TECHNICAL MANUAL - Sharq.biz

TECHNICAL MANUAL - Sharq.biz

TECHNICAL MANUAL - Sharq.biz

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

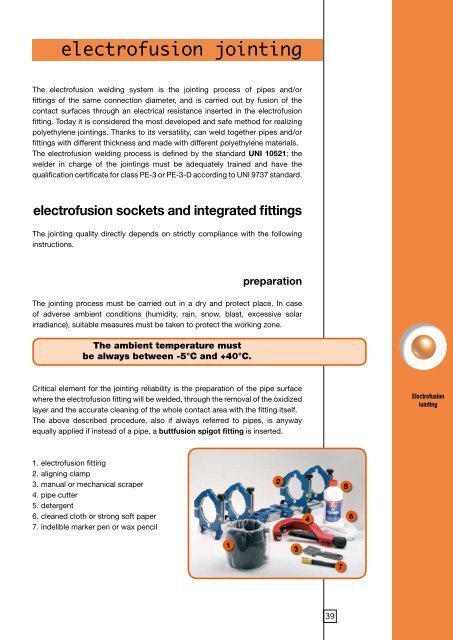

electrofusion jointingThe electrofusion welding system is the jointing process of pipes and/orfittings of the same connection diameter, and is carried out by fusion of thecontact surfaces through an electrical resistance inserted in the electrofusionfitting. Today it is considered the most developed and safe method for realizingpolyethylene jointings. Thanks to its versatility, can weld together pipes and/orfittings with different thickness and made with different polyethylene materials.The electrofusion welding process is defined by the standard UNI 10521; thewelder in charge of the jointings must be adequately trained and have thequalification certificate for class PE-3 or PE-3-D according to UNI 9737 standard.electrofusion sockets and integrated fittingsThe jointing quality directly depends on strictly compliance with the followinginstructions.preparationThe jointing process must be carried out in a dry and protect place. In caseof adverse ambient conditions (humidity, rain, snow, blast, excessive solarirradiance), suitable measures must be taken to protect the working zone.The ambient temperature mustbe always between -5°C and +40°C.Critical element for the jointing reliability is the preparation of the pipe surfacewhere the electrofusion fitting will be welded, through the removal of the oxidizedlayer and the accurate cleaning of the whole contact area with the fitting itself.The above described procedure, also if always referred to pipes, is anywayequally applied if instead of a pipe, a buttfusion spigot fitting is inserted.Electrofusioniointing1. electrofusion fitting2. aligning clamp3. manual or mechanical scraper4. pipe cutter5. detergent6. cleaned cloth or strong soft paper7. indelible marker pen or wax pencil254 613739