TECHNICAL MANUAL - Sharq.biz

TECHNICAL MANUAL - Sharq.biz

TECHNICAL MANUAL - Sharq.biz

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

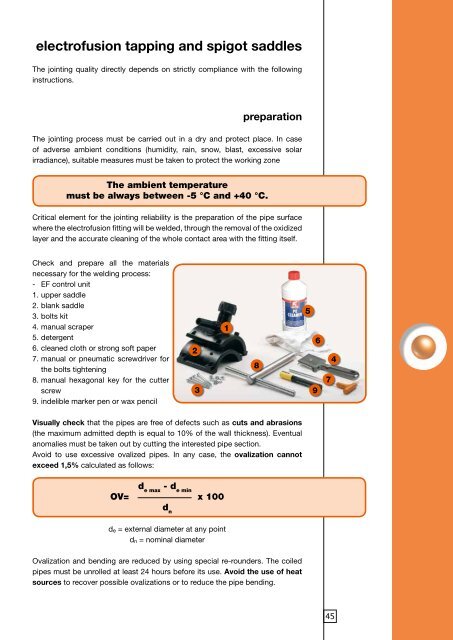

electrofusion tapping and spigot saddlesThe jointing quality directly depends on strictly compliance with the followinginstructions.preparationThe jointing process must be carried out in a dry and protect place. In caseof adverse ambient conditions (humidity, rain, snow, blast, excessive solarirradiance), suitable measures must be taken to protect the working zoneThe ambient temperaturemust be always between -5 °C and +40 °C.Critical element for the jointing reliability is the preparation of the pipe surfacewhere the electrofusion fitting will be welded, through the removal of the oxidizedlayer and the accurate cleaning of the whole contact area with the fitting itself.Check and prepare all the materialsnecessary for the welding process:- EF control unit1. upper saddle2. blank saddle3. bolts kit4. manual scraper5. detergent6. cleaned cloth or strong soft paper7. manual or pneumatic screwdriver forthe bolts tightening8. manual hexagonal key for the cutterscrew9. indelible marker pen or wax pencil231859674Visually check that the pipes are free of defects such as cuts and abrasions(the maximum admitted depth is equal to 10% of the wall thickness). Eventualanomalies must be taken out by cutting the interested pipe section.Avoid to use excessive ovalized pipes. In any case, the ovalization cannotexceed 1,5% calculated as follows:OV=d e max- d e mind nx 100d e = external diameter at any pointd n = nominal diameterOvalization and bending are reduced by using special re-rounders. The coiledpipes must be unrolled at least 24 hours before its use. Avoid the use of heatsources to recover possible ovalizations or to reduce the pipe bending.45