Instruction Manual book - Pichler

Instruction Manual book - Pichler

Instruction Manual book - Pichler

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

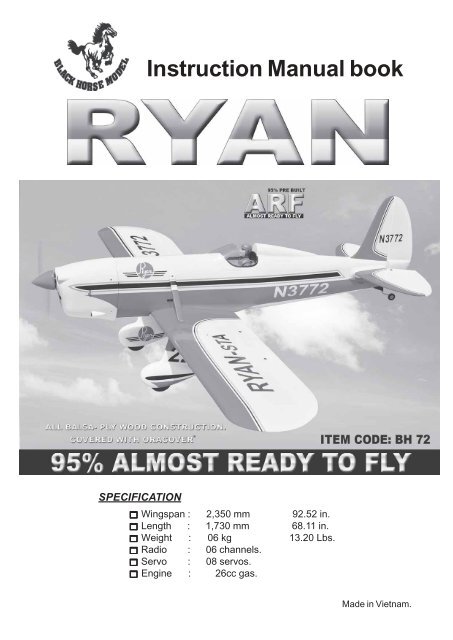

<strong>Instruction</strong> <strong>Manual</strong> <strong>book</strong>SPECIFICATION Wingspan : 2,350 mm 92.52 in. Length : 1,730 mm 68.11 in. Weight : 06 kg 13.20 Lbs. Radio : 06 channels. Servo : 08 servos. Engine : 26cc gas.Made in Vietnam.

RYAN - Item code: BH72 .<strong>Instruction</strong> <strong>Manual</strong>This instruction manual is designed to help you build a great flying aeroplane. Please read thismanual thoroughly before starting assembly of your RYAN. Use the parts listing below to identify allparts.WARNING.Please be aware that this aeroplane is not a toy and if assembled or used incorrectly it iscapable of causing injury to people or property. WHEN YOU FLY THIS AEROPLANE YOUASSUME ALL RISK & RESPONSIBILITY.If you are inexperienced with basic R/C flight we strongly recommend you contact your R/C supplierand join your local R/C Model Flying Club. R/C Model Flying Clubs offer a variety of trainingprocedures designed to help the new pilot on his way to successful R/C flight. They will also be ableto advise on any insurance and safety regulations that may apply.TOOLS & SUPPLIES NEEDED.Thick cyanoacrylate glue.30 minute epoxy.5 minute epoxy.Hand or electric drill.Assorted drill bits.Modelling knife.Straight edge ruler.2mm ball driver.Phillips head screwdriver.220 grit sandpaper.90° square or builder’s triangle.Wire cutters.Masking tape & T-pins.Thread-lock.Paper towels.PARTS LISTING.FUSELAGE ASSEMBLY (1) Fuselage.WING ASSEMBLY(1) Right wing half with pre-installedaileron.(1) Left wing half with pre-installedaileron.Tail section assembly(1) Vertical stabilizer with preinstalledrudder.(1) Horizontal stabilizer with preinstalledelevator halves.Some more parts.HARDWARE PACKCOWLING.Landing gear.....SUGGESTION.To avoid scratching your new airplane, do notunwrap the pieces until they are needed forassembly. Cover your workbench with an oldtowel or brown paper, both to protect the aircraftand to protect the table. Keep a couple ofjars or bowls handy to hold the small parts afteryou open the bag.NOTE.Please trial fit all the parts. Make sure you havethe correct parts and that they fit and arealigned properly before gluing! This will assureproper assembly. RYAN ARF is hand madefrom natural materials, every plane is uniqueand minor adjustments may have to be made.However, you should find the fit superior andassembly simple.The painted and plastic parts used in this kitare fuel proof. However, they are not tolerantof many harsh chemicals including the following:paint thinner, C/A glue accelerator, C/A gluedebonder and acetone. Do not let these chemicalscome in contact with the colors on thecovering and the plastic parts.2

