMPLIANTALL TECHNICAL AND WARRANTY QUESTIONS: SHOULD BE DIRECTED TO THE LOCAL DEALER FROM WHOM THE WATER HEATER WAS PURCHASED.IF YOU ARE UNSUCCESSFUL, CONTACT RESIDENTIAL TECHNICAL ASSISTANCE AT 1-800-527-1953 OR WWW.HOTWATER.COM.PRINTED IN THE U.S.A. 1110 1PART NO. <strong>320386</strong>-<strong>001</strong>

TABLE OF CONTENTS<strong>Water</strong> Heater Safety .............................................................................................................................................................................. 1Safe Installation, Use and Service ...................................................................................................................................................... 3Safety Precautions ............................................................................................................................................................................ 3-4Typical Installation ............................................................................................................................................................................... 5Installing your Gas <strong>Water</strong> Heater ..................................................................................................................................................... 6-8Important Information About Your <strong>Water</strong> Heater ...................................................................................................................... 6Consumer Information ............................................................................................................................................................. 6Consumer Responsibilities ...................................................................................................................................................... 6Unpacking the <strong>Water</strong> Heater ................................................................................................................................................... 6Location Requirements ............................................................................................................................................................ 7Site Location ............................................................................................................................................................................ 7Clearances and Accessibility ................................................................................................................................................... 8State of California .................................................................................................................................................................... 8Gas Supply ....................................................................................................................................................................................... 9-10Gas Requirements .................................................................................................................................................................... 9Gas Piping ............................................................................................................................................................................... 9Gas Pressure ........................................................................................................................................................................... 9Gas Pressure Testing ............................................................................................................................................................... 9LP Gas Only ........................................................................................................................................................................... 10Combustion Air and Ventilation ....................................................................................................................................................11-15Unconfined Space ...................................................................................................................................................................11Confined Space ......................................................................................................................................................................11All Air from Inside the Building ............................................................................................................................................... 12All Air from Outdoors .............................................................................................................................................................. 12Louvers and Grilles ........................................................................................................................................................... 12-13Vent Pipe System .................................................................................................................................................................. 13Draft Hood Installation ...................................................................................................................................................... 13-14Vent Pipe Size ....................................................................................................................................................................... 14Vent Connectors .................................................................................................................................................................... 14Chimney Connection .............................................................................................................................................................. 14Vertical Exhaust Gas Vent ................................................................................................................................................ 14-15<strong>Water</strong> System Piping ..................................................................................................................................................................... 15-18Piping Installation .............................................................................................................................................................. 15-16Closed System/Thermal Expansion ....................................................................................................................................... 16Temperature & Pressure Relief Valve .................................................................................................................................... 17T&P Relief Valve and Pipe Installation .................................................................................................................................. 17Combination Space Heating/Potable <strong>Water</strong> System ........................................................................................................ 17-18Solar Installation .................................................................................................................................................................... 18Important Information About this <strong>Water</strong> Heater .............................................................................................................................. 19Operating Your <strong>Water</strong> Heater ....................................................................................................................................................... 20-26Lighting Instructions .......................................................................................................................................................... 20-21Checking the Draft ................................................................................................................................................................. 22Burner Flames ....................................................................................................................................................................... 22Emergency Shutdown ............................................................................................................................................................ 22<strong>Water</strong> Temperature Regulation ......................................................................................................................................... 22-23Operating the Temperature Control System ........................................................................................................................... 23Operational Conditions ..................................................................................................................................................... 23-24Draining and Flushing ............................................................................................................................................................. 25Routine Preventive Maintenance ........................................................................................................................................... 25Temperature and Pressure Relief Valve ........................................................................................................................... 25-26Maintenance of Your <strong>Water</strong> Heater .............................................................................................................................................. 26-29Replacement Parts ................................................................................................................................................................ 26Removing the Burner from the Manifold/Burner Assembly ................................................................................................... 26Replacing the Pilot / Thermopile Assembly ........................................................................................................................... 27External Inspection & Cleaning of the Base-Ring Filter ........................................................................................................ 28Cleaning the Combustion Chamber and Flame-arrestor ....................................................................................................... 28Replacing the Manifold Burner/Assembly ......................................................................................................................... 28-29Piezoelectric Igniter System .................................................................................................................................................. 29Testing the Igniter System ..................................................................................................................................................... 29Removing and Replacing the Gas Control Valve/Thermostat ............................................................................................... 29FVIR System Operational Checklist ...................................................................................................................................... 30Troubleshooting Checklist ........................................................................................................................................................... 30-31Pilot Light Troubleshooting Flowchart ............................................................................................................................................ 32Status Light and Diagnostic Code Troubleshooting Chart ........................................................................................................ 33-34Notes .... ............................................................................................................................................................................................... 35Repair Parts ................................................................................................................................................................................... 36-37Warranty .......................................................................................................................................................................................... 38-392

SAFE INSTALLATION, USE AND SERVICEYour safety and the safety of others is extremely important in the installation, use and servicing of this water heater.Many safety-related messages and instructions have been provided in this manual and on your water heater to warn you andothers of a potential hazard. Read and obey all safety messages and instructions throughout this manual. It is very importantthat the meaning of each safety message is understood by you and others who install, use or service this water heater.This is the safety alert symbol. It is used to alert you to potential personal injury hazards. Obey all safetymessages that follow this symbol to avoid possible injury or death.DANGERWARNINGCAUTIONCAUTIONDANGER indicates an imminently hazardous situation which, if not avoided, willresult in death or injury.WARNING indicates a potentially hazardous situation which, if not avoided, couldresult in death or injury.CAUTION indicates a potentially hazardous situation which, if not avoided, couldresult in minor or moderate injury.CAUTION used without the safety alert symbol indicates a potentially hazardoussituation which, if not avoided, could result in property damageAll safety messages will generally tell you about the type of hazard, what can happen if you do not follow the safety messageand how to avoid the risk of injury.The California Safe Drinking <strong>Water</strong> and Toxic Enforcement Act requires the Governor of California to publish a list ofsubstances known to the State of California to cause cancer, birth defects, or other reproductive harm, and requires businessesto warn of potential exposure to such substances.WARNING: This product contains a chemical known to the State of California to cause cancer, birth defects, or otherreproductive harm.This appliance can cause low-level exposure to some of the substances included in the act.IMPORTANT DEFINITIONS• Qualified Technician: A qualified technician must have ability equivalent to a licensed tradesman in the fields ofplumbing, air supply, venting, and gas supply, including a thorough understanding of the requirements of the NationalFuel Gas Code as it relates to the installation of gas fired water heaters. The qualified technician must also befamiliar with the design features and use of flammable vapor ignition resistant water heaters, and have a thoroughunderstanding of this instruction manual.• Service Agency: A service agency also must have ability equivalent to a licensed tradesman in the fields ofplumbing, air supply, venting and gas supply, including a thorough understanding of the requirements of the NationalFuel Gas Code as it relates to the installation of gas fired water heaters. The service agency must also have athorough understanding of this instruction manual, and be able to perform repairs strictly in accordance with theservice guidelines provided by the manufacturer.• Gas Supplier: The Natural Gas or Propane Utility or service who supplies gas for utilization by the gas burningappliances within this application. The gas supplier typically has responsibility for the inspection and code approval ofgas piping up to and including the Natural Gas meter or Propane storage tank of a building. Many gas suppliers alsooffer service and inspection of appliances within the building.SAFETY PRECAUTIONSWARNINGFLAMMABLESFlammable VaporsFIRE AND EXPLOSION HAZARDCan result in serious injury or deathDo not store or use gasoline or otherflammable vapors and liquids in the vicinity of thisor any other appliance. Storage of or use ofgasoline or other flammable vapors or liquids in thevicinity of this or any other appliance can result inserious injury or death.Read and follow water heater warnings and instructions.3

