TECHNICAL MANUAL - Sharq.biz

TECHNICAL MANUAL - Sharq.biz

TECHNICAL MANUAL - Sharq.biz

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

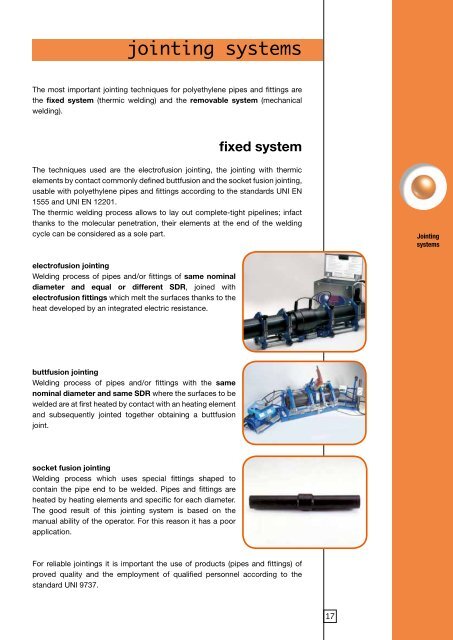

jointing systemsThe most important jointing techniques for polyethylene pipes and fittings arethe fixed system (thermic welding) and the removable system (mechanicalwelding).fixed systemThe techniques used are the electrofusion jointing, the jointing with thermicelements by contact commonly defined buttfusion and the socket fusion jointing,usable with polyethylene pipes and fittings according to the standards UNI EN1555 and UNI EN 12201.The thermic welding process allows to lay out complete-tight pipelines; infactthanks to the molecular penetration, their elements at the end of the weldingcycle can be considered as a sole part.Jointingsystemselectrofusion jointingWelding process of pipes and/or fittings of same nominaldiameter and equal or different SDR, joined withelectrofusion fittings which melt the surfaces thanks to theheat developed by an integrated electric resistance.buttfusion jointingWelding process of pipes and/or fittings with the samenominal diameter and same SDR where the surfaces to bewelded are at first heated by contact with an heating elementand subsequently jointed together obtaining a buttfusionjoint.socket fusion jointingWelding process which uses special fittings shaped tocontain the pipe end to be welded. Pipes and fittings areheated by heating elements and specific for each diameter.The good result of this jointing system is based on themanual ability of the operator. For this reason it has a poorapplication.For reliable jointings it is important the use of products (pipes and fittings) ofproved quality and the employment of qualified personnel according to thestandard UNI 9737.17