RYAN - Item code: BH72.INSTRUCTION MANUALSAFETY PRECAUTION.+ This is not a toy+ Be sure that no other flyers are using yourradio frequency.+ Do not smoke near fuel+ Store fuel in a cool, dry place, away fromchildren and pets.+ Wear safety glasses.+The glow plug clip must be securely attachedto the glow plug.+ Do not flip the propeller with your fingers.+ Keep loose clothing and wires away fromthe propeller.+ Do not start the engine if people are near.Do not stand in line with the side of the propeller.+ Make engine adjustments from behind thepropeller only. Do not reach around the spinningpropeller.REPLACEMENT LARGE PARTS1.2.3.5.6.8. 4.13.9.12.10.7.11.14.11.I. AILERON.1.INSTALLING THE AILERON SERVOS.E.C.D.F. 1) Install the rubber grommets and brasseyelets onto the aileron servos.B. B.A.G.A. Cowling.C. Fuselage.E. Vertical stabilizer.B. Wing panel.D . Horizon stabilizer.F. Aluminium wing dihedral brace.G. Decal sheet.REPLACEMENT SMALL PARTS1. Under carriage struts.2. Oleo strut.3. Plastic - enginemount.4. Plastic parts for horizon stabilizer.5. Plastic top fuselage.6. Fuel tank.7. Wing struts.8. Wheels9. Spinner.10. Tail gear set.11. Wheel spat.12. Plastic fairing.13. Plastic for pushrod.14. Rudder push-pull cable.FlapAileronAileronBottom sideC/A glueBottom side3

RYAN - Item code: BH72 .<strong>Instruction</strong> <strong>Manual</strong>C/A glueC/A glueBottom sideBottom sideC/A glueC/A glueBottom sideBottom sideBottom sideC/A glueBottom sideBottom side 2) Using a modeling knife, remove the coveringat possition show below.RemovecoveringC/A glueBottom side4

RYAN - Item code: BH72.INSTRUCTION MANUALSecureSecure 3) Using the thread as a guide and usingmasking tape, tape the servo lead to the endof the thread: carefully pull the thread out.When you have pulled the servo lead out, removethe masking tape and the servo leadfrom the thread.Bottom side 4) Drill 1,6mm pilot holes through the blockof wood for each of the four mounting screwsprovided with the servo. 5. Instal servo tray with aileron servo intothe wing as same as picture below.Electric wireBottom side2.INSTALLING THE AILERON CONTROL HORN.3mm x 40mm.threadM3 lock nut.Nilon control clasp.2x10mm.5

RYAN - Item code: BH72 .<strong>Instruction</strong> <strong>Manual</strong>Aileron control hornRemove coveringBottom sideRepeat the procedure for the other winghalf.3.INSTALLING THE AILERONLINKAGES.Installing the aileron linkages as picturesbelow.M3M3 lock nut6

RYAN - Item code: BH72.INSTRUCTION MANUAL2x10mm.C/A glue.II. FLAP.1.INSTALLING THE FLAP SERVOS.Flap2.INSTALLING THE FLAP CONTROL HORN.ThreadRemovecoveringElectric wire.3mm x 40mm.M3 lock nut.Nilon control clasp.7

RYAN - Item code: BH72 .<strong>Instruction</strong> <strong>Manual</strong>Flap controlhorn.3. INSTALLING THE FLAPLINKAGES.Installing the aileron linkages as picturesbelow.M3M3 lock nutC/A glue.FlapAileronRepeat the procedure for the other winghalf.8

RYAN - Item code: BH72.INSTRUCTION MANUALMAIN GEAR INSTALATION.PARTS REQUIRED11.Mark point12.8.3 x 10mm2.3 x 15mm3 x 15mm1.SecureRemove covering3 x 15mmMark pointSecure9

RYAN - Item code: BH72 .<strong>Instruction</strong> <strong>Manual</strong>CutMark point10

RYAN - Item code: BH72.INSTRUCTION MANUAL3x 15mmSecureC/A glue.Secure11

RYAN - Item code: BH72 .<strong>Instruction</strong> <strong>Manual</strong>4x 35mmDrill a hole 3mmdiameter.brace.WING ATTACHMENT.Locate the aluminium wing dihedralSecure*** Test fit the aluminium tube dihedral braceinto each wing haft. The brace should slide ineasily. If not, use 220 grit sand around theedges and ends of the brace until it fits properly.Remove covering12

RYAN - Item code: BH72.INSTRUCTION MANUALINSTALLING THE ENGINE MOUNT.See pictures below:4x 30mm4x 30mmFUEL TANK.INSTALLING THE STOPPER ASSEMBLY 1) The stopper has been pre-assembledat the factory. 2) Using a modeling knife, cut one lengthof silicon fuel line (the length of silicon fuel lineis calculated by how the weighted clunk shouldrest about 8mm away from the rear of the tankand move freely inside the tank). Connect oneend of the line to the weighted clunk and theother end to the nylon pick up tube in the stopper.Drill a hole6mm diameter. 3) Carefully bend the second nylon tubeup at a 45 degree angle (using a cigarettelighter). This tube will be the vent tube to themuffler. 4) Carefully bend the third nylon tube downat a 45 degree angle (using a cigarette lighter).This tube will be vent tube to the fueling valve.When the stopper assembly is installed in thetank, the top of the vent tube should rest justbelow the top surface of the tank. It should nottouch the top of the tank.13