Fire or Explosion HarzardDo not store or use gasoline or other flammable vapors andliquids in the vicinity of this or any other appliance.Avoid all ignition sources if you smell Natural or LP gas.Do not expose water heater control to excessive gaspressure.Use only gas shown on rating plate.Maintain required clearances to combustibles.Keep ignition sources away from faucets after extendedperiod of non-use.Read instruction manual beforeinstalling, using or servicingwater heater.Fire or Explosion HarzardHydrogen gas can be produced in a hot water system aftera period of non-use (generally two or more weeks).Hydrogen gas is extremely flammable and can ignite.To return hot water system to service, open a hot waterfaucet in kitchen for several minutes before using electricalappliances.Do not smoke or have open flame near faucet while it is open.Leave hot water faucet open until the sound of escapingair stops.After extended period of non-use,purge gases from hot water system.4

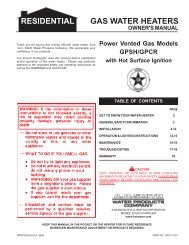

TYPICAL INSTALLATIONGET TO KNOW YOUR WATER HEATER - GAS MODELSA Vent PipeB Draft HoodC Anode (Not Shown)D Hot <strong>Water</strong> OutletE InsulationF Gas Supply PipingG Manual Gas Shut-off ValveH Ground Joint UnionI Drip Leg (Sediment Trap)J Inner DoorK Outer DoorL UnionM Inlet <strong>Water</strong> Shut-off ValveN Cold <strong>Water</strong> InletO Inlet Dip TubeP Temperature-Pressure Relief ValveQ Rating PlateR Flue BaffleS Gas Control Valve/ThermostatT Drain ValveU Manifold/Burner AssemblyV FlueW Metal Drain PanX Piezo IgniterY Base-Ring Filter* INSTALL IN ACCORDANCEWITH LOCAL CODES.* DRIP LEG AS REQUIREDBY LOCAL CODES.(S) GAS CONTROL VALVE/THERMOSTATTO VENTTERMINATION ONROOFGas Control/Temperature KnobStatusLight120°FMarkAINSTALL THERMAL EXPANSIONTANK IF WATER HEATER ISINSTALLED IN ACLOSED WATER SYSTEMVACDBLMNIgniterTemperatures shown are approximates and may vary.OVACUUM RELIEFVALVE*INSTALL PERLOCAL CODES(U) MANIFOLD/BURNER ASSEMBLYREPMAIN BURNERPILOT TUBETHERMOPILEMANIFOLDTUBEQGFMANIFOLD DOORIGNITER WIREHVSDISCHARGE PIPE(DO NOT CAP OR PLUG.)TIU6” MAXIMUMAIR GAPW YJXK* ALL PIPING MATERIALS TO BESUPPLIED BY CUSTOMERS.FLOOR DRAIN5

INSTALLING YOUR GAS WATER HEATERImportant Information About This <strong>Water</strong> HeaterThis gas water heater was manufactured to voluntarysafety standards to reduce the likelihood of a flammablevapor ignition incident. New technology used in meetingthese standards makes this product more sensitive toinstallation errors or improper installation environments.Please review the Installation Checklist found at the end ofthe installation instructions section and make any requiredinstallation upgrades or changes.Consumer InformationThis water heater is design-certified by CSA Internationalas a Category I, non-direct vented water heater whichtakes its combustion air either from the installation area orfrom air ducted to the unit from the outside.This water heater must be installed according to all localand state codes or, in the absence of local and statecodes, the “National Fuel Gas Code”, ANSI Z223.1(NFPA54)-current edition. This is available from the following:CSA America, Inc.8501 East Pleasant Valley RoadCleveland, OH 44131National Fire Protection Agency1 Batterymarch ParkQuincy, MA 02269Check your phone listings for the local authorities havingjurisdiction over your installation.Consumer ResponsibilitiesUnpacking the <strong>Water</strong> HeaterWARNINGExcessive Weight HazardUse two or more people to move and install the water heater.Failure to do so can result in injury (including back injury).IMPORTANT: Do not remove any permanent instructions,labels, or the data label from either the outside of thewater heater or on the inside of water heater panels.• Remove exterior packaging and place installation componentsaside.• Inspect all parts for damage prior to installation andstart-up.• Completely read all instructions before attempting toassemble and install this product.• After installation, dispose of/recycle all packagingmaterials.This manual has been prepared to acquaint you with theinstallation, operation, and maintenance of your gas waterheater and provide important safety information in theseareas.Read all of the instructions thoroughly before attemptingthe installation or operation of this water heater.Do not discard this manual. You or future users of thiswater heater will need it for future reference.Service to the FVIR System should only be performed by aqualified technician.Examples of a qualified technician include: licensedplumbers, authorized gas company personnel, andauthorized service personnel.IMPORTANT: The manufacturer and seller of this waterheater will not be liable for any damages, injuries, ordeaths caused by failure to comply with the installation andoperating instructions outlined in this manual.If you lack the necessary skills required to properly installthis water heater, or you have difficulty following theinstructions, you should not proceed but have a qualifiedtechnician perform the installation of this water heater.Massachusetts code requires this water heater to beinstalled in accordance with Massachusetts Plumbing andFuel Gas Code 248 CMR Section 2.00 and 5.00.A rating plate identifying your water heater can be foundon the front of your water heater. When referring to yourwater heater, always have the information listed on therating plate readily available. Retain your original receiptas proof of purchase.6

Location RequirementsWARNINGCarbon Monoxide Poisoning HazardDo not install in a mobile home.Doing so can result in carbon monoxide poisoning and death.The FVIR System is designed to reduce the risk offlammable vapor-related fires. The patented systemprotects your family by trapping the burning vaporswithin the water heater combustion chamber through thespecial flame-arrestor. The burning vapors literally “burnthemselves out” without escaping back into the room.In the event of a flammable vapor incident, the FVIRSystem disables the water heater by shutting off the gassupply to the water heater’s burner and pilot, preventingre-ignition of any remaining flammable vapors in the area.This will not prevent a possible fire/explosion if the igniteris depressed and flammable vapors have accumulatedin the combustion chamber with the pilot light off. If yoususpect a flammable vapor incident has occurred, do notuse this appliance. Do not attempt to light this appliance,or depress the igniter button if you suspect flammablevapors have accumulated inside or outside the appliance.Immediately call a qualified technician to inspect theappliance. <strong>Water</strong> heaters subjected to a flammable vaporsincident will show a discoloration on the flame-arrestor andrequire replacement of the entire water heater.FLAMMABLESWARNINGFlammable VaporsFIRE AND EXPLOSION HAZARDCan result in serious injury or deathDo not store or use gasoline or other flammablevapors and liquids in the vicinity of this or any otherappliance. Storage of or use of gasoline or otherflammable vapors or liquids in the vicinity of this orany other appliance can result in serious injury ordeath.Read and follow water heater warnings andinstructionsDo not use or store flammable products such as gasoline,solvents, or adhesives in the same room or area near thewater heater. If such flammables must be used, all gasburning appliances in the vicinity must be shut off and theirpilot lights extinguished. Open the doors and windows forventilation while flammable substances are in use.If flammable liquids or vapors have spilled or leaked inthe area of the water heater, leave the area immediatelyand call the fire department from a neighbor’s home. Donot attempt to clean the spill until all ignition sources havebeen extinguished.WARNINGFire or Explosion Hazard• Read instruction manual before installing, using orservicing water heater.• Improper use may result in fire or explosion.• Maintain required clearances to combustibles.Keep combustibles such as boxes, magazines, clothes, etc. awayfrom the water heater area.Site Location• Select a location near the center of the water pipingsystem. The water heater must be installed indoorsand in a vertical position on a level surface. DO NOTinstall in bathrooms, bedrooms, or any occupied roomnormally kept closed.• Locate the water heater as close to the chimney or gasvent as practical. Consider the vent system piping andcombustion air supply requirements when selecting thewater heater location. The venting system must be ableto run from the water heater to termination with minimallength and elbows.• Locate the water heater near the existing gas piping.If installing a new gas line, locate the water heater tominimize the pipe length and elbows.• The water heater should be located in an area notsubject to freezing temperatures. <strong>Water</strong> heaterslocated in unconditioned spaces (i.e., attics,basements, etc.) may require insulation of the waterpiping and drain piping to protect against freezing.The drain and controls must be easily accessible foroperation and service. Maintain proper clearances asspecified on the rating plate.• Do not locate the water heater near an air-movingdevice. The operation of air-moving devices suchas exhaust fans, ventilation systems, clothes dryers,fireplaces, etc., can affect the proper operation of thewater heater. Special attention must be given to conditionsthese devices may create. Flow reversal of fluegases may cause an increase of carbon monoxideinside of the dwelling (Figure 1B).• If the water heater is located in an area that issubjected to lint and dirt, it may be necessary toperiodically clean the base-ring filter and flamearrestor.Refer to the “Maintenance of your <strong>Water</strong>Heater” section.NOTE: This water heater must be installed according to alllocal and state codes or, in the absence of local and statecodes, the “National Fuel Gas Code”, ANSI Z223.1(NFPA54)-current edition.7

