TECHNICAL MANUAL - Sharq.biz

TECHNICAL MANUAL - Sharq.biz

TECHNICAL MANUAL - Sharq.biz

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

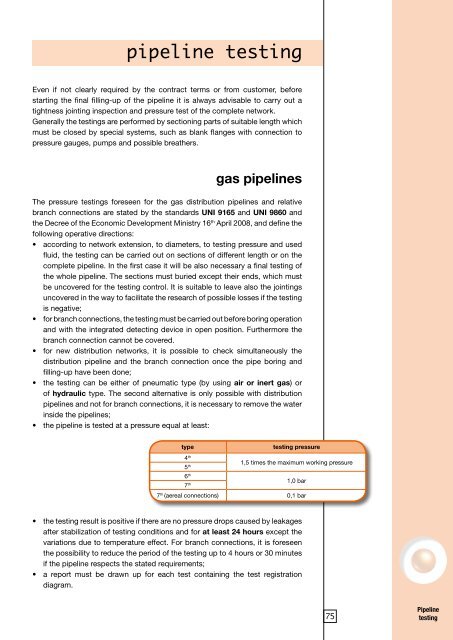

pipeline testingEven if not clearly required by the contract terms or from customer, beforestarting the final filling-up of the pipeline it is always advisable to carry out atightness jointing inspection and pressure test of the complete network.Generally the testings are performed by sectioning parts of suitable length whichmust be closed by special systems, such as blank flanges with connection topressure gauges, pumps and possible breathers.gas pipelinesThe pressure testings foreseen for the gas distribution pipelines and relativebranch connections are stated by the standards UNI 9165 and UNI 9860 andthe Decree of the Economic Development Ministry 16 th April 2008, and define thefollowing operative directions:• according to network extension, to diameters, to testing pressure and usedfluid, the testing can be carried out on sections of different length or on thecomplete pipeline. In the first case it will be also necessary a final testing ofthe whole pipeline. The sections must buried except their ends, which mustbe uncovered for the testing control. It is suitable to leave also the jointingsuncovered in the way to facilitate the research of possible losses if the testingis negative;• for branch connections, the testing must be carried out before boring operationand with the integrated detecting device in open position. Furthermore thebranch connection cannot be covered.• for new distribution networks, it is possible to check simultaneously thedistribution pipeline and the branch connection once the pipe boring andfilling-up have been done;• the testing can be either of pneumatic type (by using air or inert gas) orof hydraulic type. The second alternative is only possible with distributionpipelines and not for branch connections, it is necessary to remove the waterinside the pipelines;• the pipeline is tested at a pressure equal at least:typetesting pressure4 th 1,5 times the maximum working pressure5 th6 th 1,0 bar7 th7 th (aereal connections) 0,1 bar• the testing result is positive if there are no pressure drops caused by leakagesafter stabilization of testing conditions and for at least 24 hours except thevariations due to temperature effect. For branch connections, it is foreseenthe possibility to reduce the period of the testing up to 4 hours or 30 minutesif the pipeline respects the stated requirements;• a report must be drawn up for each test containing the test registrationdiagram.75Pipelinetesting