RYAN - Item code: BH72 .<strong>Instruction</strong> <strong>Manual</strong>Blow through one of the lines to ensurethe fuel lines have not become kinked insidethe fuel tank compartment. Air should flowthrough easily. 9) To secure the fuel tank in place, apply abead of silicon sealer to the forward area ofthe tank, where it exits the fuselage behind theengine mounting box and to the rear of the tankat the forward bulkhead.Do not secure the tank into place permanentlyuntil after balancing the airplane. Youmay need to remove the tank to mount thebattery in the fuel tank compartmentVent tubeFuel pick- up tubeFuel fill tube 5) Test fit the stopper assembly into thetank. It may be necessary to remove some ofthe flashing around the tank opening usinga modeling knife. If flashing is present, makesure none of it falls into the tank. 6) When satisfied with the alignment ofthe stopper assembly tighten the 3mm x 20mmmachine screw until the rubber stopper expandsand seals the tank opening. Do not overtighten the assembly as this could cause thetank to split. 7) Using a modeling knife, cut 3 lengths offuel line 150mm long. Connect 2 lines to the 2vent tubes and 1 line to the fuel pickup tube inthe stopper. 8) Feed three lines through the fuel tankcompartment and through the pre-drilled holein the firewall. Pull the lines out from behindthe engine, while guiding the fuel tank intoplace. Push the fuel tank as far forward aspossible, the front of the tank should just abouttouch the back of the firewall.Fuel tank14

RYAN - Item code: BH72.INSTRUCTION MANUALDrill a hole 4mmdiameter.Secure155mmFuel tank15

RYAN - Item code: BH72 .<strong>Instruction</strong> <strong>Manual</strong>After installing the adjustable metal connectorapply a small drop of thin C/A tothe bottom nut. This will prevent the connectorfrom loosening during flight.Connector.Servo arm.Right sideThrottle servoLeft sidePushrod wireThrottle pushrodCOWLING.Pushrod wireINSTALLING THE THROTTLE PUSHROD. Install one adjustable metal connectorthrough the third hole out from the center ofone servo arm, enlarge the hole in the servoarm using a 2mm drill bit to accommodate theservo connector. Remove the excess materialfrom the arm. 1. Slide the fiberglass cowl over the engineand line up the back edge of the cowl withthe marks you made on the fuselage.16

RYAN - Item code: BH72.INSTRUCTION MANUAL 2. While keeping the back edge of thecowl flush with the marks, align the front ofthe cowl with the crankshaft of the engine. Thefront of the cowl should be positioned so thecrankshaft is in nearly the middle of the cowlopening. Hold the cowl firmly in place usingpieces of masking tape. 3. Slide the cowl back over the engineand secure it in place using four wood screws.See picture below. 4. Install the muffler and muffler extensiononto the engine and make the cutout in thecowl for muffler clearance. Connect the fueland pressure lines to the carburetor, mufflerand fuel filler valve.Left sideRight side3 x 12mmTrim and cut afterLeft sideMachine screw.Right side.INSTALLING THE SPINNER.Install the spinner backplate, propeller andspinner cone. The spinner cone is held inplace using two 3mm x 12mm wood screws.3 x 12mmLeft side.17

RYAN - Item code: BH72 .<strong>Instruction</strong> <strong>Manual</strong>SecureC/A glueELEVATOR INSTALLATION. 1. Install the rubber grommets and brasscollets into the elevator servo. Test fit the servointo the servo tray. 2. Mount the servo to the tray using themounting screws provided with your radio system.C/A glue18

RYAN - Item code: BH72.INSTRUCTION MANUALC/A glue 3. Remove the stabilizer. Using the linesyou just drew as a guide, carefully removethe covering from between them using amodeling knife.When cutting through the covering toremove it, cut with only enough pressureto only cut through the covering it’s self.Cutting into the balsa structure mayweaken it. This could lead to possible failureduring flightHORIZONTAL STABILIZER, VESTICALINSTALLATION. Horizontal stabilize installation .See picture below. 1. Draw a center line onto the horizontalstabilizer. Then put the horizontal into the fuselarge.Remove covering.Center line 4. Using a modeling knife, cut away thecovering from the fuselage for the stabilizerand remove it. 2. Mark the shape of the vertical on the leftand right sides onto the horizontal stabilizerusing a felt-tip penCheck to mark sure the wing and stabilizerare paralell. If they are not, lightly sandthe opening in the fuselage for the stabilizeruntil the stabilizer is paralell to the wing.C/A glue.19