GAS SUPPLYWARNINGManual GasShut-off Valve• Use a new CSA approved gas supply line.• Install a shut-off valve.• Do not connect a natural gas water heater to an L.P. gassupply.• Do not connect an L.P. gas water heater to a natural gassupply.• Failure to follow these instructions can result in death,explosion, or carbon monoxide poisoning.Gas RequirementsExplosion HazardCheck with localutility forminimum heightGroundJointUnionGas Pressure3” MinimumDrip LegFIGURE 3.WARNING6” MaximumAir GapIMPORTANT: Read the rating plate to be sure the waterheater is made for the type of gas you will be using inyour home. This information will be found on the ratingplate located near the gas control valve/thermostat. If theinformation does not agree with the type of gas available,do not install or light. Call your dealer.NOTE: An odorant is added by the gas supplier to the gasused by this water heater. This odorant may fade over anextended period of time. Do not depend upon this odorantas an indication of leaking gas.Gas PipingThe gas piping must be installed according to all local andstate codes or, in the absence of local and state codes, the“National Fuel Gas Code”, ANSI Z223.1(NFPA 54)-currentedition.Tables 1 and 2 on the following page provide a sizingreference for commonly used gas pipe materials. Consultthe “National Fuel Gas Code” for the recommended gaspipe size of other materials.NOTE: Use pipe joint compound or teflon tape marked asbeing resistant to the action of petroleum [Propane (L.P.)]gases (See Figure 3.)1. Install a readily accessible manual shut-off valve in thegas supply line as recommended by the local utility.Know the location of this valve and how to turn off thegas to this unit.2. Install a drip leg (if not already incorporated as part ofthe water heater) as shown. The drip leg must be noless than three inches long for the accumulation of dirt,foreign material, and water droplets.3. Install a ground joint union between the gas controlvalve/thermostat and the manual shut-off valve. Thisis to allow easy removal of the gas control valve/thermostat.4. Turn the gas supply on and check for leaks. Test allconnections by brushing on an approved noncorrosiveleak-detection solution. Bubbles will show a leak.Correct any leak found.9Explosion Hazard• Gas leaks can not always be detected by smell.• Gas suppliers recommend that you use a gasdetector approved by UL or CSA.• For more information, contact your gas supplier.• If a gas leak is detected, follow the “What to do if yousmell gas” instructions on the cover of this manual.IMPORTANT: The gas supply pressure must not exceed themaximum supply pressure as stated on the water heater’s ratingplate. The minimum supply pressure is for the purpose of inputadjustment.Gas Pressure TestingIMPORTANT: This water heater and its gas connection mustbe leak tested before placing the appliance in operation.• If the code requires the gas lines to be tested at apressure exceeding 14” W.C., the water heater and itsmanual shut-off valve must be disconnected from the gassupply piping system and the line capped.• If the gas lines are to be tested at a pressure less than14” W.C., the water heater must be isolated from the gassupply piping system by closing its manual shut-off valve.NOTE: Air may be present in the gas lines and could preventthe pilot from lighting on initial start-up. The gas lines shouldbe purged of air by a qualified technician after installation ofthe gas piping system. While purging the gas piping systemof air, insure that the fuel is not spilled in the area of thewater heater installation, or any source of ignition. If thefuel is spilled while purging the piping system of air followthe “WHAT TO DO IF YOU SMELL GAS” instructions onthe cover of this manual.

LP Gas OnlyWARNINGExplosion HazardHave a qualified person make sure L.P. gas pressuredoes not exceed 13” water column.Liquefied petroleum gas is over 50% heavier than airand in the occurrence of a leak in the system, the gaswill settle at floor level. Basements, crawl spaces, closetsand areas below ground level will serve as pockets forthe accumulation of gas. Before lighting an L.P. gas waterheater, smell all around the appliance at floor level. If yousmell gas, follow the instructions as given in the warningon the front page.When your L.P. tank runs out of fuel, turn off the gas atall gas appliances including pilot lights. After the tank isrefi lled, all appliances must be re-lit according to theirmanufacturer’s instructions.Examples of a qualified person include: licensedplumbers, authorized gas company personnel, andauthorized service personnel.Failure to do so can result in death, explosion, or fire.10

