OneSteel Solutions 6.pdf

OneSteel Solutions 6.pdf

OneSteel Solutions 6.pdf

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

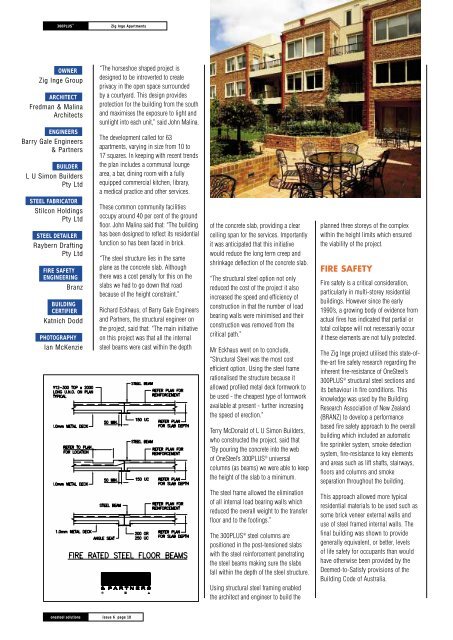

300PLUS ®Zig Inge ApartmentsOWNERZig Inge GroupARCHITECTFredman & MalinaArchitects“The horseshoe shaped project isdesigned to be introverted to createprivacy in the open space surroundedby a courtyard. This design providesprotection for the building from the southand maximises the exposure to light andsunlight into each unit,” said John Malina.ENGINEERSBarry Gale Engineers& PartnersBUILDERL U Simon BuildersPty LtdThe development called for 63apartments, varying in size from 10 to17 squares. In keeping with recent trendsthe plan includes a communal loungearea, a bar, dining room with a fullyequipped commercial kitchen, library,a medical practice and other services.STEEL FABRICATORStilcon HoldingsPty LtdSTEEL DETAILERRaybern DraftingPty LtdFIRE SAFETYENGINEERINGBranzBUILDINGCERTIFIERKatnich DoddPHOTOGRAPHYIan McKenzieThese common community facilitiesoccupy around 40 per cent of the groundfloor. John Malina said that: “The buildinghas been designed to reflect its residentialfunction so has been faced in brick.“The steel structure lies in the sameplane as the concrete slab. Althoughthere was a cost penalty for this on theslabs we had to go down that roadbecause of the height constraint.”Richard Eckhaus, of Barry Gale Engineersand Partners, the structural engineer onthe project, said that: “The main initiativeon this project was that all the internalsteel beams were cast within the depthof the concrete slab, providing a clearceiling span for the services. Importantlyit was anticipated that this initiativewould reduce the long term creep andshrinkage deflection of the concrete slab.“The structural steel option not onlyreduced the cost of the project it alsoincreased the speed and efficiency ofconstruction in that the number of loadbearing walls were minimised and theirconstruction was removed from thecritical path.”Mr Eckhaus went on to conclude,“Structural Steel was the most costefficient option. Using the steel framerationalised the structure because itallowed profiled metal deck formwork tobe used - the cheapest type of formworkavailable at present - further increasingthe speed of erection.”Terry McDonald of L U Simon Builders,who constructed the project, said that“By pouring the concrete into the webof <strong>OneSteel</strong>’s 300PLUS ® universalcolumns (as beams) we were able to keepthe height of the slab to a minimum.planned three storeys of the complexwithin the height limits which ensuredthe viability of the project.FIRE SAFETYFire safety is a critical consideration,particularly in multi-storey residentialbuildings. However since the early1990’s, a growing body of evidence fromactual fires has indicated that partial ortotal collapse will not necessarily occurif these elements are not fully protected.The Zig Inge project utilised this state-ofthe-artfire safety research regarding theinherent fire-resistance of <strong>OneSteel</strong>’s300PLUS ® structural steel sections andits behaviour in fire conditions. Thisknowledge was used by the BuildingResearch Association of New Zealand(BRANZ) to develop a performancebased fire safety approach to the overallbuilding which included an automaticfire sprinkler system, smoke detectionsystem, fire-resistance to key elementsand areas such as lift shafts, stairways,floors and columns and smokeseparation throughout the building.The steel frame allowed the eliminationof all internal load bearing walls whichreduced the overall weight to the transferfloor and to the footings.”The 300PLUS ® steel columns arepositioned in the post-tensioned slabswith the steel reinforcement penetratingthe steel beams making sure the slabsfall within the depth of the steel structure.Using structural steel framing enabledthe architect and engineer to build theThis approach allowed more typicalresidential materials to be used such assome brick veneer external walls anduse of steel framed internal walls. Thefinal building was shown to providegenerally equivalent, or better, levelsof life safety for occupants than wouldhave otherwise been provided by theDeemed-to-Satisfy provisions of theBuilding Code of Australia.onesteel solutions issue 6 page 18