RYAN - Item code: BH72 .<strong>Instruction</strong> <strong>Manual</strong> 5. When you are sure that everything isaligned correctly, mix up a generous amountof 30 minute epoxy. Apply a thin layer to thetop and bottom of the stabilizer mounting areaand to the stabilizer mounting platform sidesin the fuselage. Slide the stabilizer in placeand re-align. Double check all of your measurementsone more time before the epoxycures. Remove any excess epoxy using apaper towel and rubbing alcohol and hold thestabilizer in place with T-pins or masking tape. Vestical installation .See picture below.Epoxy glueC/A glueC/A glueEpoxy glue 6. After the epoxy has fully cured, removethe masking tape or T-pins used to hold thestabilizer in place and carefully inspect theglue joints. Use more epoxy to fill in anygaps that were not filled previously andclean up the excess using a paper towel andrubbing alcohol.Epoxy glue20

RYAN - Item code: BH72.INSTRUCTION MANUAL 1. Put the rudder into the fuselage assame as picture below.Remove covering 2. Mark the shape of the vertical on theleft and right side of the rudder on to the horizontalstabilizer using a felt-tip pen.Mark point 5. Put the vertical stabilizer back inplace. Using a triangle, check to ensurethat the vertical stabilizer is aligned 90 degreeto the horizontal stabilizer. 3. Now, remove the rudder and using amodeling knife, carefully cut just inside themarked lines and remove the film of the rudder.Just as you did with the horizontal stabilizer,make sure you only press hard enoughto cut the film, not the balsa rudder.Epoxy glueEpoxy glueRemove covering Also carefully remove the covering fromthe horizontal fin as below the lines whichyou drew as same picture below.21

RYAN - Item code: BH72 .<strong>Instruction</strong> <strong>Manual</strong> 6) When you are sure that everything is aaligned correctly, mix up a generous amountof 30 minute epoxy. Apply a thin layer to theslot in the mounting platform and to the verticalstabilizer mounting area. Apply epoxy tothe lower rudder hinge. Set the stabilizer inplace and re-align. Double check all of yourmeasurements once more before the epoxycures. Remove any excess epoxy using apaper towel and rubbing alcohol and hold thestabilizer in place with T-pins or masking tape.Allow the epoxy to fully cure before proceeding.C/A glueEpoxy glueC/A glueEpoxy glueEpoxy glueC/A glue.22

RYAN - Item code: BH72.INSTRUCTION MANUALC/A glue.C/A glue.Control horn of AileronRemove coveringBottom sideINSTALLING THE ELEVATOR CONTROL HORN.Nilon control clasp.M3 lock nut.3 x 40mm.23

RYAN - Item code: BH72 .<strong>Instruction</strong> <strong>Manual</strong>ELEVATOR AND RUDDER PUSHRODINSTALLATION.Elevator and rudder pushrod install as sameas the way of aileron pushrod.Remove coveringM2M2 lock nut.Elevatorcontrol hornElevatorcontrol horn.Elevatorcontrol horn.ElevatorpushrodElevatorpushrodBottom side24

RYAN - Item code: BH72.INSTRUCTION MANUALRemove coveringTop sideC/A glue.C/A glue.Rudder Control horn.3 x 80mm. Using a modeling knife cut away the coveringfrom the end of fuselage for the rudderhinge.Nilon control clasp.M3 lock nut.25

RYAN - Item code: BH72 .<strong>Instruction</strong> <strong>Manual</strong>C/A glueControl horn of Rudder.Remove covering 1. Rudder pushrod install as same asthe way of aileron control horn. 2. Rudder push - pull system install assame as picture below.M3 clevis ( 4pcs for push - pull system ).M3 lock nut.Rudder push-pull system install as samsas picture belowElevatorpushrodElevatorpushrodRudder cableRudder cable26