COMBUSTION AIR & VENTILATIONWARNINGCarbon Monoxide Warning<strong>Water</strong> heater must be vented to outdoors.Vent must be installed by a qualified technician usingthe installation instructions.Examples of a qualified technican include: gastechnicians, authorized gas company personel, andauthorized service persons.Failure to so do can result in death or carbon monoxidepoisoning.IMPORTANT: Air for combustion and ventilation must notcome from a corrosive atmosphere. Any failure due tocorrosive elements in the atmosphere is excluded fromwarranty coverage.The following types of installation (not limited to thefollowing) will require outdoor air for combustion due tochemical exposure and may reduce but not eliminate thepresence of corrosive chemicals in the air:• beauty shops• photo processing labs• buildings with indoor pools• water heaters installed in laundry, hobby, or craftrooms• water heaters installed near chemical storage areasCombustion air must be free of acid-forming chemicals suchas sulfur, fluorine, and chlorine. These elements are foundin aerosol sprays, detergents, bleaches, cleaning solvents,air fresheners, paint, and varnish removers, refrigerants,and many other commercial and household products. Whenburned, vapors from these products form highly corrosive acidcompounds. These products should not be stored or usednear the water heater or air inlet.Combustion and ventilation air requirements are determinedby the location of the water heater. The water heater maybe located in either an open (unconfined) area or in aconfined area or small enclosure such as a closet or smallroom. Confined spaces are areas with less than 50 cubicfeet for each 1,000 BTUH of the total input for all gas-usingappliances.Unconfined SpaceA water heater in an unconfined space uses indoor air forcombustion and requires at least 50 cubic feet for each1,000 BTUH of the total input for all gas appliances. Thetable below shows a few examples of the minimum squarefootage (area) required for various BTUH inputs.TABLE 3BTUH InputMinimumSquareFeet with8’ CeilingTypical Roomwith 8’ Ceiling30,000 188 9 x 2145,000 281 14 x 2060,000 375 15 x 2575,000 469 15 x 3190,000 563 20 x 28105,000 657 20 x 33120,000 750 25 x 30135,000 844 28 x 30IMPORTANT:• The area must be open and be able to provide theproper air requirements to the water heater. Areas thatare being used for storage or contain large objectsmay not be suitable for water heater installation.• <strong>Water</strong> heaters installed in open spaces in buildingswith unusually tight construction may still require outdoorair to function properly. In this situation, outsideair openings should be sized the same as for a confinedspace.• Modern home construction usually requires supplyingoutside air into the water heater area.Confined SpaceFor the correct and proper operation of this water heater,ample air must be supplied for the combustion, ventilation,and dilution of flue gases. Small enclosures and confinedareas must have two permanent openings so that sufficientfresh air can be drawn from outside of the enclosure. Oneopening shall be within 12 inches of the top and one within12 inches of the bottom of the enclosure as shown inFigure 4.The size of each opening (free area) is determined by thetotal BTUH input of all gas utilization equipment (i.e., waterheaters, furnaces, clothes dryers, etc.) and the method bywhich the air is provided. The BTUH input can be foundon the water heater rating plate. Additional air can beprovided by two methods:1. All air from inside the building.2. All air from outdoors.11

PERMANENTOPENINGS TOTHE OUTSIDE ORADDITIONALROOMS WITHINTHE BUILDING12” MAXIMUM12” MAXIMUMFIGURE 4.All Air from Inside the BuildingCLOSETOROTHERCONFINEDSPACEWhen additional air is to be provided to the confined areafrom additional room(s) within the building, the total volumeof the room(s) must be of sufficient size to properly providethe necessary amount of fresh air to the water heaterand other gas utilization equipment in the area. If you areunsure that the structure meets this requirement, contactyour local gas utility company or other qualified agency fora safety inspection.Each of the two openings shall have a minimum free areaof 1 square inch per 1,000 BTUH of the total input rating ofall gas utilization equipment in the confined area, but notless than 100 square inches (Figure 5).fresh air can be taken from the outdoors or from crawl orattic spaces that freely communicate with the outdoors.Attic or crawl spaces cannot be closed and must beproperly ventilated to the outside.Ductwork must be of the same cross-sectional area asthe free area of the opening to which they connect. Theminimum dimension of rectangular air ducts cannot be lessthan three inches.The size of each of the two openings is determined by themethod in which the air is to be provided. Refer to Table4 to calculate the minimum free area for each opening.Figures 6, 7, 8A and 8B are typical examples of eachmethod.Louvers and GrillesIn calculating free area for ventilation and combustionair supply openings, consideration must be given to theblocking effect of protection louvers, grilles, and screens.These devices can reduce airflow, which in turn mayrequire larger openings to achieve the required minimumfree area. Screens must not be smaller than 1/4” mesh. Ifthe free area through a particular design of louver or grilleis known, it should be used in calculating the specifiedfree area of the opening. If the design and free area arenot known, it can be assumed that most wood louvers willallow 20 - 25% of free area while metal louvers and grilleswill allow 60 - 75% of free area.Louvers and grilles must be locked open or interconnectedwith the equipment so that they are opened automaticallyduring equipment operation.Keep louvers and grilles clean and free of debris or otherobstructions.All Air from OutdoorsCONFINEDSPACEFIGURE 5.PERMANENTOPENINGS1 SQUAREINCH/1000BTUH(MINIMUM100 SQ. IN.)Outdoor fresh air can be provided to a confined area eitherdirectly or by the use of vertical and horizontal ducts. TheTABLE 4Minimum Free Area of Permanent Openings forVentilation and Combustion Air Supply - All Air fromOutdoors Only.Based on total BTUH input rating for all utilizingequipment within the confi ned space.Minimum Free AreaOpening Source Per Opening (sq. in.) Reference Drawing*Direct to outdoors 1 sq. in, per 4000 BTUH Figure 6Vertical Ducts 1 sq. in, per 4000 BTUH Figure 7Horizontal Ducts 1 sq. in, per 2000 BTUH Figure 8ASingle Opening 1 sq. in, per 3000 BTUH Figure 8BExample: A water heater with an input rating of 50,000 BTUH usinghorizontal ducts would require each opening to have a minimum freearea of 25 square inches.Minimum free area = 50,000 BTUH x 1 sq. in. / 2000 BTUH = 25 sq. in.* These openings connect directly with the outdoors througha ventilated attic, a ventilated crawl space, or through anoutside wall.Consult the local codes of your area for specific ventilationand combustion air requirements.12

GABLE VENTTO OUTDOORSINSTALL ABOVEINSULATIONALTERNATIVEOPENINGLOCATIONCONFINEDSPACEOUTLETAIR TOATTIC 1 SQ.INCH PER4000 BTUHCONFINEDSPACE1 SQ. INCHPER 3000 BTUHALTERNATEAIR INLETINLET AIR FROMTHE CRAWL SPACEALL AIR FROM OUTDOORS - USING A SINGLE PERMANENT OPENING1 SQ. INCH PER4000 BTUHOPENFOUNDATIONVENTALL AIR FROM OUTDOORS: INLET AIR FROM VENTILATEDCRAWL SPACE/OUTLET AIR TO VENTILATED ATTICCONFINEDSPACEFIGURE 6.GABLE VENTTO OUTDOORSINSTALL ABOVEINSULATIONOUTLET AIRTO ATTIC1 SQ. INCHPER 4000BTUHINLET AIR DUCT1 SQ. INCH PER4000 BTUH12” MAXIMUMALL AIR FROM OUTDOORS THROUGH VENTILATED ATTICCONFINEDSPACEFIGURE 7.1 SQ. INCH PER2000 BTUHOUTLETOUTDOORAIR DUCTSVent Pipe SystemFIGURE 8B.This water heater uses a non-direct, single-pipe ventsystem to remove exhaust gases created by the burning offossil fuels. Air for combustion is taken from the immediatewater heater location or is ducted in from the outside (see“Combustion Air and Ventilation”).This water heater must be properly vented for the removalof exhaust gases to the outside atmosphere. Correctinstallation of the vent pipe system is mandatory for theproper and efficient operation of this water heater and isan important factor in the life of the unit.The vent pipe must be installed according to all local andstate codes or, in the absence of local and state codes, the“National Fuel Gas Code”, ANSI Z223.1(NFPA 54)-currentedition. The vent pipe installation must not be obstructedso as to prevent the removal of exhaust gases to theoutside atmosphere.IMPORTANT: The use of vent dampers is notrecommended by the manufacturer of this water heater.Although some vent dampers are certified by CSAInternational, this certification applies to the vent damperdevice only and does not mean they are certified for useon this water heater.U.L. recognized fuel gas and carbon monoxide (CO)detectors are recommended in all applications and shouldbe installed using the manufacturer’s instructions and localcodes, rules, or regulations.IMPORTANT: If you lack the necessary skills requiredto properly install this venting system, you should notproceed, but get help from a qualified technician.Draft Hood InstallationSHEET METAL SCREWS (FOUR PROVIDED)INLETLEGSDRAFT HOODLEGS1 SQ. INCH PER2000 BTUHALL AIR FROM OUTDOORS USING HORIZONTAL DUCTSSLOTJACKET TOPINSTALL THE DRAFT HOOD WITHTHE FOUR SCREWS PROVIDED.SLOTFIGURE 8A.13FIGURE 9

