TECHNICAL MANUAL - Sharq.biz

TECHNICAL MANUAL - Sharq.biz

TECHNICAL MANUAL - Sharq.biz

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

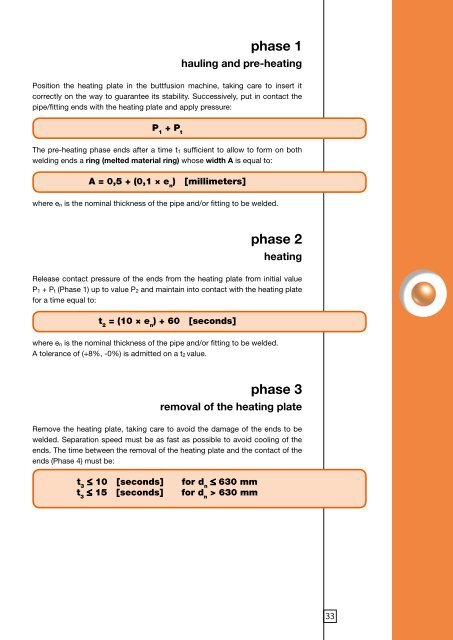

phase 1hauling and pre-heatingPosition the heating plate in the buttfusion machine, taking care to insert itcorrectly on the way to guarantee its stability. Successively, put in contact thepipe/fitting ends with the heating plate and apply pressure:P 1+ P tThe pre-heating phase ends after a time t 1 sufficient to allow to form on bothwelding ends a ring (melted material ring) whose width A is equal to:A = 0,5 + (0,1 × e n) [millimeters]where e n is the nominal thickness of the pipe and/or fitting to be welded.phase 2heatingRelease contact pressure of the ends from the heating plate from initial valueP 1 + P t (Phase 1) up to value P 2 and maintain into contact with the heating platefor a time equal to:t 2= (10 × e n) + 60 [seconds]where e n is the nominal thickness of the pipe and/or fitting to be welded.A tolerance of (+8%, -0%) is admitted on a t 2 value. phase 3removal of the heating plateRemove the heating plate, taking care to avoid the damage of the ends to bewelded. Separation speed must be as fast as possible to avoid cooling of theends. The time between the removal of the heating plate and the contact of theends (Phase 4) must be:t 3≤ 10 [seconds]t 3≤ 15 [seconds]for d n≤ 630 mmfor d n> 630 mm33