RYAN - Item code: BH72.INSTRUCTION MANUALC/A glueRudder push- pull cable.C/A glueCutElevator servoMOUNTING THE TAIL WHEELBRACKET.Rudderservo3x12mmElevator servo 1. Set the tail wheel assembly in placeon the plywood plate. The pivot point of thetail wheel wire should be even with the rudderhinge line and the tail wheel bracketshould be centered on the plywood plate. 2. Using a pen, mark the locations of thetwo mounting screws. Remove the tail wheelbracket and drill 1mm pilot holes at the locationsmarked.27

RYAN - Item code: BH72 .<strong>Instruction</strong> <strong>Manual</strong> 3. Secure the tail wheel bracket in placeusing three 3mm x 12mm wood screws. Becareful not to overtighten the screws.Mark pointINSTALLING THE SWITCH. 1. Cut out the switch hole using amodeling knife. Use a 2mm drill bit and drillout the two mounting holes through the fuselageside. 2. Secure the switch in place using thetwo machine screws provided with the radiosystem.switchINSTALLING THE RECEIVER AND BATTERY.Secure 1. Plug the servo leads and the switchlead into the receiver. You may want toplug an aileron extension into the receiverto makeplugging in the aileron servo lead easierwhen you are installing the wing . Plug thebattery pack lead into the switch. 2. Wrap the receiver and battery pack inthe protective foam to protect them from vibration.Use a rubber band or masking tapeto hold the foam in place. 3. Position the battery pack and receiverbehind the fuel tank. Use two tie wraps tohold the battery and receiver securely in place.As pictures below.Do not permanently secure the receiverand battery until after balancing the model. 4. Using a 2mm drill bit, drill a hole throughthe side of the fuselage, near the receiver,for the antenna to exit.28

RYAN - Item code: BH72.INSTRUCTION MANUALTie wrap.Tie wrap for battery.ReceiverRemove coveringBatteryTie wrapfor receiver6 x 40mmMetal wing bolt.29

RYAN - Item code: BH72 .<strong>Instruction</strong> <strong>Manual</strong>Secure the wing and fuselarge through wingbolt as picture below.3 x 15mmSecureSecureRemove coveringRemove covering30

RYAN - Item code: BH72.INSTRUCTION MANUALCutMark pointRemove coveringC/A glue31

RYAN - Item code: BH72 .<strong>Instruction</strong> <strong>Manual</strong>BALANCING. 1) It is critical that your airplane be balancedcorrectly. Improper balance will causeyour plane to lose control and crash.THE CENTER OF GRAVITY IS LOCATED100MM BACK FROM THE LEADING EDGEOF THE WING. 2) Mount the wing to the fuselage. Using acouple of pieces of masking tape, place themon the top side of the wing 100mm back fromthe leading edge, at the fuselage sides. 3. Turn the airplane upside down. Placeyour fingers on the masking tape and carefullylift the plane .Accurately mark the balance point on the topof the wing on both sides of the fuselage. Thebalance point is located 100mm back fromthe leading edge. This is the balance point atwhich your model should balance for your firstflights. Later, you may wish to experiment byshifting the balance up to 10mm forward orback to change the flying characteristics.Moving the balance forward may improve thesmoothness and arrow- like tracking, but itmay then require more speed for take offand make it more difficult to slow down forlanding. Moving the balance aft makes themodel more agile with a lighter and snappier”feel”. In any case, please start at the locationwe recommend .With the wing attached to the fuselage, allparts of the model installed ( ready to fly), andempty fuel tanks, hold the model at themarked balance point with the stabilizer level.Lift the model. If the tail drops when youlift, the model is “tail heavy” and you mustadd weigh* to the nose. If the nose drops, itis “nose heavy” and you must add weight* tothe tail to balance.*If possible, first attempt to balance the modelby changing the position of the receiver batteryand receiver. If you are unable to obtaingood balance by doing so, then it will be necessaryto add weight to the nose or tail toachieve the proper balance point.CONTROL THROWS. 1) We highly recommend setting up aplane using the control throws listed. 2) The control throws should be measuredat the widest point of each control surface. 3) Check to be sure the control surfacesmove in the correct directions.Ailerons : 15mm up 15mm downElevator : 12mm up 12mm downRudder : 30mm right 30mm leftAilerons ControlPRE-FLIGHT CHECK.151512123030 1) Completely charge your transmitter andreceiver batteries before your first day of flying. 2) Check every bolt and every glue joint inyour plane to ensure that everything is tightand well bonded. 3) Double check the balance of theairplane. 4) Check the control surface. 5) Check the receiver antenna . It shouldbe fully extended and not coiled up inside thefuselage. 6) Properly balance the propeller.We wish you many safe and enjoyableflights with your RYAN.32