Align the legs of the draft hood with the slots provided.Insert the legs and secure the draft hood to the waterheater’s top with the four screws provided as shown inFigure 9. Do not alter the draft hood in any way. If you arereplacing an existing water heater, be sure to use the drafthood supplied with this water heater.Vent Pipe SizeIt is important that you follow the guidelines in theseinstructions for sizing a vent pipe system. If a transitionto a larger vent size is required, the vent transitionconnection must be made at the draft hood outlet.• The connector must be installed above the extremebottom of the chimney to prevent potentially blockingthe flue gases.• The connector must be firmly attached and sealed toprevent it from falling out.• To aid in removing the connector, a thimble or slip jointmay be used.• The connector must not extend beyond the inner edgeof the chimney as it may restrict the space between itand the opposite wall of the chimney (Figure 10).LISTED LINEDCHIMNEYVent Connectors1. Type B, Double wall, U.L. Listed Vent Pipe.2. Single wall Vent Pipe.Maintain the manufacturer’s specified minimum clearancefrom combustible materials when using type B double wallvent pipe.Vent connectors made of type B, double wall vent pipematerial may pass through walls or partitions constructedof combustible material if the minimum listed clearance ismaintained.Maintain a six inch minimum clearance from allcombustible materials when using single wall vent pipe.IMPORTANT: Single wall vent pipe cannot be used forwater heaters located in attics and may not pass throughattic spaces, crawl spaces or any confined or inaccessiblelocation. A single wall metal vent connector cannot passthrough any interior wall.When installing a vent connector, please note the following(See Figures 10-12):• Install the vent connector avoiding unnecessary bends,which create resistance to the flow of vent gases.• Install without dips or sags with an upward slope of atleast 1/4-inch per foot.• Joints must be fastened by sheet metal screws or otherapproved means. It must be supported to maintainclearances and prevent separation of joints anddamage.• The length of the vent connector cannot exceed 75% ofthe vertical vent height.• The vent connector must be accessible for cleaning,inspection, and replacement.• Vent connectors cannot pass through any ceiling, floor,firewall, or fire partition.• It is recommended (but not mandatory) that a minimum12 inches of vertical vent pipe be installed on the drafthood prior to any elbow in the vent system.IMPORTANT: Existing vent systems must be inspected forobstructions, corrosion, and proper installation.Chimney ConnectionIMPORTANT: Before connecting a vent to a chimney,make sure the chimney passageway is clear and free ofobstructions. The chimney must be cleaned if previouslyused for venting solid fuel appliances or fireplaces. Alsoconsult local and state codes for proper chimney sizingand application or, in the absence of local and statecodes, the “National Fuel Gas Code”, ANSI Z223.1(NFPA54)-current edition.143 FT. MINIMUMSUPPORTSTRAPMAINTAINCLEARANCE*SEALSLOPEUP 1/4 IN.PER FT.MINIMUMCHIMNEY TERMINATION VENT SYSTEM2 FT. MINIMUM ABOVE ANY OBJECTWITHIN 10FT. HORIZONTALLYDO NOT EXTENDVENT BEYOND EDGEOF CHIMNEYVENTCONNECTORFIGURE 10.Do not terminate the vent connector in a chimney that hasnot been certified for this purpose. Some local codes mayprohibit the termination of vent connectors in a masonrychimney.Vertical Exhaust Gas VentVertical exhaust gas vents must be installed withU.L. listed type B vent pipe according to the ventmanufacturer’s instructions and the terms of its listing.It must be connected to the water heater’s draft hood by alisted vent connector or by directly originating at the drafthood opening.Vertical gas vents must terminate with a listed cap orother roof assembly and be installed according to theirmanufacturer’s instructions.Gas vents must be supported to prevent damage, jointseparation, and maintain clearances to combustiblematerials (Figures 11 and 12).IMPORTANT: This gas vent must be terminated in avertical position to facilitate the removal of the burnt gases.An unused chimney flue or masonry enclosure may be usedas a passageway for the installation of a gas vent (Figure 12).Common (combined) venting is allowable with vertical typeB vent systems and lined masonry chimneys as long asproper draft for the water heater is established under allconditions of operation. CAUTION: DO NOT common ventthis water heater with any power vented appliance.Figures 10-12 are examples of vent pipe systeminstallations and may or may not be typical for yourspecific application. Consult the “National Fuel Gas Code”,NFPA 54, ANSI Z223.1-current edition and the guidelinesset forth by prevailing local codes.

Temperature and Pressure Relief Valve1” MINIMUMMETALDRAIN PANDRAINExplosion Harzard• Temperature-pressure reliefvalve must comply with ANSIZ21.22-CSA 4.4 and ASMEcode.• Properly sized temperaturepressurerelief valve must beinstalled in opening provided.• Can result in overheatingand excessive tank pressure.• Can cause serious injury ordeath.TEMPERATURE AND PRESSURE RELIEF (T&P)VALVE (OPTIONAL TOP T&P RELIEFVALVE NOT SHOWN)DISCHARGE PIPEDO NOT CAP OR PLUGDRAIN LINE 3/4”ID MINIMUMFIGURE 15A.6” MAXIMUMAIR GAPFor protection against excessive pressures andtemperatures, a temperature and pressure relief valve mustbe installed in the opening marked “T & P RELIEF VALVE”(see Figure 15A). This valve must be design certified bya nationally recognized testing laboratory that maintainsperiodic inspection of the production of listed equipment ormaterials as meeting the requirements for Relief Valves forHot <strong>Water</strong> Supply Systems, ANSI Z21.22. The function ofthe temperature and pressure relief valve is to dischargewater in large quantities in the event of excessivetemperature or pressure developing in the water heater.The valve’s relief pressure must not exceed the workingpressure of the water heater as stated on the rating plate.IMPORTANT: Only a new temperature and pressure reliefvalve should be used with your water heater. Do not use anold or existing valve as it may be damaged or not adequatefor the working pressure of the new water heater. Do notplace any valve between the relief valve and the tank.The Temperature & Pressure Relief Valve:• Must not be in contact with any electrical part.• Must be connected to an adequate discharge line.• Must not be rated higher than the working pressureshown on the rating plate of the water heater.The Discharge Line:• Must not be smaller than the pipe size of the reliefvalve or have any reducing coupling installed in thedischarge line.• Must not be capped, blocked, plugged or contain anyvalve between the relief valve and the end of the dis-17charge line.• Must terminate a maximum of six inches above a floordrain or external to the building. In cold climates, it isrecommended that the discharge pipe be terminated atan adequate drain inside the building.• Must be capable of withstanding 250°F (121°C) withoutdistortion.• Must be installed to allow complete drainage of boththe valve and discharge line.T&P Relief Valve and Pipe Insulation (Some Models)1. Locate the temperature and pressure relief valve onthe water heater (also known as a T&P relief valve).See Figure 15B.2. Locate the slit running the length of the T&P reliefvalve insulation.3. Spread the slit open and fit the insulation over the T&Prelief valve. See Figure 15B. Apply gentle pressureto the insulation to ensure that it is fully seated on theT&P Relief Valve. Once seated, secure the insulationwith duct tape, electrical tape, or equivalent.IMPORTANT: The insulation or tape should not blockor cover the T&P relief valve drain opening. Also, theinsulation or tape should not block or hinder accessto the manual relief lever (Figure 15B). Ensurethat a discharge pipe is installed into the T&P valvedischarge opening per the instructions in this manual.4. Locate the hot water (outlet) & cold water (inlet) pipesto the water heater.5. Locate the slit running the length of a section of pipeinsulation.6. Spread the slit open and slip the insulation over the coldwater (inlet) pipe. Apply gentle pressure along the lengthof the insulation to ensure that it is fully seated aroundthe pipe. Also, ensure that the base of the insulation isflush with the water heater. Once seated, secure theinsulation with duct tape, electrical tape, or equivalent.7. Repeat steps 5 and 6 for the hot water (outlet) pipe.8. Add additional sections of pipe insulation as needed.MANUAL RELIEFLEVERT&P RELIEFVALVET&P RELIEF VALVEDRAIN LINET&P RELIEF VALVE INSULATIONFIGURE 15B.Combination Space Heating/Potable<strong>Water</strong> SystemSome water heater models are equipped with inlet/outletconnections for use with space heating applications. If thiswater heater is to be used to supply both space heatingand domestic potable (drinking) water, the instructionslisted below must be followed.• Be sure to follow the manual(s) shipped with the airhandler system.

