TECHNICAL MANUAL - Sharq.biz

TECHNICAL MANUAL - Sharq.biz

TECHNICAL MANUAL - Sharq.biz

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

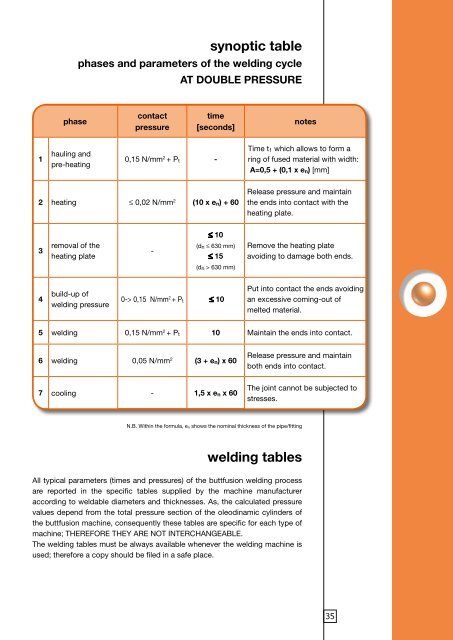

synoptic tablephases and parameters of the welding cycleAT DOUBLE PRESSUREphasecontactpressuretime[seconds]notes1hauling andpre-heating0,15 N/mm 2 + P t -Time t 1 which allows to form aring of fused material with width:A=0,5 + (0,1 x e n ) [mm]2 heating ≤ 0,02 N/mm 2 (10 x e n ) + 60Release pressure and maintainthe ends into contact with theheating plate.3removal of theheating plate-≤ 10(d n ≤ 630 mm)≤ 15Remove the heating plateavoiding to damage both ends.(d n > 630 mm)4build-up ofwelding pressure0-> 0,15 N/mm 2 + P t ≤ 10Put into contact the ends avoidingan excessive coming-out ofmelted material.5 welding 0,15 N/mm 2 + P t 10 Maintain the ends into contact.6 welding 0,05 N/mm 2 (3 + e n ) x 60Release pressure and maintainboth ends into contact.7 cooling - 1,5 x e n x 60The joint cannot be subjected tostresses.N.B. Within the formula, e n shows the nominal thickness of the pipe/fittingwelding tablesAll typical parameters (times and pressures) of the buttfusion welding processare reported in the specific tables supplied by the machine manufactureraccording to weldable diameters and thicknesses. As, the calculated pressurevalues depend from the total pressure section of the oleodinamic cylinders ofthe buttfusion machine, consequently these tables are specific for each type ofmachine; THEREFORE THEY ARE NOT INTERCHANGEABLE.The welding tables must be always available whenever the welding machine isused; therefore a copy should be filed in a safe place.35