TECHNICAL MANUAL - Sharq.biz

TECHNICAL MANUAL - Sharq.biz

TECHNICAL MANUAL - Sharq.biz

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

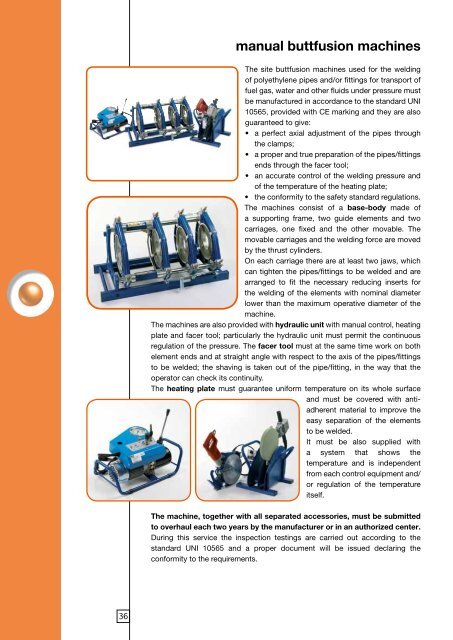

manual buttfusion machinesThe site buttfusion machines used for the weldingof polyethylene pipes and/or fittings for transport offuel gas, water and other fluids under pressure mustbe manufactured in accordance to the standard UNI10565, provided with CE marking and they are alsoguaranteed to give:• a perfect axial adjustment of the pipes throughthe clamps;• a proper and true preparation of the pipes/fittingsends through the facer tool;• an accurate control of the welding pressure andof the temperature of the heating plate;• the conformity to the safety standard regulations.The machines consist of a base-body made ofa supporting frame, two guide elements and twocarriages, one fixed and the other movable. Themovable carriages and the welding force are movedby the thrust cylinders.On each carriage there are at least two jaws, whichcan tighten the pipes/fittings to be welded and arearranged to fit the necessary reducing inserts forthe welding of the elements with nominal diameterlower than the maximum operative diameter of themachine.The machines are also provided with hydraulic unit with manual control, heatingplate and facer tool; particularly the hydraulic unit must permit the continuousregulation of the pressure. The facer tool must at the same time work on bothelement ends and at straight angle with respect to the axis of the pipes/fittingsto be welded; the shaving is taken out of the pipe/fitting, in the way that theoperator can check its continuity.The heating plate must guarantee uniform temperature on its whole surfaceand must be covered with antiadherentmaterial to improve theeasy separation of the elementsto be welded.It must be also supplied witha system that shows thetemperature and is independentfrom each control equipment and/or regulation of the temperatureitself.The machine, together with all separated accessories, must be submittedto overhaul each two years by the manufacturer or in an authorized center.During this service the inspection testings are carried out according to thestandard UNI 10565 and a proper document will be issued declaring theconformity to the requirements.36