• This water heater is not to be used as a replacementfor an existing boiler installation.• Do not use with piping that has been treated withchromates, boiler seal or other chemicals and do notadd any chemicals to the water heater piping.• If the space heating system requires watertemperatures in excess of 120°F, a mixing valveor an anti-scald device should be installed per itsmanufacturer’s instructions in the domestic (potable)hot water supply to limit the risk of scald injury.• Pumps, valves, piping and fittings must be compatiblewith potable water.• A properly installed flow control valve is required toprevent thermosiphoning. Thermosiphoning is theresult of a continuous flow of water through the airhandler circuit during the off cycle. Weeping (blow off)of the temperature and pressure relief valve (T & P)or higher than normal water temperatures are the firstsigns of thermosiphoning.• The domestic hot water line from the water heatershould be vertical past any mixing valve or supply line tothe air handler to remove air bubbles from the system.Otherwise, these bubbles will be trapped in the airhandler heat exchanger coil, reducing the efficiency.• Do not connect the water heater to any system orcomponents previously used with non-potable waterheating appliances when used to supply potable water.Some jurisdictions may require a backflow preventer in theincoming cold water line. This may cause the temperatureand pressure relief valve on the water heater to dischargeor weep due to expansion of the heated water. Adiaphragm-type expansion tank suitable for potable waterwill normally eliminate this weeping condition. Pleaseread and follow the manufacturer’s instructions for theinstallation of such tanks.Also see <strong>Water</strong> System Piping for additional instructionson the safe and correct installation and operation of thiswater heater.TEMPERINGVALVEDOMSETICHOT WATEROUTHOTWATEROUTUNIONSMUST BE VERTICAL TOREMOVE AIR BUBBLESFLOW CONTROLVALVEPUMPOUTTYPICAL TEMPERING VALVE INSTALLATION COMBINATIONSPACE HEATING/POTABLE WATER HEATING SYSTEMSolar InstallationVACUUMRELIEFVALVETOAIRHANDLERSHUT-OFFVALVEFIGURE 16.EXPANSION TANKCOLD WATER INLETMASSACHUSETTS CODEDOES NOT ALLOW THISTYPE OF INSTALLATION.COILAIRHANDLERIf this water heater is used as a solar storage heateror as a backup for the solar system, the water supplytemperatures to the water heater tank may be in excessof 120°F. A mixing valve or other temperature limitingvalve must be installed in the water supply line to limit thesupply temperature to 120°F.NOTE: Solar water heating systems can often supplywater with temperatures exceeding 180°F and may resultin water heater malfunction.IN18

IMPORTANT INFORMATION ABOUT THIS WATER HEATERThis gas water heater was manufactured to voluntary safety standards to reduce the likelihood of a flammable vaporignition incident. The new technology used in meeting these standards makes this product more sensitive to installationerrors. Please review the following checklist and make any required installation upgrades or changes.Questions? Contact Residential Technical Assistance by referencing the phone number on the front of the InstallationInstructions and Use & Care Guide.Installation Checklist<strong>Water</strong> Heater Location<strong>Water</strong> heater location is important and can affect systemperformance. Please check the following:□ Installation area free of corrosive elements and flammablematerials.□ Centrally located with the water piping system.Located as close to the gas piping and vent pipesystem as possible.□ Located indoors and in a vertical position. Protectedfrom freezing temperatures.□ Proper clearances from combustible surfacesmaintained and not installed directly on a carpetedfloor.□ Provisions made to protect the area from waterdamage. Metal drain pan installed and piped to anadequate drain.□ Sufficient room to service the water heater. See“Clearances and Accessibility” section of thismanual.□ <strong>Water</strong> heater not located near an air moving device.□ Is the installed environment dirty (excessive amountsof lint, dirt, dust, etc.)? If so, the flame arrestorlocated on the bottom of the water heater will need tobe cleaned periodically. Refer to the “Maintenanceof your <strong>Water</strong> Heater” section of this manual forinformation on cleaning the flame arrestor.Combustion Air Supply and VentilationCheck for sufficient combustion air supply. Insufficient airfor the combustion of gas will result in the flame becoming“lazy”, thereby allowing heat to build up in the combustionchamber. This excessive heat will cause a thermal switchon the door assembly to trip. Is the water heater installed ina closet or other small, enclosed space? If so:□ Are there openings for make-up air to enter andexit the room/area?□ Are the openings of sufficient size? Remember,if there are other gas-fired or air-consumingappliances in the same room, you need moremake-up air. Refer to the “Location Requirements”section of this water heater manual for specificrequirements.Fresh air not taken from areas that contain negativepressure producing devices such as exhaust fans,fireplaces, etc.□ Is there a furnace/air handler in the same roomspace as the water heater? If so, has a return airduct system been attached that exits the room?If so, check for leaks on the air duct system. If noair duct system is present, correct immediatelyby contacting a local Heating, Ventilation, Air-Conditioning & Refrigeration (HVAC-R) authorizedservice provider.□ Fresh air supply free of corrosive elements andflammable vapors.□ Fresh air openings sized correctly with considerationgiven to the blocking effect of louvers and grilles.□ Ductwork is the same cross-sectional area as theopenings.Vent Pipe SystemCheck for proper drafting at the water heater draft hood.Refer to the “Checking the Draft” section of this manual forthe test procedure. If the procedure shows insufficient draftis present, please check the following.□ Draft hood properly installed.□ Vent connectors securely fastened with screws andsupported properly to maintain six inch clearance.□ Vent connector made of approved material andsized correctly.□ Vent pipe system installed according to all localand state codes or, in the absence of local andstate codes, the “National Fuel Gas Code”, ANSIZ223.1(NFPA 54)-current edition.□ Flue baffle properly positioned in the flue tube.□ Check the vent system for restrictions/obstructionsand check the vent termination height. Refer to the“Air Supply and Ventilation” section of this waterheater manual for specific requirements.□ Recheck for sufficient combustion air supply.<strong>Water</strong> System Piping□ Temperature and pressure relief valve properlyinstalled with a discharge line run to an open drainand protected from freezing.□ All piping properly installed and free of leaks.□ Heater completely filled with water.□ Closed system pressure build-up devices installed.□ Mixing valve (when applicable) installedper manufacturer’s instructions (see “<strong>Water</strong>Temperature Regulation” section).Gas Supply and Piping□ Gas type is the same as that listed on the waterheater data plate.□ Gas line equipped with shut-off valve, union, anddrip leg.□ Adequate pipe size and approved pipe material.□ An approved noncorrosive leak detection solutionused to check all connections and fittings forpossible gas leaks. If such a solution is notavailable, use a mixture of dish washing soap andwater (one part soap to 15 parts water) or children’ssoap bubble solution. Bubbles forming indicate aleak. Correct any leak found.TEFLON ® is a registered trademark of E.I. Du Pont De Nemours andCompany.19

OPERATING YOUR WATER HEATERLighting InstructionsRead and understand these directions thoroughly beforeattempting to light or re-light the pilot. Make sure the viewport is not missing or damaged. (See Figure 23.) Makesure the tank is completely filled with water before lightingthe pilot. Check the rating plate near the gas control valve/thermostat for the correct type of gas. Do not use thiswater heater with any gas other than the one listed on therating plate. If you have any questions or doubts, consultyour gas supplier or gas utility company.WARNINGExplosion HazardReplace view port if glass is missingor damaged.Failure to do so can result in death,explosion or fire.Lighting the Pilot:1. Read and follow the lighting instructions on the waterheater’s label.2. Turn the Control Knob to Pilot. Press the Knob in fullyand hold it in. (The knob will travel in about 1/4-inch ifit is set to Pilot correctly.)3. Click the Igniter button continuously for up to 90seconds or until the Status Light begins to blink.If the Status Light does not begin to blink after 90seconds, STOP. Wait 10 minutes before attemptingto relight the Pilot. Repeat these steps 2-3 times, ifnecessary.The circuitry in this gas valve requires that you wait 10minutes between lighting attempts.If the Status Light blinks, release the ControlKnob and turn it to the desired setting. (“Hot” isapproximately 120°F).If the Status Light Does Not Blink:1. Wait 10 minutes before another lighting attempt.2. If the Status Light did not blink, repeat the lightingprocedure by following the lighting instructions onthe water heater’s label. Remove the outer door.The Control Knob must be set to Pilot and held incontinuously while clicking the igniter button (aboutonce per second for up to 90 seconds). To observe thePilot, remove the outer door and look through the viewport (sight glass). See Figure 23.3. Continue clicking the Igniter button (for up to 90seconds) until Pilot lights.4. Once the Pilot is lit, continue to hold the Control Knobin until the Status Light begins to blink.5. Release Control Knob and set Knob to desiredtemperature setting. (“Hot” is approximately 120°F.)6. Replace the outer door.If the Pilot Does Not Light:1. Wait 10 minutes before another lighting attempt.If the pilot does not light, the Igniter may not besparking or the unit may not be getting gas (or for anew installation, there may still be air in the gas line).Each time you click the igniter button, you should beable to see the spark by looking through the view port.See Figure 23. (You may have to darken the roomlights to see the spark.) You do not have to push the20Control Knob in to check the Igniter button. Simplylook through the sight glass while clicking the Igniterbutton and look for a spark. If you can’t see a sparkwhen the Igniter button is clicked, check the wiringconnections from the Igniter button and make sure thatthey are tight.2. If you see the Igniter spark, try relighting the pilot byfollowing the instructions on the water heater’s label.Ensure that the gas supply is tuned on. There maybe air in the gas line, and several lighting attemptsmay be needed to completely fill the line with gas andsuccessfully light the pilot.If the Pilot Lights but the Status Light Does Not Blink:1. If the pilot lights, continue to hold the Control Knobin until the Status Light blinks. If the pilot is lit andremains lit for 90 seconds and the Status Light stilldoes not blink, the thermopile connections may beloose, the thermal switch may need to be reset, or thethermopile may be defective.2. Remove the outer door.3. Press the reset button on the thermal switch (Figure 23).4. If switch clicks, it may have tripped. Do not light thePilot if flammable vapors are present. Check flamearrestor for signs of discoloration (which could becaused by flammable vapors). If the flame arrestor isdiscolored, do not attempt to relight the Pilot. Havethe water heater inspected by a qualified servicetechnician.5. Check the wiring connections from the thermopile andthe thermal switch to the gas control valve/thermostat.Ensure that all wiring connections are tight. SeeFigure 23.6. Replace the outer door.7. Wait 10 minutes and try to light the Pilot according tothe instructions on the water heater’s label.8. While clicking the Igniter button continuously,the Control Knob must be set to Pilot and heldin until the Status Light blinks. Once the StatusLight blinks, release the Control Knob and set theKnob to the desired temperature setting. (“Hot” isapproximately 120°F.)

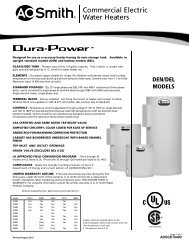

FOR YOUR SAFETY READ BEFORE LIGHTINGGas Control/Temperature KnobWARNING:If you do not follow these instructions exactly, afire or explosion may result causing property damage, personalinjury or loss of life.StatusLightLIGHTING INSTRUCTIONS120°FMarkFIGURE 'A'FIGURE 'B'120°FMark120°FMarkFIGURE 'C'FLAMMABLEBEFORE LIGHTING: ENTIRE SYSTEM MUST BE FILLED WITH WATER AND AIR PURGED FROM ALL LINESA. This appliance has a pilot which is lit by a piezoelectricspark gas ignition system. Do not open knob. Never use tools. If the knob will not push in orC. Use only your hand to push in or turn the gas controlthe inner door of the appliance and try to light turn by hand, don't try to repair it, call a qualifiedthe pilot by hand.service technician. Force or attempted repair mayB.BEFORE LIGHTING smell all around the appliance result in a fire or explosion.area for gas. Be sure to smell next to the floor D. Do not use this appliance if any part has been underbecause some gas is heavier than air and will water. Immediately contact a qualified installer orsettle on the floor.service agency to replace a flooded water heater.WHAT TO DO IF YOU SMELL GASDo not attempt to repair the unit! It must be replaced!Do not try to light any appliance.E. DO NOT USE THIS APPLIANCE IF THERE HASDo not touch any electric switch; do not use any BEEN AN IGNITION OF VAPORS. Immediatelyphone in your building.call a qualified service technician to inspect theImmediately call your gas supplier from a neighbor's appliance. <strong>Water</strong> heaters subjected to aphone. Follow the gas supplier's instructions. flammable vapors ignition will show aIf you cannot reach your gas supplier, call the fire discoloration on the air intake grid and requiredepartment.replacement of the entire water heater.MAIN BURNERTHERMOPILEVACIgniterGAS CONTROL"OFF" POSITION1. STOP! It is imperative that you read all safetywarnings before lighting the pilot."PILOT" POSITION2. Turn the gas control/temperature knobcounterclockwise to the "OFF" setting.3. Wait ten (10) minutes to clear out any gas. If you thensmell gas, STOP! Follow “ B” in the safetyinformation above on this label. If you do notsmell gas, go to the next step.4. Turn the gas control/temperature knob clockwise to“ PILOT”. See Figure ‘B’.5. Press the gas control/temperature knob all the wayin and hold it in. The knob should travel in about1/4 inch (6.35 mm) if it is set to "PILOT" correctly.While holding the gas control/temperature knob in,click the igniter button continuously (about once asecond) for up to 90 seconds or until Status Lightbegins to blink.6. When the status light starts blinking, release thegas control/temperature knob. Set the gas control/"ON" POSITIONCONTROL KNOBPILOTFIGURE 'D'temperature knob to the desired setting. See Figure ‘C’.If the status light does not start blinking within 90seconds, repeat steps 2 through 5 up to THREE (3)times, waiting 10 minutes between lighting attempts.The circuitry in this advanced gas valve requiresthat you wait 10 minutes between lighting attempts.If the status light turns solid red, release the gascontrol/temperature knob and repeat steps 2 through 5(waiting 10 minutes before attempting to relight the pilot).If the status light does not start blinking after threelighting attempts, turn the gas control/temperature knobto "OFF" and call a qualified service technician or yourgas supplier.DANGER: Hotter water increases the risk of scaldinjury. Consult the instruction manual beforechanging temperature.Refer to the Lighting Instructions in the InstallationManual for more detailed troubleshootinginformation.TO TURN OFF GAS TO APPLIANCE1. Turn the gas control/temperature knob counterclockwise to the "OFF" setting. The status light will stop blinking and stayon for a short time after the water heater is turned off. See Figure ‘A’.21

Checking the Draft<strong>Water</strong> Temperature RegulationDo not touch vent.WARNINGBurn HazardDoing so can result in burns.After successfully lighting the water heater, allow the unit tooperate for 15 minutes and check the draft hood reliefopening for proper draft (Figure 17). Make sure all otherappliances in the area are operating and all doors are closedwhen performing the draft test. Pass a match flame aroundthe relief opening of the draft hood. A steady flame drawninto the opening indicates proper draft.MATCHDRAFT HOODRELIEFOPENINGFIGURE 17.If the flame flutters or is blown out, combustion products areescaping from the relief opening. If this occurs, do not operatethe water heater until proper adjustments or repairs are madeto the vent pipe system and/or air supply requirements.Burner FlamesInspect the burner flames through the viewport andcompare them to the drawings in Figure 18. A properlyoperating burner should produce a soft blue flame. Bluetips with yellow inner cones are satisfactory. The tipsof the flame may have a slight yellow tint. The flameshould not be all yellow or have a sharp blue-orangecolor. Contaminated air may cause an orange coloredflame. Contact a qualified technician if the flame is notsatisfactory.Emergency Shut DownFIGURE 18.IMPORTANT: Should overheating occur or the gas supplyfails to shut off, turn off the water heater’s manual gascontrol valve and call a qualified technician.<strong>Water</strong> temperature over 125°F (52°C)can cause servere burns instantlyresulting in severe injury or death.Children, the elderly, and thephysically or mentally disabled are athighest risk for scald injury.Feel water before bathing orshowering.Temperature limiting valves areavailable.Read instruction manual for safetemperature setting.Due to the nature of the typical gas water heater, the watertemperature in certain situations may vary up to 30°F(16.7 °C) higher or lower at the point of use such as,bathtubs, showers, sink, etc.HOTTER WATER CAN SCALD: <strong>Water</strong> heaters areintended to produce hot water. <strong>Water</strong> heated to atemperature which will satisfy space heating, clotheswashing, dish washing, and other sanitizing needs canscald and permanently injure you upon contact. Somepeople are more likely to be permanently injured by hotwater than others. These include the elderly, children,the infirm, or physically/mentally handicapped. If anyoneusing hot water in your home fits into one of these groupsor if there is a local code or state law requiring a certaintemperature water at the hot water tap, then you musttake special precautions. In addition to using the lowestpossible temperature setting that satisfies your hot waterneeds, a means such as a mixing valve should be usedat the hot water taps used by these people or at the waterheater. Mixing valves are available at plumbing supply orhardware stores. See Figure 14. Follow manufacturer’sinstructions for installation of the valves. Before changingthe factory setting on the thermostat, see Figure 19A.Using the lowest hot water temperature that meets yourneeds will also provide the most energy efficient operationof the water heater.Never allow small children to use a hot water tap, orto draw their own bath water. Never leave a child orhandicapped person unattended in a bathtub or shower.NOTE: A water temperature range of 120°F-140°F(49°C-60°C) is recommended by most dishwashermanufacturers.The thermostat is adjusted to the pilot position when itis shipped from the factory. <strong>Water</strong> temperature can beregulated by moving the temperature dial to the preferredsetting. The preferred starting point is 120°F at the “HOT”setting. Align the knob with the desired water temperatureas shown in Figure 19A. There is a hot water scaldpotential if the thermostat is set too high.NOTE: Temperatures shown on the gas control valve/thermostat are approximates. The actual temperature ofthe heated water may vary.IMPORTANT: Adjusting the thermostat past the 120°Fmark on the temperature dial will increase the risk of scaldinjury. Hot water can produce first degree burns within:22

<strong>Water</strong>Temperature °F110116116122131140149154Time for 1stDegree Burn(Less Severe Burns)(normal shower temp.)(pain threshold)35 minutes1 minute5 seconds2 seconds1 secondInstantaneousTime forPermanent Burns2nd & 3rd Degree(Most Severe Burns)45 minutes5 minutes25 seconds5 seconds2 seconds1 second(U.S. Government Memorandum, C.P.S.C., Peter L. Armstrong, Sept. 15,1978)GAS CONTROL VALVE/THERMOSTATSETTINGSGAS CONTROL/TEMPERATURE KNOBSTATUSLIGHT120°FMARK<strong>Water</strong> Temperature AdjustmentThe water temperature setting can be adjusted from 55°Fto 155°F. Turn the Gas Control/Temperature Knob to thedesired setting/temperature.NOTE:• Some models are certified for 180°F outlettemperatures. See the Data Plate on the front of thewater heater for the maximum outlet temperature.• The temperatures indicated are approximates. Theactual temperature of the heated water may vary.Operating Modes and Settings• Standard Mode - The controller adjusts the waterheater to maintain the temperature set by the user.• Vacation Setting - The Vacation setting (VAC) setsthe controller at approximately 55°F. This setting isrecommended when the water heater is not in use for along period of time. This effectively turns the controllertemperature setting down to a temperature thatprevents the water in the water heater from freezingwhile still conserving energy.VACIGNITERFIGURE 19A.Should overheating occur or the gas supply fail to shut off,turn off the manual gas control valve to the appliance.NOTE: During low demand periods when hot water is notbeing used, a lower thermostat setting will reduce energylosses and may satisfy your normal hot water needs. If hotwater use is expected to be more than normal, a higherthermostat setting may be required to meet the increaseddemand. When leaving your home for extended periods(vacations, etc.) turn the temperature dial to its lowestsetting. This will maintain the water at low temperatureswith minimum energy losses and prevent the tank fromfreezing during cold weather.Operating the Temperature Control SystemList of status codes are shownat top of gas control valve/thermostat.VACFIGURE 19B.23Status Light CodeNormal Flashes:• 0 Flashes Indicates Control Off/Pilot Out.• 1 Flash Indicates Normal Operation.• A solid red light indicates that the gas controlvalve/thermostat is shutting down.Diagnostic Flashes:If the water heater is not working, look for the followingdiagnostic flashes after lighting the pilot. For more details, see“Status Light and Diagnostic Code Troubleshooting Chart.”2 Flashes Indicates Thermopile Voltage Low4 Flashes Indicates Overheat Failure5 Flashes Indicates Sensor Failure7 Flashes Indicates Electronic Control Failure8 Flashes See “Status Light and Diagnostic CodeTroubleshooting Chart.”Operational ConditionsCondensationWhenever the water heater is filled with cold water, somecondensate will form while the burner is on. A waterheater may appear to be leaking when in fact the water iscondensation. This usually happens when:a. A new water heater is filled with cold water for the first time.b. Burning gas produces water vapor in water heaters, particularlyhigh efficiency models where flue temperaturesare lower.c. Large amounts of hot water are used in a short time andthe refill water in the tank is very cold.Moisture from the products of combustion condense on thecooler tank surfaces and form drops of water which may fallonto the burner or other hot surfaces to produce a “sizzling”or “frying” noise.